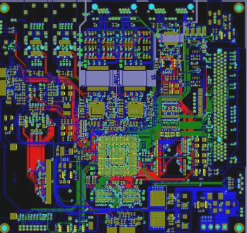

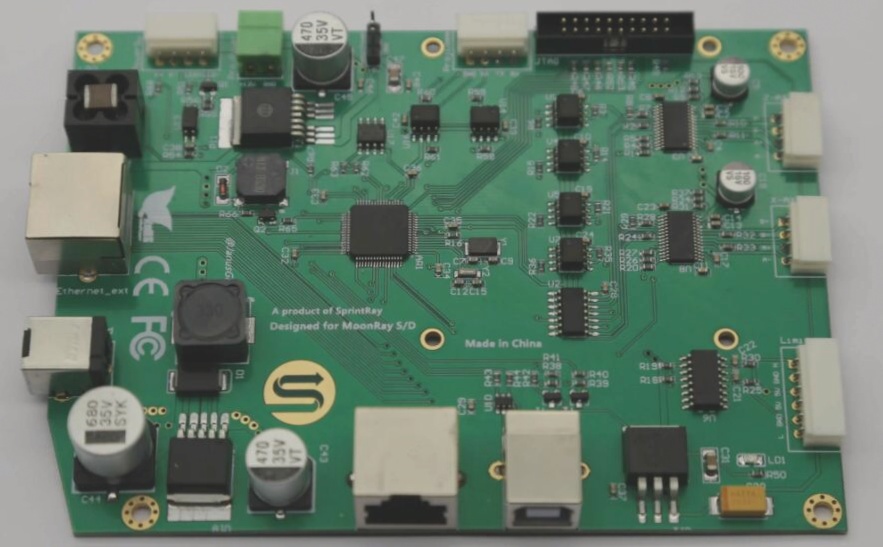

In the design of PCB boards, anti-ESD protection can be achieved through layering, proper layout, and installation. Most design modifications during the process involve adding or removing components in anticipation of ESD events. By adjusting the layout of the PCB, ESD can be effectively prevented. Below are some common precautions to take:

1. Use multi-layer PCB boards whenever possible. Compared to double-sided PCBs, multi-layer boards with ground and power planes, along with closely spaced signal lines and ground lines, can reduce common-mode impedance and inductive coupling. This can result in achieving a level of ESD protection equivalent to 1/10 to 1/100 of that of double-sided PCBs.

2. Place each signal layer as close to a power or ground layer as possible. For high-density PCBs that have components on both the top and bottom surfaces, short interconnects, and numerous ground fills, consider utilizing inner layers for additional protection.

For a double-sided PCB board, tightly weave power and ground grids together. Ensure power wires are placed near ground wires with multiple connections between vertical and horizontal wires or padding. Keep grid size on one side less than or equal to 60mm, aiming for less than 13mm if possible. Ensure each circuit is as compact as possible, minimizing connectors. If feasible, route power cables through the card center away from ESD-affected areas. Below connectors leading out of the chassis that are prone to ESD, place wide chassis grounds or polygon fills on all PCB layers and connect them with vias spaced approximately 13mm apart. Add mounting holes at the card edge with solder-free top and bottom pads around them to connect to the chassis ground. No solder should be applied to these pads during assembly. Screw the PCB board tightly to the metal chassis/shield or bracket with screws incorporating washers. Maintain a 0.64mm isolation area between the chassis ground and the circuit ground on each layer. Connect the chassis ground and circuit ground with a 1.27mm wide wire every 100mm along the chassis ground wire at the top and bottom layers near the mounting holes. Include pads or mounting holes adjacent to these connection points to facilitate mounting between the chassis ground and circuit ground. Optionally, use ferrite beads/high-frequency capacitors for these ground connections.

If the board won’t be enclosed in a metal chassis or shield, exclude solder resist from the top and bottom chassis grounds to act as discharge electrodes for ESD arcs. To implement a ring ground around the circuit:

1) Around the entire periphery, create a ring ground path in addition to the edge connector and chassis ground.

2) Ensure a minimum annular width of 2.5mm on all layers.

3) Connect the rings with vias spaced 13mm apart.

4) Link the ring ground to the common ground of the multilayer circuit.

5) For double-sided panels in shielded environments, link the ring ground to the circuit common ground. For unshielded circuits, link it to the chassis ground. Exclude solder resist from the ring ground so it can discharge ESD. Introduce at least one 0.5mm wide gap in the ring ground on all layers to avoid a large loop. Maintain a minimum 0.5mm separation between signal wiring and the ring ground.

Near signal lines in ESD-prone areas, include a ground wire. Position I/O circuits close to corresponding connectors and place ESD-susceptible circuits centrally for shielding from other circuits. Include a series resistor and magnetic bead on the receiving end, and consider adding them on the driving end for easily hit cable drivers. Install transient protectors mainly on the receiving end. Use a short, thick wire to connect to the chassis or circuit ground and attach the transient protector before connecting to the rest of the circuit. Place filter capacitors at the connector or within 25mm of the receiving circuit. Ensure signal wires are minimized in length, adding a ground line in parallel for signal lines over 300mm. Change positions of signal and ground lines on long signal lines every few centimeters to reduce loop area. Transmit signals from a central location to multiple receive circuits. Place high-frequency capacitors near power pins of IC chips. Add a high-frequency bypass capacitor within 80mm of each connector. Fill unused areas with ground when possible, connecting fills of all layers every 60mm. Connect large ground fill areas at both endpoints with a wire if opening length exceeds 8mm. Avoid placing reset or edge-triggered signal lines near the PCB edge. Link mounting holes to the circuit common or isolate them.

