PCB Soldering: A Complete Guide to Effective and Efficient Soldering

Introduction to PCB Soldering

PCB soldering is the process of attaching components to a printed circuit board (PCB) using various tools such as soldering irons and production equipment. This guide focuses on manual soldering techniques, specifically on the use and maintenance of soldering irons.

1. How to Use a PCB Soldering Iron

- Preparation and Setup

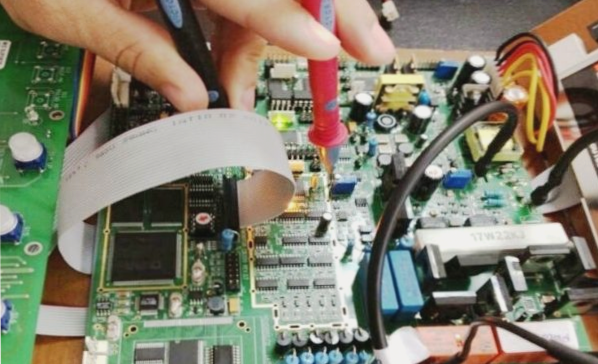

- Hold the Soldering Iron Correctly: Ensure a firm grip with your right hand while using needle-nose pliers or tweezers with your left hand to hold components in place on the PCB.

- Preheat the Soldering Iron: Allow the soldering iron to preheat fully before starting to ensure optimal solder melting.

- Tin the Soldering Iron Tip: Apply a small amount of solder to the tip to enhance heat transfer and prevent oxidation.

- Soldering Process

- Positioning the Soldering Iron: Angle the tip at approximately 60° relative to the PCB surface for efficient heat transfer.

- Solder Application: Ensure smooth solder flow onto the joint, limiting contact time to 2-3 seconds to prevent damage.

2. Maintenance and Safety Tips

- Regular Cleaning of the Tip

- Clean the Tip Frequently: Wipe the tip on a damp sponge or use a brass cleaner to prevent solder buildup.

- Tip Care and Replacement

- Avoid Excessive Pressure: Prevent tip damage by not applying excessive pressure during soldering.

- Replace Worn Tips: Inspect and replace worn tips to maintain optimal performance.

- Temperature Control and Safety

- Use the Correct Temperature: Adjust the soldering iron temperature based on the solder type, typically between 350°C and 400°C.

- Safety Precautions: Wear safety glasses, work in a ventilated area, and handle the hot iron cautiously to prevent accidents.

Soldering Process and Quality Control

After soldering, lift the iron tip while holding the component to allow the solder to solidify for a reliable connection. Trim excess leads for a neat finish. Ensure bright, smooth joints without excess solder for high-quality connections.

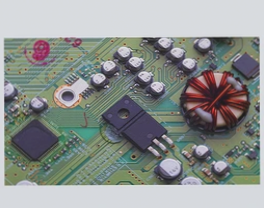

Good Contact

- The solder must fuse effectively with both the component lead and the PCB pad to ensure a solid and well-formed joint.

- Avoid common issues like cold soldering or dry joints:

- Cold Soldering: Occurs when insufficient solder is applied, leading to poor electrical contact and potential intermittent connection problems.

- Dry Soldering: Happens when the solder doesn’t properly fuse with the component or pad, making the joint weak and easily breakable.

Timing and Heat Control

- Avoid overheating the circuit board as it can cause damage like burning or lifting the copper traces.

- When desoldering, use the soldering iron tip to heat the joint until the solder melts, then gently remove the component from the board.

Soldering Iron Maintenance

To ensure your soldering iron’s longevity and performance, follow these maintenance tips:

- Cleaning and Preparation: Clean the tip daily before use to remove impurities and ensure optimal heat transfer.

- Proper Handling: Avoid excessive pressure on the tip to prevent damage and reduce heat efficiency.

- Avoid Rough Surfaces: Refrain from rubbing the tip on abrasive surfaces to maintain its quality.

- Use Proper Flux: Choose flux free of chlorine or acid to prevent corrosion and damage to the iron tip and PCB components.

- Re-tinning the Tip: Clean and re-tin the tip after each use to preserve its quality and store the iron properly.

Important Tips for Using a Soldering Iron

- Initial Preparation: Condition a new soldering iron before use by heating and applying solder to the tip for optimal performance.

- Temperature Control: Avoid overheating the tip to prevent oxidation and wear, ensuring a longer lifespan.

- Safety Precautions: Keep the iron away from combustible materials and check the power cord for damage to avoid hazards.

- Avoid Physical Impact: Handle the iron carefully to prevent damage to internal components that can lead to malfunction.

- Tip Maintenance: Clean the tip regularly to remove oxidation and buildup, considering replacement if severely damaged.

Conclusion

Adhering to proper soldering techniques and iron maintenance practices is crucial for strong, reliable, and safe electrical connections. By following these guidelines and ensuring quality control, you can enhance the performance and longevity of both your soldering iron and circuit boards.