**Learn to Decrypt by Understanding PCB Chip Encryption**

1. **Chip Grinding:** Use fine sandpaper to carefully grind off the model number on the chip. This is particularly effective for partial gate chips. For commonly used chips, attackers only need to deduce a general function, identify which pins are grounded, and easily connect to the power source to compare it with the genuine chip.

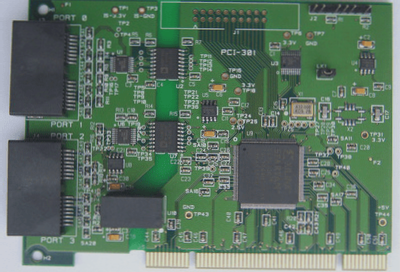

2. **Sealing Glue:** Apply a type of adhesive that solidifies to a stone-like consistency (such as epoxy or ceramic-based glue) to coat the entire PCB circuit board and its components. You might also consider deliberately creating several flying wires (preferably thin enameled wire) twisted together. This will likely cause the thief to break these wires while attempting to remove the glue, leaving them uncertain about how to reconnect. It’s important that the glue is non-corrosive and that the enclosed area does not generate excessive heat.

3. **Dedicated Encryption Chip:** Utilize a specialized encryption chip, such as the ATMEL AT88SC153, which costs only a few dollars. As long as the software remains uncrackable, even if thieves intercept all signals using a logic analyzer, they will not be able to replicate the entire signal set.

4. Utilize unbreakable chips, such as EPLD’s EPM7128 or higher, and ACTEL’s CPLD; however, these options come at a higher cost (over one hundred yuan), making them unsuitable for smaller products.

5. Employ MASK ICs, which are generally much more difficult to crack compared to programmable chips, requiring significant production volumes. MASK ICs extend beyond MCUs to include ROMs, FPGAs, and other dedicated chips.

6. Use bare chips, ensuring that their model numbers are obscured and the wiring is not easily discernible. The functionality of the chip should not be too straightforward to deduce; it is advisable to include additional components in the vicinity, such as small ICs, resistors, etc.

7. Connect a resistance of 60 ohms or higher in series on the signal line with a low current (to prevent the multimeter from beeping), which will complicate the thief’s efforts when measuring the connection relationships.

8. Incorporate more small components without labels (or only minimal codes) for signal processing, such as small chip capacitors, TO-XX diodes, transistors, and small chips with three to six pins; identifying their true nature will be challenging.

9. Cross some address and data lines (excluding RAM, which will need corresponding adjustments in the software) to prevent thieves from easily making assumptions when testing connections.

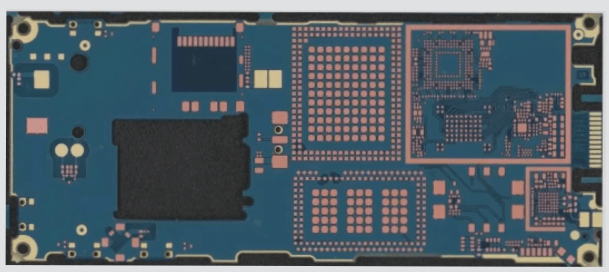

10. Employ buried and blind via technologies on the PCB, concealing vias within the board. This method is more expensive and is suitable only for high-end PCB products.

11. Utilize specialized accessories, such as custom LCD screens, tailored transformers, SIM cards, and encrypted disks.

12. Apply for a patent. Given the challenging landscape of intellectual property protection, this approach is often the most preferred internationally.

PCB manufacturers should master PCB chip encryption techniques and understand decryption methods to enhance PCB production quality. Regular training for employees will improve their expertise in this area.

If you have any PCB manufacturing needs, please do not hesitate to contact me.Contact me