The Significance of High-Frequency PCBs in Modern Electronics

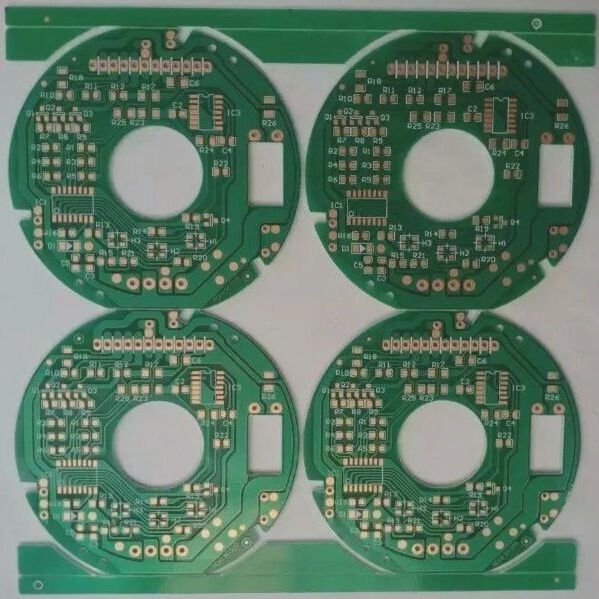

- High-frequency PCBs are specially designed for elevated electromagnetic frequencies, ideal for applications above 300 MHz or wavelengths shorter than 1 meter.

- These boards are crucial for devices operating in the microwave frequency range, including those in the millimeter-wave spectrum up to 30 GHz.

- As technology advances, the demand for high-frequency boards with exceptional material standards continues to grow.

- Key characteristics of high-frequency PCBs include outstanding electrical properties, chemical stability, and minimal signal loss.

Applications and Processing Techniques of High-Frequency PCBs

- High-frequency PCBs find uses in mobile communication devices, power amplifiers, and various passive components like couplers and filters.

- They play a vital role in automotive collision avoidance systems, satellite communication, and radio systems, reflecting the trend towards higher frequencies in electronics.

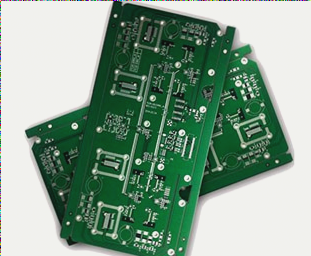

- Classification of high-frequency boards includes materials like Rogers’ 4350B/4003C and Arlon’s 25N/25FR.

- Processing methods involve careful drilling and machining to maintain the integrity of the boards.

- Materials such as PTFE from manufacturers like Rogers and Arlon are used, requiring precise cutting and protective film handling.

Optimizing High-Frequency PCB Manufacturing Processes

- During drilling and machining, it is essential to use new drill bits and apply the correct pressure for optimal results.

- Post-drilling, clearing dust from holes with an air gun ensures a clean surface for further processing.

- Plasma treatment or sodium naphthalene activation can enhance hole metallization for improved performance.

- Attention to detail in processes like PTH sinking copper and solder mask application is critical for the board’s functionality.

- Effective gong board processing and careful burr trimming are essential to protect the substrate and copper surface.

- Following a precise sequence of steps, including inspection, etching, and testing, ensures the quality of the final high-frequency PCB product.

Challenges in High-Frequency PCB Processing

- Immersion Copper: Achieving complete copper coverage on the walls of the holes poses a significant challenge.

- Line Gap Control: Precise management of gaps and prevention of sand holes during image transfer, etching, and line width adjustment are crucial.

- Green Oil Process: Ensuring proper adhesion of the green oil and effectively controlling foaming are vital tasks.

- Surface Integrity: Maintaining stringent control over board surface scratches at every processing stage is imperative.

Stay updated on the latest techniques and technologies to overcome these challenges in high-frequency circuit board processing!

العربية

العربية 简体中文

简体中文 Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 한국어

한국어 Português

Português Русский

Русский Español

Español ไทย

ไทย