Conditioning the Whole Hole

Conditioning the hole involves preparing the walls of drilled holes for subsequent processes, ensuring they are hydrophilic and positive before the Plated Through Hole (PTH) process begins. This step is crucial for proper treatment in PCB fabrication.

Desmearing

Desmearing is the removal of resin smear that can hinder electrical connection in the PTH process. Resin residue left on hole walls after drilling can create barriers between copper layers, affecting bonding and conductivity.

Dichromate Treatment

Cr2O7, also known as heavy chromate, plays a key role in PCB treatment. This compound distinguishes itself with unique properties that aid in the manufacturing process.

Etchback

Etchback is a technique used in multi-layer PCB manufacturing to deliberately etch back resin and fiberglass substrate between copper ring layers of through-hole walls. This process, known as “etchback,” ensures proper layer alignment and connectivity.

Free Radical

Free radicals are highly reactive charged particles crucial in processes like plasma etching for PCBs. By generating radicals in a controlled environment, debris can be effectively removed from hole walls without damaging copper components.

Negative Etch-back

Negative etch-back, once used in military-grade PCBs, involved etching dielectric layers to enhance reliability. While this process can improve connection strength, errors in etching can lead to issues like the shrinking of inner copper rings, impacting overall PCB quality.

Plasma

Plasma, the fourth state of matter, is a high-energy mixture of gases used in PCB manufacturing for processes like plasma etching. This unique state of matter dissociates into ions and radicals, offering precise cleaning and treatment capabilities for intricate PCB designs.

Reverse Etchback

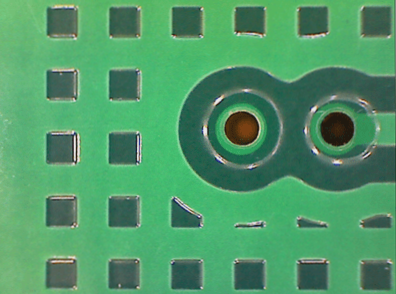

Reverse Etchback in PCBs

Reverse etchback occurs when the inner copper ring of a through-hole in a multi-layer PCB is unintentionally etched, causing the inner edge of the ring to recede from the hole wall. As a result, the base material, composed of resin and fiberglass, forms a protrusion. In this case, the inner copper ring diameter becomes larger than the drilled hole diameter. This situation, known as “anti-erosion back,” can result in unreliable interconnections between the inner copper ring and the hole wall. To improve reliability, the base material must be set back, and the copper ring should be deliberately positioned to protrude, creating a more solid connection with the hole wall. This process is called “etchback,” and the reversed outcome is known as “reverse etchback.”

Shadowing in PCB Manufacturing

In the PCB industry, shadowing is used in two distinct contexts. The first relates to infrared (IR) soldering during the assembly of surface-mount devices (SMDs) on a PCB. Here, some components may block infrared radiation, preventing heat from reaching certain areas, resulting in incomplete soldering. This is known as “shadowing.” The second refers to a situation during resin etchback (Etchback) of high-performance multi-layer PCBs, where resin remains in the “dead corners” at the top and bottom of the inner copper ring. These areas are often difficult to clean, and the residual resin can form a shadow, hindering the etchback process.

Swelling Agents for PCBs

Swelling agents, or leavening agents, are used after drilling multi-layer PCBs to facilitate the removal of glue residue from the hole walls. The board is immersed in a high-temperature alkaline solution containing organic solvents to soften the glue, making it easier to remove.

Yield in PCB Manufacturing

Yield refers to the percentage of products that pass quality inspection in a production batch. It is a measure of the efficiency and success of the manufacturing process, with a higher yield indicating fewer defects and better overall quality. If you have any PCB manufacturing needs, please do not hesitate to contact me.