High-Frequency PCB Boards: Everything You Need to Know

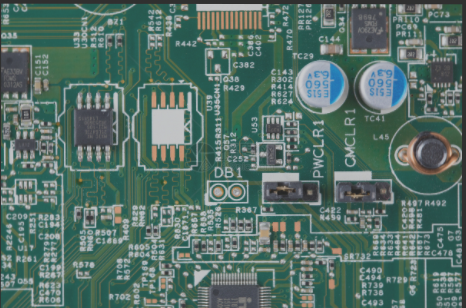

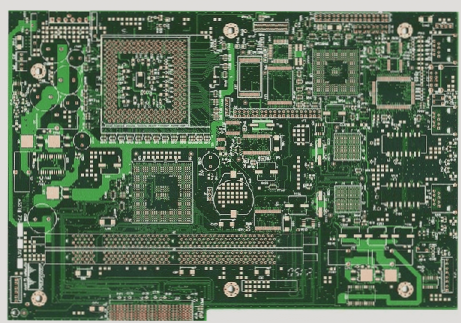

Definition and Classification

A high-frequency PCB board is a specialized type designed to operate at electromagnetic frequencies higher than 300 MHz or wavelengths shorter than 1 meter. These boards are crucial for microwave applications exceeding 3 GHz or wavelengths less than 0.1 meter.

Classification includes RO4350B/4003C, Arlon 25N/25FR, and Taconic TLG series B. Processing methods resemble standard FR4 PCB manufacturing, with Rogers PCB materials offering ceramic high-frequency PCB board series:

- RO3000 series: Features ceramic-filled PTFE circuit materials like RO3003, RO3006, RO3010, and RO3035.

- RT6000 series: Utilizes ceramic-filled PTFE circuit materials for high dielectric constant circuits, such as RT6006 and RT6010.

- TMM series: Composite materials based on ceramics, hydrocarbons, and thermosetting polymers, including TMM3, TMM4, TMM6, TMM10, TMM10i, and TMM13i.

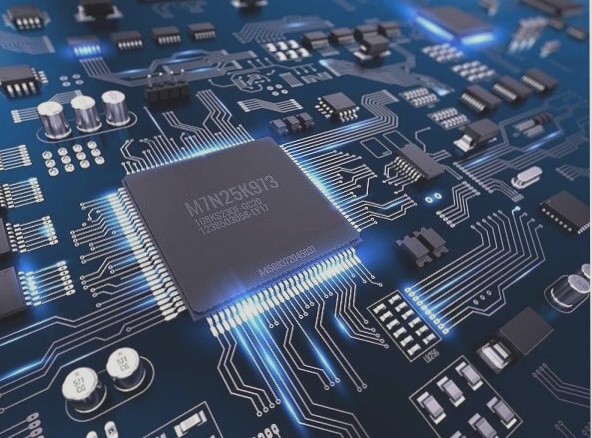

Current Trends and Demand

The demand for high-frequency electronic equipment is rising due to advancements in wireless networks and satellite communications. Products are moving towards higher speeds and frequencies, with communication systems like satellite systems and mobile phone base stations requiring high-frequency PCBs for efficient transmission.

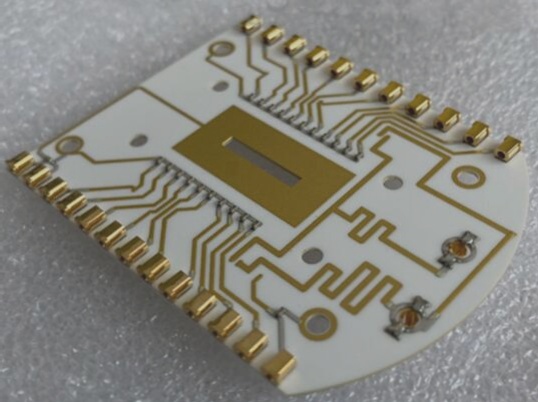

Challenges in Processing

- Copper sinking: Ensuring proper copper plating on hole walls.

- Control of pattern transfer, etching precision, line widths, gaps, and avoiding pinholes.

- Solder mask application: Ensuring adhesion and preventing foaming.

- Rigorous control of surface scratches throughout processing stages.

Substrate materials must possess excellent electrical properties and chemical stability to minimize losses as signal frequencies increase, emphasizing the critical role of high-frequency PCB boards in modern electronics.