How to Determine the Number of Layers in a PCB

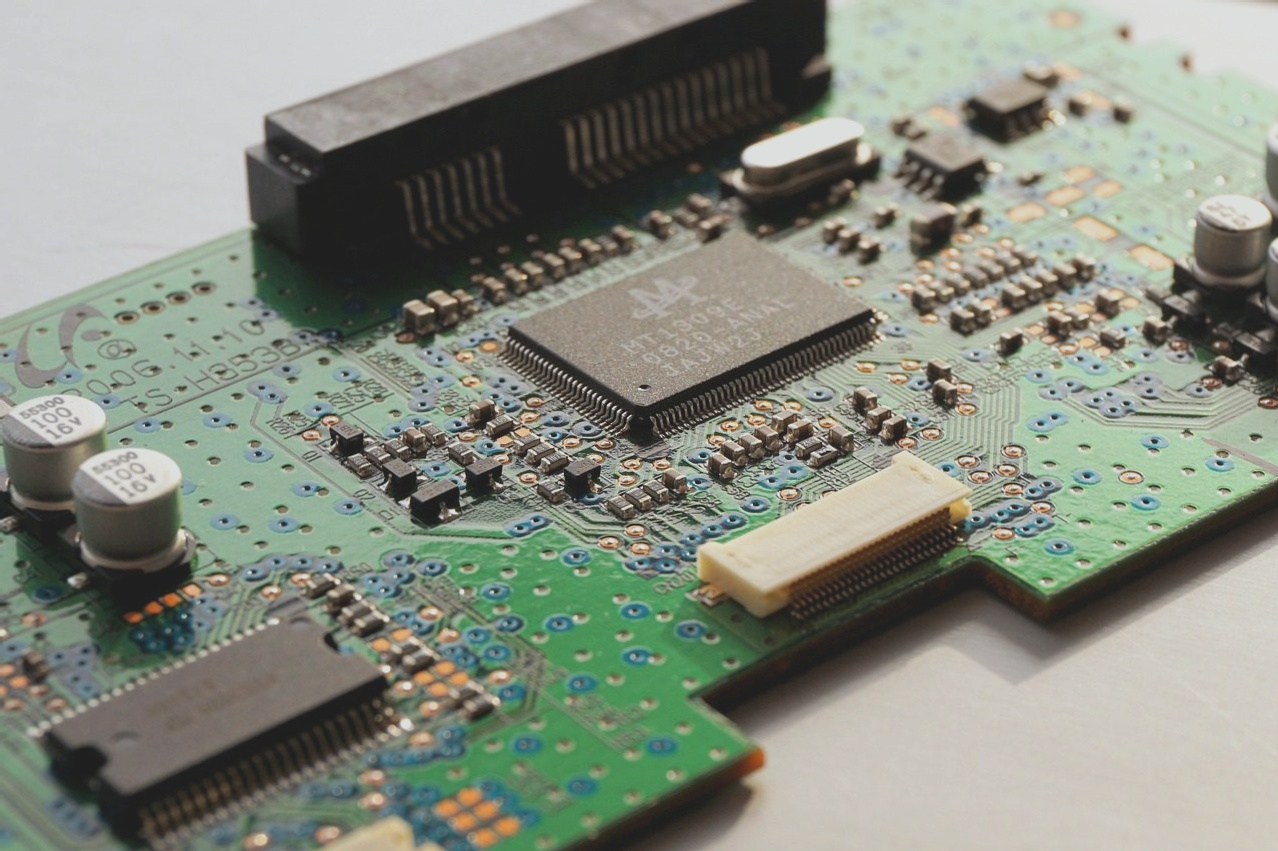

Visual Inspection

While it may be challenging to visually identify the number of layers in a PCB, looking for white insulating layers between PCB layers can provide some clues. Multi-layer PCBs consist of single or double-sided boards with insulating layers in between. These insulating layers help prevent electrical shorts and offer a simple way to visually estimate the number of layers.

Guide Hole and Blind Hole Alignment Method

The guide hole method involves examining the via holes on a PCB to determine the number of layers. For example, on a 4-layer PCB, wiring is on the first and fourth layers, with inner layers serving different purposes. Guide holes that are visible on one side but not the other can indicate a 6 or 8-layer board.

Some manufacturers use buried and blind vias to connect internal layers without passing through the entire board. Light-blocking vias can help distinguish between 4-layer and 6-layer (or more) PCBs, but this method is not always reliable.

Accumulation Method

By analyzing traces and component placement on well-known PCBs, one can estimate the layer count. For example, comparing older graphics card models with newer ones can reveal differences in design that may indicate the number of layers. While past methods like measuring thickness are not always accurate, industry insights can provide valuable clues.

The Impact of PCB Layers on Design

The number of PCB layers plays a crucial role in the design process. For instance, a minimum of six layers is usually necessary for dual-CPU setups. This setup includes 3 or 4 signal layers, 1 ground layer, and 1 or 2 power layers. Such a configuration ensures proper signal isolation, reduces interference, and provides sufficient power supply.

On the other hand, a 4-layer PCB design is typically adequate for most general applications. Opting for a 6-layer design can be overly expensive without offering significant performance enhancements.

If you are in need of PCB manufacturing services, feel free to reach out to me for assistance. Contact me