Non-Nickel PCB Surface Treatment Processes for Multilayer PCBs

- Evolution of Surface Treatment Processes

- Addressing Limitations of HASL

- Alternative Methods to HASL

- Protecting Circuit Copper Foil

- Preventing Oxidation for Soldering

- Utilizing Gold as a Copper Cover

- Importance of Barrier Layer of Nickel

- Requirements for Surface Treatment

The Surface Treatment Process of Non-Electrolytic Nickel PCB

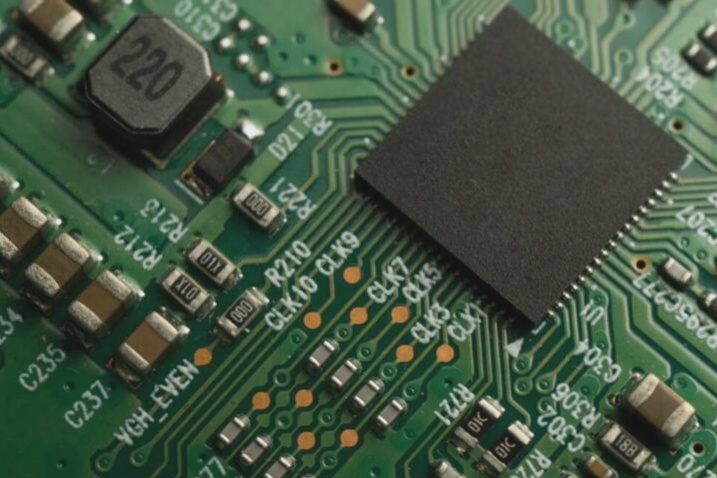

The surface treatment process of non-electrolytic nickel PCBs for multilayer PCBs has evolved significantly in recent years. One key aspect is the gold precipitation on the surface, which establishes a high-strength, electrically reliable connection between circuit boards and components. Gold naturally precipitates on nickel, providing resistance to oxidation during storage. To ensure effective welding connections, the nickel must remain pure to enable gold precipitation.

Another crucial function is hardness, especially for applications like wire bonding and touchpad contact points. Nickel’s hardness is essential to prevent deformation during wire bonding, ensuring processing durability. Additionally, the electrical characteristics of the nickel layer play a role in high-frequency signal performance. Signal loss in microwave PCBs can be influenced by the nickel layer thickness, impacting the electrical signal’s integrity.

Contact resistance is also a critical factor, as the nickel/gold surface must maintain conductivity over the product’s lifespan. Effective external contact conductivity is essential, even after prolonged environmental exposure. Research has quantified the contact requirements for nickel/gold surfaces, emphasizing the importance of long-term conductivity.