-

-

-

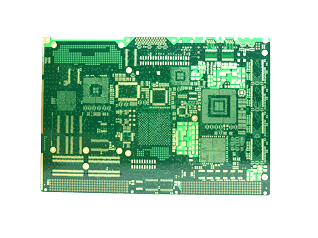

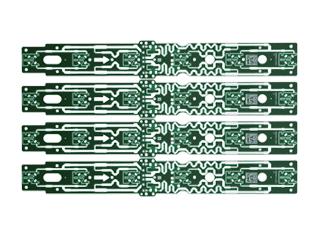

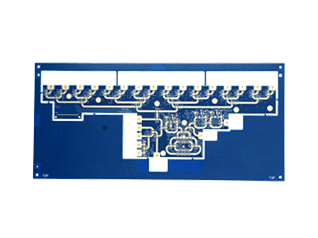

- Medical PCB

8-layer high-frequency mixing pressure mechanical blind hole PCB

Rated 0 out of 5Read more -

-

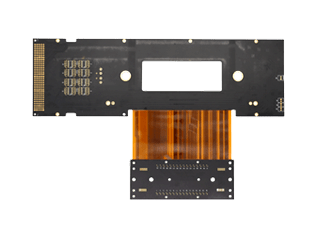

The medical and healthcare PCB products we provide

WellCircuits fabricates and assembles medical PCBs that are suitable for a broad array of medical devices like:

- Medical imaging devices

- Medical monitoring systems

- Robotic surgery

- Radiotherapy or radiation therapy

- Blood press monitor

The testing standards we follow for medical PCBs

We conduct continuous testing at every step of the production process to ensure the reliability of the medical circuit boards.

- Automatic optical inspection (AOI): AOI takes pictures of the PCB by using one 2D camera and/or two 3D cameras. The image captured is then checked against the schematic. If the circuit does not conform to the schematic, the board goes through manual inspection.

- Solderability tests ensure that the solder joints are safe.

- Testing for ionic contamination: Ionic contamination testing is carried out to find Ionic residues that result from the process of fabrication and soldering.

- Peel Test: Determines the measure of strength needed to peel the laminate off the board circuit.

- Micro-sectioning analysis The examination is conducted to assess the condition on the circuit board and to detect internal faults.

- Test of flying probes: The test probe is moved from test points to different test points and then checked for shorts, openings, and other issues.

- Reflectometer in the time-domain (TDR): TDR impedance measurements are vital to verify the integrity of the signal. It also monitors for electrical irregularities in connectors or another electrical pathway.

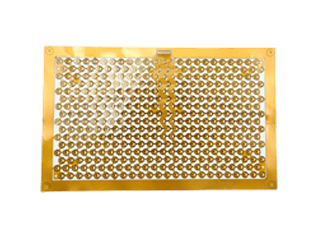

What can we do to ensure your highest reliability requirements by providing 100% traceability

As per IPC-6012 class 2 and Class 3, we design and build basic, advanced micro and standard boards that have high quality and precision. The advanced boards have UL Standard 94 V-0 for flammability. We offer the following documentation and certifications:

- Certificate of conformity

- Specifications on the material

- First Article Inspection Report

- Reflow Profile Copy (included in the article that begins)

- Requirements for photos

- IPC J-STD-001E

- Documentation of all calibrated tools employed during the manufacturing process.

- Report of AOI or visually inspected report

- Testing in circuits or using a flying probe Report

- The report of the Ionic Cleansing Test

The following guidelines are followed which help us create high-quality and reliable medical PCBs to the medical and healthcare business.

- IPC 6011 Specification for performance of classes 1, class 2, and PCBs of class 3

- IEC 60601-1 The general requirements to ensure fundamental safety and performance of electrical medical equipment

- IEC 60601-1-2 Definition of electromagnetic needs (EMI as well as EMF) in medical PCBs

- ISO 1335:2016: Provides quality management systems for medical equipment

We provide DFM/DFA check-ups on each board.

We focus on DFM as well as DFA analysis to prevent problems and provide an internal quality inspection system that guarantees no-defect boards. We also offer engineering assistance to determine if the product is performing in the way you expect and is IPC class 3 certified if you choose to use the IPC class 3.

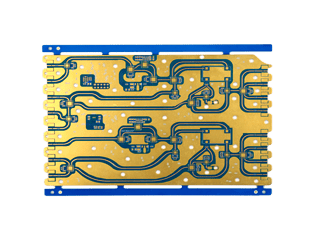

Comprehensive electrical testing of medical PCBs

We are not compromising in terms of quality. We adhere to the strict fabrication guidelines that medical boards must meet, which means continuous testing at every step of the production process, including cross-sections and AOI tests, BGA X-ray, flying probes, and various other electrical tests.

Fantastic and all assembly within one building

Miscommunication between the separate factories and assembly facilities can lead to delays in delivery and errors in the board. A PCB manufacturer who doesn’t manage assembly will not run DFA checks to verify that the board will be assembled properly. Only one vendor is accountable.

How do I get a price for medical PCBs

We can run DFM/DFA analyses to assist you. We will provide you with an analysis report. It is possible to upload your data safely through our site.

The following details are required to be able to offer you the following quote:

- Gerber, ODB++ or IPC-2581

- BOM if you require assembly

- Quantity

- Time to turn