PCB History

- At the turn of the 20th century, electronic components were interconnected by wires before printed circuit boards (PCBs) emerged. Researchers sought ways to simplify electronic equipment production, reduce wiring complexity, and cut costs by replacing wires with printed circuits.

- In 1903, German inventor Albert Hanson introduced a flat foil conductor laminated onto an insulating board. Thomas Edison experimented with plating conductors onto linen paper chemically in 1904.

- In 1913, Arthur Berry filed a patent in the UK for printing and etching techniques.

- In 1927, Charles Ducas from the US patented a method for electroplating circuit patterns.

- In 1936, Austrian inventor Paul Eisler pioneered foil technology in the UK, incorporating a PCB into a radio device, resembling modern PCB technology.

- In 1941, German magnetic mines utilized multilayer printed circuits.

- In 1943, the US military adopted PCB technology for radios.

- By 1948, the US began using PCBs for commercial purposes.

- Since the mid-1950s, PCBs have been widely adopted.

- Paul Eisler’s first radio featured a printed circuit chassis and an antenna coil.

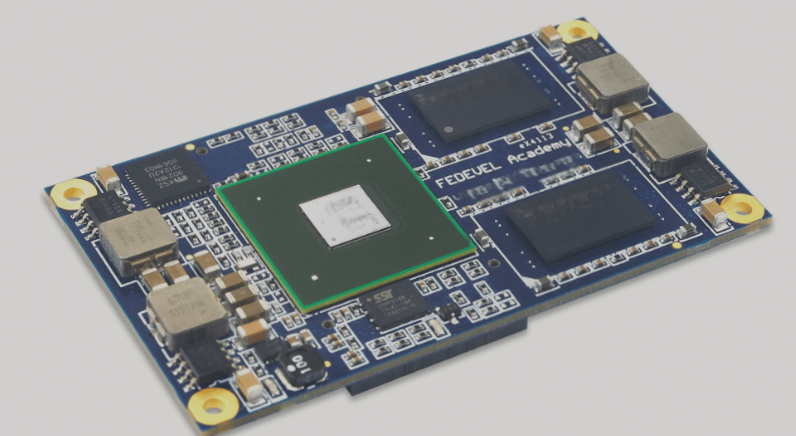

PCB Development

Printed boards have evolved from single-layer to double-sided, multi-layer, and flexible designs, continuing to follow these development trends. Ongoing advancements in precision, density, reliability, size reduction, cost efficiency, and performance enhancement ensure that PCBs will play a vital role in future electronic equipment development.

Discussions on the future of printed board manufacturing technology focus on high density, precision, fine apertures, wires, pitches, reliability, multilayer structures, high-speed transmission, lightweight, and thin types. Improvements aim to boost productivity, cut costs and pollution, and cater to multi-variety, small-batch production. The technical development of printed circuits is gauged by line width, aperture, and plate thickness-to-aperture ratio.

Four Inspection Methods for Circuit Board Repair

1. Observation and Testing

Start circuit board repair inspections with a visual examination to prevent secondary damage when powered. Identify and address general external issues through visual inspection.

- Man-made causes: Check for broken or deformed corners, correct chip orientation, forced breaks in chip sockets, and proper insertion of circuit boards with short-circuit terminals.

- Burning reasons: Inspect resistors, capacitors, and diodes for burn damage; check integrated circuits for bulges, cracks, burns, or discoloration; look for peeled or burned traces; ensure copper holes are aligned with the pad; and check for burned fuses and thermistors.

2. Static Detection

If no issues are found visually, use a multimeter to troubleshoot main components and key points.

- Check for power supply and ground short circuits using a multimeter and a 5V power supply chip.

- Test diode functionality by measuring positive and negative poles for breakdown due to excessive current.

- Assess capacitor condition by measuring capacitance to detect short or open circuits and determine if the issue lies with the component or the connected circuit.

- Verify component logic performance by testing integrated circuits, transistors, resistors, and inspecting the resistance row of the bus structure.

3. Live Detection

Primarily utilized by PCB manufacturers, this method involves a general debugging platform to test the circuit board. If issues persist, live detection is employed.

- Check for overheating components by powering on the circuit board and ensuring each chip’s temperature is normal. Replace any overheating components and verify their functionality.

PCB Troubleshooting Tips

- Confirm PCB gate circuit logic: Utilize an oscilloscope to measure the gate circuit. If the output does not match the expected level, it could indicate a damaged chip.

- Test crystal oscillator output: Check the crystal oscillator output using an oscilloscope. Absence of output may indicate oscillator damage.

- Verify digital circuit functionality: Use an oscilloscope to measure the digital circuit and ensure the signal is functioning correctly.

- Online Testing: Compare the faulty circuit board with a known functional one to identify differences.