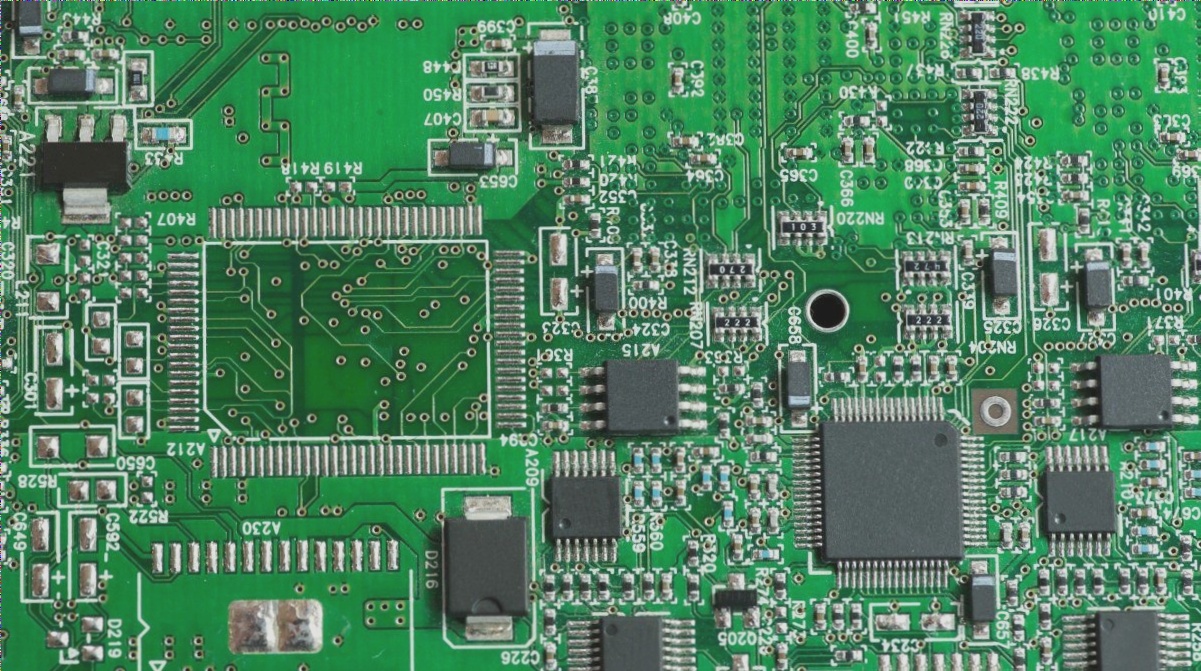

Effective Methods for Disassembling Integrated Circuits in PCB Copying and Maintenance

Disassembling integrated circuits is a critical step in PCB copying and circuit maintenance processes. It involves splitting the circuit board, removing the integrated circuit, and creating a BOM list. Here are several effective methods for accurately disassembling integrated circuits:

- Solder Sucker Disassembly Method: This method uses a solder sucker and a 35W+ electric soldering iron. The solder is melted with the iron, and then sucked away, allowing for the safe removal of the integrated block.

- Medical Hollow Needle Disassembly Method: Using medical hollow needles, the pins of the integrated block are covered and soldered. After solidification, the pins are removed one by one, facilitating the disassembly process.

- Electric Soldering Iron Brush Coordination Disassembly Method: In this approach, a soldering iron is used to melt the solder on the pins, while a brush is used to wipe it off. This method can be used alone or in combination with other techniques for complete disassembly.

- Adding Solder Melting and Disassembly Method: This time-saving method involves adding solder to the pins to connect the joints. Heating the pins with an electric soldering iron allows for easy removal using tweezers or a screwdriver.

- Multi-Strand Copper Wire Suction Tin Removal Method: This technique utilizes multi-strand copper wire to absorb solder from the integrated circuit pins. By applying rosin alcohol solution and heating the wires, the solder can be completely removed, aiding in the disassembly process.

WellCircuits Limited specializes in high-precision circuit boards, including HDI, backplanes, rigid-flex combinations, and more. Our quality products cater to a wide range of customer needs in the PCB industry.