Chip Programming and PCBA Processing Technology

Chip Programming Overview

Chip programming involves transferring programs from a computer to a chip IC through burning. Common types of chip programming include PROM and EPROM.

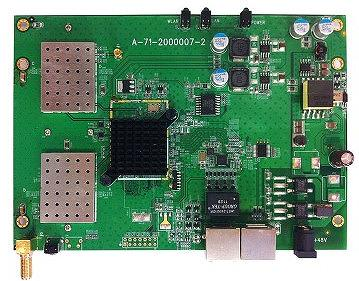

PCBA Technology Advancements

PCBA processing technology is advancing rapidly, with applications expanding across various industries. From mobile phones to cars, PCBA is integral to modern devices.

Hardware and Software Collaboration

To ensure optimal design functionality, hardware and software collaboration is crucial in PCBA processing. With the rise of intelligent products, customized programs are in high demand, necessitating chip programming.

Chip Burning Methods

Chip burning involves writing programs into a chip’s internal storage using a burning tool. The process includes offline and online burning methods.

Chip Offline Programming

- Compatible with various chip packages through adapters

- Requires specific adapters for different chips and packages

- Time-consuming and costly for reprogramming

- Risk of chip deformation during disassembly

Chip PCBA Online Programming

- Uses standard communication buses like USB, SWD, JTAG

- Requires fewer pins for connection

- Allows immediate reprogramming without chip removal

- Enhances production line automation and efficiency

Online programming is crucial in assessing process accuracy, production efficiency, and quality control in the PCBA manufacturing industry.