Techniques to Detect Hidden Errors in PCB Copy Board Software

When it comes to software development projects, identifying software defects is crucial. Traditional techniques like code inspection, structural testing, and functional testing are essential but may not be enough to catch all hidden errors in today’s complex systems.

Structural Testing (White Box Testing)

Structural testing, also known as white box testing, is effective in uncovering logic errors, control flow issues, calculation mistakes, and data inconsistencies in the code. This type of testing provides a detailed view of the software structure by checking every conditional expression, mathematical operation, input, and output.

Code Reviews

Code reviews are similar to structural testing and help identify implementation flaws and potential issues. They involve thorough inspections of each individual unit of the software to catch any errors or inefficiencies in the code.

Functional Testing (Black Box Testing)

Functional testing, or black box testing, focuses on testing the software’s outputs based on controlled inputs without knowledge of the internal implementation. It is effective in uncovering unmet requirements, interface issues, performance problems, and errors in frequently used functions of the program.

While these techniques can identify many errors, they have limitations. Code reviews and white box testing focus on small portions of the code, while black box testing treats the system as a whole. Some critical issues can only be identified by analyzing how components interact within the entire system.

Potential Problem Areas:

- Stack Overflow

- Race Conditions

- Deadlock

Common in systems using multi-tasking real-time design techniques, these problems require thorough analysis to prevent system failures.

Stack Overflow

Stack overflow can lead to unpredictable program behavior and severe system failures if the stack exceeds the allocated range. Analyzing code, determining maximum stack usage under all conditions, and verifying adequate stack size are essential to prevent stack overflow.

Stack depth analysis involves constructing call trees for each independent thread, determining stack usage of each function, identifying the call path requiring the most stack space, and adding up the maximum stack usage for each thread’s call tree.

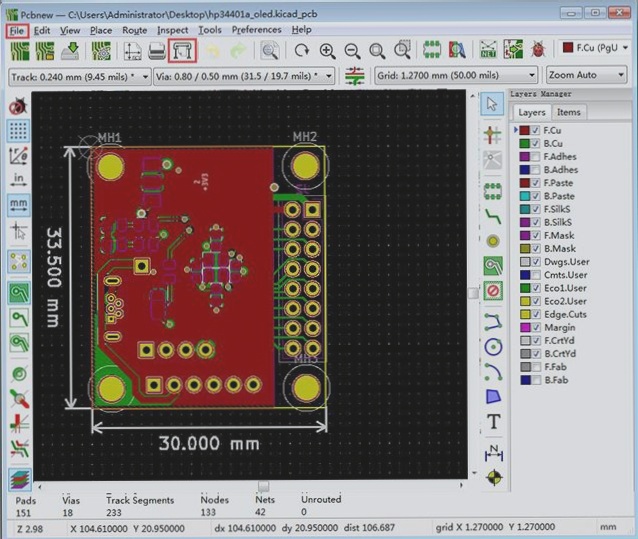

Important Considerations for PCB Layout and Design

- Determine the maximum stack usage for each interrupt service routine (ISR) at every interrupt priority level and calculate the total stack usage.

- Include the stack space needed to preserve the processor state during an interrupt for each priority in PCB layout and design.

- Account for the maximum stack space required for the Real-Time Operating System (RTOS) internal operations if utilized.

It is crucial to consider the impact of runtime library functions on stack usage. Compilers often optimize operations, leading to calls that are only visible in the generated assembly language. These functions can significantly impact stack space and should be analyzed. In C++, functions like constructors, destructors, overloaded operators, copy constructors, and conversion functions must be included in the call tree. Additionally, function pointers and their referenced functions should be evaluated for stack usage.

If you have any inquiries regarding PCB, feel free to reach out to us at info@wellcircuits.com.