PCBA Conformal Coating Inspection Guide

1. Conformal Coating

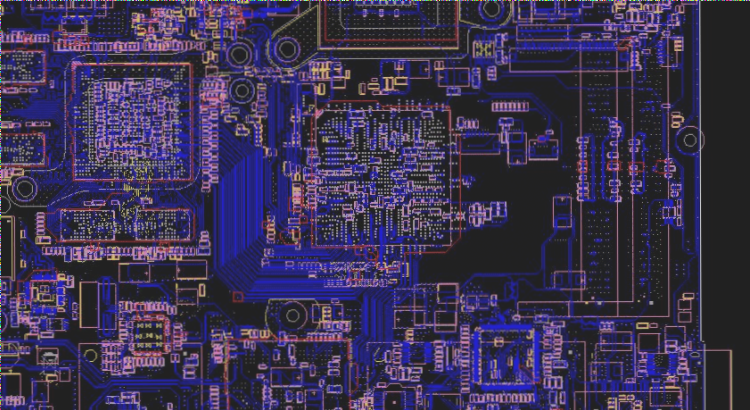

Conformal coating on a printed circuit board assembly (PCBA) should be transparent and evenly cover the board and components. The coating method affects the uniformity, which impacts the appearance and condition of the board. During SMT chip processing, dip-coated components may show paint buildup or air bubbles, which typically do not affect functionality. How can you check the quality of PCBA conformal coating?

2. Coating Layer Inspection

The coating on the PCB should be visually inspected. Coatings with fluorescent substances can be checked in dim light, with white light used as an additional inspection aid.

Goals:

- Achieve good adhesion on PCBA components without cavitation or air bubbles.

- Avoid semi-wetting, dusting, peeling, wrinkling, cracking, ripples, fish-eye, or orange peel on the PCBA.

- Ensure no foreign matter, discoloration, or loss of clarity, with a fully cured and uniform coating.

Acceptable Criteria:

- Uniform, fully cured coating with appropriate coverage.

- No adhesion to solder mask, voids, bubbles, cracks, fish-eye, or orange peel on the PCB.

- Foreign objects should not impact components or soldering.

Defects to Watch For:

- Uncured, sticky coating, missed areas requiring coating, or coating absence where needed.

- Loss of adhesion, voids, bubbles, cracks, fish eyes, or peeling causing circuit exposure.

- Discoloration or loss of transparency.

3. Thickness Measurement

Measure the coating thickness using the same material as the PCBA or non-porous materials like metal or glass. Wet film thickness measurement is a common method based on dry/wet film thickness conversion relationships to determine the final coating thickness.