1. The unit of measurement for magnetic beads is Ohms, not “hunter,” a detail that requires special attention. The nominal unit indicates the impedance at a specific frequency, usually provided in ohms. The frequency versus impedance characteristic curve is typically available in magnetic bead databases, often referenced at 100MHz. For instance, “1000R@100MHz” signifies an impedance equivalent to 600 ohms at 100MHz.

2. A typical filter comprises lossless reactive components. Its role in the circuit is to reflect the stopband frequencies back to the signal source, hence it’s also known as a reflection filter. When the impedance of the reflection filter mismatches with that of the signal source, some energy gets reflected back, thereby amplifying the interference level. To mitigate this drawback, ferrite magnetic rings or bead sleeves can be employed at the filter inlet to convert high-frequency components into heat through eddy current losses. Consequently, these magnetic rings and beads effectively absorb high-frequency components, earning them the moniker of absorption filters.

Different ferrite suppression elements exhibit optimal suppression within varying frequency ranges. Generally, higher permeability correlates with lower suppression frequencies. Moreover, larger ferrite volumes tend to offer better suppression effects. Among ferrite shapes of equal volume, longer and thinner ones typically provide superior suppression compared to shorter, thicker shapes. Additionally, smaller inner diameters enhance suppression effectiveness. However, in scenarios involving DC or AC bias currents, the performance of EMI-absorbing magnetic rings or beads in suppressing differential mode interference directly depends on their volume. Imbalances can lead to saturation, thereby diminishing their effectiveness.

In suppressing common mode interference, where both positive and negative wires of the power supply pass through a magnetic ring simultaneously, the element exhibits significant inductance towards common mode signals while remaining ineffective against differential mode signals. An effective approach involves winding wires through the magnetic ring multiple times to increase inductance, leveraging the principle of electromagnetic interference suppression effectively.

The ferrite suppression element shall be installed close to the interference source. For the input/output circuit, it should be positioned as near as possible to the inlet and outlet of the shielding shell. When using an absorption filter composed of ferrite magnetic rings and magnetic beads, attention should be paid not only to the high permeability of consumable materials but also to their application. These components typically exhibit resistance to high-frequency components in the range of 10 to several hundred ohms. Therefore, their impact on high impedance circuits is minimal. Conversely, they prove highly effective in low impedance circuits such as power distribution, power supply, or RF circuits.

IV. Conclusion

Ferrite is widely utilized in EMI control due to its ability to attenuate higher frequencies while allowing lower frequencies to pass nearly unimpeded. Magnetic rings and beads used for EMI absorption can be fashioned into various shapes and are extensively employed across different scenarios. On PCBs, for instance, they can be incorporated into DC/DC modules, data lines, power lines, etc., to absorb high-frequency interference signals. Importantly, their use does not introduce new zeros or poles into the system, preserving system stability. When used in conjunction with power filters, they effectively complement the high-frequency performance lacking in typical filters, thereby enhancing overall system filtering characteristics.

Magnetic beads are specifically designed to suppress high-frequency noise and transient interference on signal and power lines. They also possess the capability to absorb electrostatic pulses.

