Processing Metallized Half-Holes on PCB Sides

Introduction

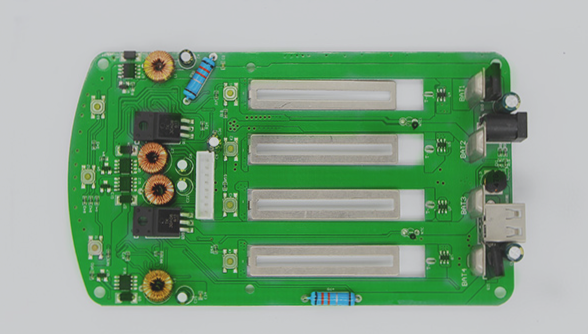

With the continuous evolution of electronic devices, customers are increasingly demanding diverse specifications for metallized half-holes on PCB sides. The quality of these half-holes significantly impacts installation and usage. This article delves into the processing of metallized half-holes on PCB sides through secondary molding and drilling, highlighting the techniques and control methods involved.

Principle of Mechanical Processing

When it comes to drilling or milling, the SPINDLE rotates clockwise. At point A, the metallization layer on the hole wall bonds tightly to the base material layer, preventing copper burrs. However, at point B, without ample support, the metallized layer may curl during processing, leading to persistent copper burrs.

PCB Side Half-Hole Product Types

Processing Issues and Improvement Methods

Product types are divided into four groups. For Types 1 and 2 with larger half-hole spacings, a double milling approach is used on both sides. Types 3 and 4, with smaller half-holes, face issues like micro-connection short circuits, which are addressed through design adjustments and the use of new pad PCB boards for support during drilling.

Improving PCB Processing for Better Quality Results

- Standard drill bits may cause drilling issues and breakage at hole edges. Consider using slot drills for better results.

- Secondary drilling on the entire PCB can lead to inconsistencies due to material expansion and contraction during processing.

Enhancements Made:

- Adjusted processing flow to address expansion and contraction issues:

- Original Process: Cutting – Inner Layer Graphics Transfer – Pressing – Primary Drilling – Copper Sinking – Pattern Plating – Outer Layer Graphics Transfer – Solder Mask – Characters – Nickel-Gold Plating – Secondary Drilling – Milling.

- Improved Process: Open Material – Inner Layer Graphics Transfer – Pressing – Primary Drilling – Copper Sinking – Pattern Plating – Outer Layer Graphics Transfer – Solder Mask – Characters – Nickel-Gold Plating – Primary Milling Formation (Outer Frame) – Secondary Drilling – Secondary Milling.

- Implemented a secondary drilling combination method to reduce labor hours and eliminate inconsistencies.

Results of Improvements:

- Quality of half-holes now meets expected targets, ensuring consistency across the entire PCB.

Key Takeaways:

- Optimized PCB design by increasing pad spacing to avoid micro-connection issues.

- Prevented copper edge flipping by optimizing pad PCB board usage frequency.

- Resolved half-hole processing inconsistencies through process and method enhancements.

In conclusion, a comprehensive analysis and improvement approach have led to an overall enhancement of half-hole processing technology.