As operating speeds increase, EMI becomes increasingly problematic and manifests in various forms (such as interference in interconnections). High-speed devices are particularly vulnerable to this issue, often picking up high-speed false signals, while low-speed devices may ignore such spurious signals.

At the same time, EMI poses a significant threat to the safety, reliability, and stability of electronic systems. Therefore, when designing electronic products, it is critical to carefully consider the PCB layout to address and mitigate EMI concerns.

Definition of Electromagnetic Interference (EMI)

**Electromagnetic Interference (EMI)**, which stands for ElectroMagnetic Interference, can be classified into two categories: radiated interference and conducted interference. Radiated interference occurs when the interference source uses space as a medium to disrupt signals between different electrical networks. On the other hand, conducted interference involves using conductive media to transmit interference from one electrical network to another. In high-speed system design, common sources of radiated interference in PCB design include integrated circuit pins, high-frequency signal traces, and various connectors. The electromagnetic waves they emit contribute to EMI, which can adversely affect the performance of both the interfering and affected systems.

### PCB Design Techniques for EMI Reduction

1. **Common Mode EMI Interference Source**

(For example, the voltage drop caused by transient voltages formed on the power bus at the inductive ends of the decoupling path)

Using low-value inductors in the power layer helps to reduce the transient signals generated by inductors, thereby minimizing common-mode EMI.

– Minimize the length of traces between the power plane and the IC power pin.

– Use 3-6 mil layer spacing in the PCB and FR4 as the dielectric material.

2. **Reducing Loop Area**

Every loop acts like an antenna, so it’s crucial to minimize the number of loops, the area of each loop, and their antenna effects. Ensure that any two points in the signal path have a single loop route, avoid creating artificial loops, and make use of the power plane whenever possible.

3. **Filtering**

Filters are effective in reducing EMI both on power lines and signal lines. Three common methods include:

– **Decoupling Capacitors**

– **EMI Filters**

– **Magnetic Components**

These filters can be strategically placed to suppress unwanted interference and improve the overall electromagnetic compatibility of the system.

4. **Electromagnetic Shielding**

Place signal traces on the same PCB layer, as close as possible to the power or ground layers, to reduce EMI radiation.

The power plane should ideally be positioned close to the ground plane to enhance shielding effectiveness.

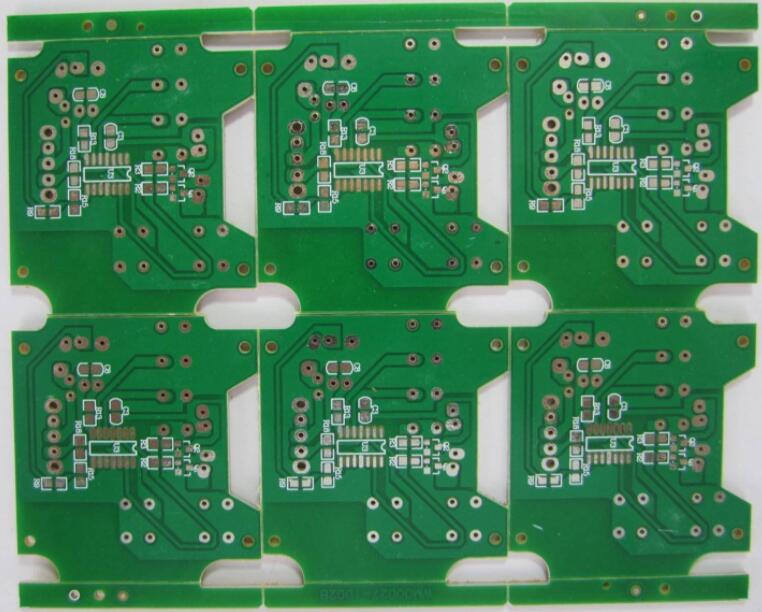

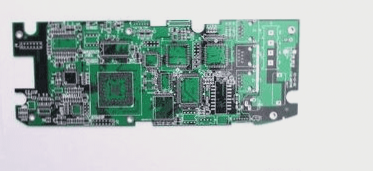

5. **Component Layout**

(Different layouts can affect the circuit’s susceptibility to interference and its ability to resist it)

– Organize components based on function (e.g., demodulation circuits, high-frequency amplifiers, mixing circuits).

– Separate strong and weak electrical signals, and ensure that digital and analog circuits are isolated.

– Position the filter networks of each section close to their respective components to reduce radiation and enhance immunity to interference.

– Components sensitive to interference should be arranged away from sources of EMI, such as positioning the CPU away from data-processing circuits.

6. **Routing Considerations**

(Improper routing can lead to cross-talk and signal interference)

– Avoid placing traces near the edge of the PCB to prevent breakage during manufacturing.

– Ensure that power traces are sufficiently wide to reduce loop resistance.

– Keep signal traces as short as possible and minimize the number of vias.

– Avoid using right-angle traces; 135° angles are preferable for smoother signal flow.

– Isolate digital and analog circuits with dedicated ground planes, keeping digital and analog grounds separate, and then connecting them to a common power ground.

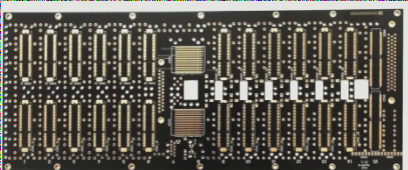

7. **Increasing PCB Dielectric Constant / Thickness**

Increasing the dielectric constant of the PCB can help prevent high-frequency components, such as transmission lines, from radiating outward. Additionally, increasing the thickness of the PCB and reducing the microstrip line thickness can help prevent electromagnetic leakage and further reduce radiation.

If you have any PCB manufacturing needs, please do not hesitate to contact me.Contact me