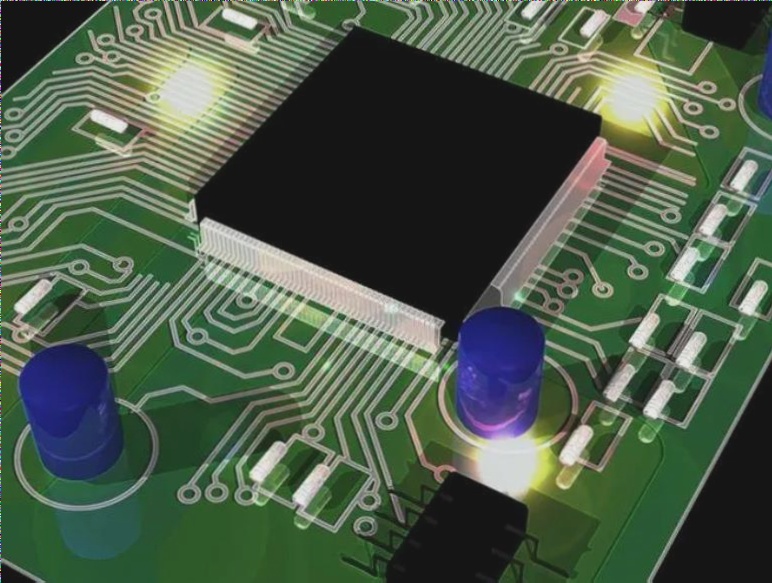

Magnetic beads are used for absorbing UHF signals. For instance, in RF circuits, PLLs, oscillation circuits, and UHF memory circuits (DDR, SDRAM, Rambus, etc.), magnetic beads should be integrated into the power input section. In contrast, inductors function as energy storage elements and find application in LC oscillation circuits and medium-to-low frequency filter circuits, with their operational frequency range seldom exceeding 50MHz.

The primary function of magnetic beads is to eliminate RF noise present in the transmission line structure (circuit). RF energy constitutes the AC sine wave component superimposed on the DC transmission level. While the DC component represents the required useful signal, RF energy is deemed extraneous. Electromagnetic interference propagates along the line (EMI). To mitigate such unnecessary signal energies, chip magnetic beads serve as high-frequency resistors (attenuators), allowing DC signals to pass through while filtering AC signals. Typically, their effective range spans frequencies above 30MHz, though they can impact lower frequencies as well.

Chip magnetic beads are constructed from soft ferrite materials, forming a monolithic structure characterized by high volume resistivity. Eddy current loss in these materials is inversely proportional to their resistivity and directly proportional to the square of the signal frequency. Advantages of chip magnetic beads include compact size and lightweight design. They exhibit high impedance within the RF noise frequency range, effectively eliminating electromagnetic interference from transmission lines. Featuring a closed magnetic circuit structure, they excel in eliminating signal winding. Additionally, they boast excellent magnetic shielding, minimizing DC resistance to prevent excessive attenuation of useful signals. They demonstrate notable characteristics in both high-frequency and impedance domains, effectively combating parasitic oscillations in high-frequency amplifier circuits. They operate efficiently within frequency ranges spanning several megahertz to hundreds of megahertz.

To accurately select magnetic beads, attention must be paid to the following factors:

1. Frequency range of unwanted signals.

2. Source of noise.

3. Required level of noise attenuation.

4. Environmental conditions (temperature, DC voltage, structural strength).

5. Circuit and load impedance.

6. Availability of PCB space for mounting magnetic beads.

The first three considerations can be evaluated by examining the impedance frequency curve provided by the manufacturer. Of particular importance are the resistance, inductive reactance, and total impedance curves. The total impedance is described by Z = √(R² + (2πfL)²). This curve aids in selecting a magnetic bead model with maximum impedance within the desired frequency attenuation range, while minimizing signal attenuation at low frequencies and DC levels. Note that excessive DC voltage or high operating temperatures, along with large external magnetic fields, can adversely affect the impedance characteristics of magnetic beads.

When deciding between chip magnetic beads and chip inductors, the choice largely hinges on the application. Chip inductors are suitable for resonant circuits, whereas chip magnetic beads are preferred for eliminating unwanted EMI noise. Applications for chip magnetic beads and chip inductors include:

– Chip inductors: Radio frequency (RF) and wireless communication, information technology equipment, radar detectors, automotive applications, cellular telephones, pagers, audio equipment, PDAs (personal digital assistants), wireless remote control systems, and low-voltage power supply modules.

– Chip magnetic beads: Filtering between clock generation circuits, analog and digital circuits, I/O internal connectors (such as serial and parallel ports, keyboards, mice), long-distance telecommunications, local area networks, RF circuits interfacing with easily disturbed logic equipment, and filtering high-frequency conducted interference in power supply circuits, computers, video cassette recorders (VCRs), and EMI noise suppression in TV systems and mobile phones.