1) Use a zero-ohm resistor for connections when using a metal bracket with a metal shield or chassis.

2) Determine mounting hole size for reliable installation of metal or plastic brackets, using large pads on top and bottom layers. Skip solder resist on bottom pads and prevent them from being wave soldered.

Do not run protected and unprotected signal lines in parallel or near each other, especially for reset, interrupt, and control signals. Filter high frequencies, maintain a distance from input/output circuits, and stay clear of the board edge. Insert the PCB into the chassis rather than an opening or internal seam. Be cautious of routing under beads, between pads, and signal lines contacting the bead, as some beads conduct electricity and may create unexpected paths. Place static-sensitive PCBs in the middle when multiple boards are housed in a case or motherboard.

1. Use multi-layer PCB boards whenever possible. Compared to double-sided PCBs, multi-layer boards with ground and power planes, along with closely spaced signal lines and ground lines, can reduce common-mode impedance and inductive coupling. This can result in achieving a level of ESD protection equivalent to 1/10 to 1/100 of that of double-sided PCBs.

2. Place each signal layer as close to a power or ground layer as possible. For high-density PCBs that have components on both the top and bottom surfaces, short interconnects, and numerous ground fills, consider utilizing inner layers for additional protection.

For a double-sided PCB board, tightly weave power and ground grids together. Ensure power wires are placed near ground wires with multiple connections between vertical and horizontal wires or padding. Keep grid size on one side less than or equal to 60mm, aiming for less than 13mm if possible. Ensure each circuit is as compact as possible, minimizing connectors. If feasible, route power cables through the card center away from ESD-affected areas. Below connectors leading out of the chassis that are prone to ESD, place wide chassis grounds or polygon fills on all PCB layers and connect them with vias spaced approximately 13mm apart. Add mounting holes at the card edge with solder-free top and bottom pads around them to connect to the chassis ground. No solder should be applied to these pads during assembly. Screw the PCB board tightly to the metal chassis/shield or bracket with screws incorporating washers. Maintain a 0.64mm isolation area between the chassis ground and the circuit ground on each layer. Connect the chassis ground and circuit ground with a 1.27mm wide wire every 100mm along the chassis ground wire at the top and bottom layers near the mounting holes. Include pads or mounting holes adjacent to these connection points to facilitate mounting between the chassis ground and circuit ground. Optionally, use ferrite beads/high-frequency capacitors for these ground connections.

If the board won’t be enclosed in a metal chassis or shield, exclude solder resist from the top and bottom chassis grounds to act as discharge electrodes for ESD arcs. To implement a ring ground around the circuit:

1) Around the entire periphery, create a ring ground path in addition to the edge connector and chassis ground.

2) Ensure a minimum annular width of 2.5mm on all layers.

3) Connect the rings with vias spaced 13mm apart.

4) Link the ring ground to the common ground of the multilayer circuit.

5) For double-sided panels in shielded environments, link the ring ground to the circuit common ground. For unshielded circuits, link it to the chassis ground. Exclude solder resist from the ring ground so it can discharge ESD. Introduce at least one 0.5mm wide gap in the ring ground on all layers to avoid a large loop. Maintain a minimum 0.5mm separation between signal wiring and the ring ground.

Near signal lines in ESD-prone areas, include a ground wire. Position I/O circuits close to corresponding connectors and place ESD-susceptible circuits centrally for shielding from other circuits. Include a series resistor and magnetic bead on the receiving end, and consider adding them on the driving end for easily hit cable drivers. Install transient protectors mainly on the receiving end. Use a short, thick wire to connect to the chassis or circuit ground and attach the transient protector before connecting to the rest of the circuit. Place filter capacitors at the connector or within 25mm of the receiving circuit. Ensure signal wires are minimized in length, adding a ground line in parallel for signal lines over 300mm. Change positions of signal and ground lines on long signal lines every few centimeters to reduce loop area. Transmit signals from a central location to multiple receive circuits. Place high-frequency capacitors near power pins of IC chips. Add a high-frequency bypass capacitor within 80mm of each connector. Fill unused areas with ground when possible, connecting fills of all layers every 60mm. Connect large ground fill areas at both endpoints with a wire if opening length exceeds 8mm. Avoid placing reset or edge-triggered signal lines near the PCB edge. Link mounting holes to the circuit common or isolate them.

1) Use a zero-ohm resistor for connections when using a metal bracket with a metal shield or chassis.

2) Determine mounting hole size for reliable installation of metal or plastic brackets, using large pads on top and bottom layers. Skip solder resist on bottom pads and prevent them from being wave soldered.

Do not run protected and unprotected signal lines in parallel or near each other, especially for reset, interrupt, and control signals. Filter high frequencies, maintain a distance from input/output circuits, and stay clear of the board edge. Insert the PCB into the chassis rather than an opening or internal seam. Be cautious of routing under beads, between pads, and signal lines contacting the bead, as some beads conduct electricity and may create unexpected paths. Place static-sensitive PCBs in the middle when multiple boards are housed in a case or motherboard.