Counterfeiting infringes on the legitimate rights of intellectual property owners. The economic losses from counterfeit components far surpass the mere cost of replacing equipment, encompassing safety expenses, performance degradation, maintenance, and damage to reputation. More critically, counterfeit components can lead to severe consequences, as they may be utilized in destructive actions that pose significant national security challenges. The vast global semiconductor market incentivizes some manufacturers to profit from fake components.

With the rapid advancement of electronic information technology, the lifecycle of various electronic components, including plastic encapsulated integrated circuits, is shortening. This trend complicates supply chain management for users, such as complete machine manufacturers, since components or integrated circuits originally designed may no longer be produced. Particularly for niche components, manufacturers with high reliability needs often cannot purchase directly from producers due to low order volumes, necessitating procurement through agents, thereby creating opportunities for counterfeit integrated circuits to infiltrate the supply chain.

Currently, various components of differing quality levels are employed in projects, especially monolithic integrated circuits for specific models, with a significant portion imported and typically sourced through agents. Complex factors such as prohibitions, transportation restrictions, and shutdowns have led to a substantial presence of counterfeit and inferior devices, complicating testing and quality control. Once these fake devices are installed, they can significantly compromise equipment reliability.

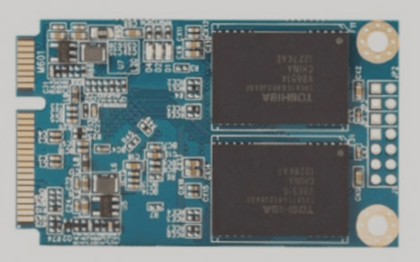

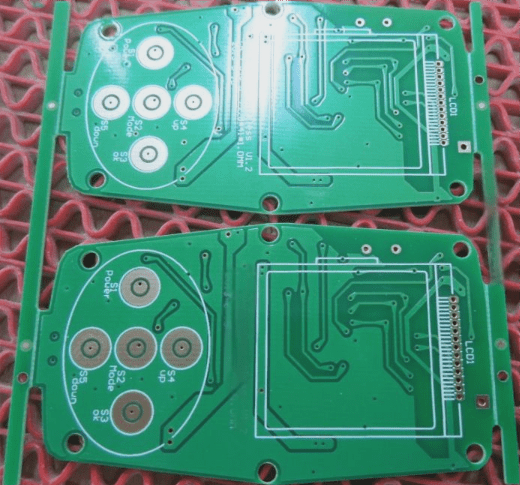

The entry of counterfeit components into the supply chain can severely impact the electronic industry economically. Counterfeiting manifests in various forms: sometimes, original IC logos are ground off and repainted; at other times, counterfeiters produce convincing replicas that can mislead users. Occasionally, the only visible difference is a darker top on the IC package compared to its edges. DPA analysis reveals that while some packages and markings may appear normal, the chips inside are either different or non-existent, or they imitate functional chips that do not originate from the claimed manufacturer. Additionally, some counterfeit devices may have inverted identifications or mismatched pins, while others, despite perfect appearances, contain fake chips that have often been compromised by electrostatic discharge stress, leading to eventual failure.

1. Definition and Hazard Analysis of Counterfeit Electronic Components

1.1 What are Counterfeit Electronic Components?

For electronic component manufacturers, counterfeit components are unauthorized substitutes or copies, or components with undisclosed alterations in materials or performance, failing to meet falsely advertised standards. For electronic component dealers, counterfeit components refer to those produced and distributed in violation of intellectual property, copyright, or trademark laws, which intentionally mislead consumers about product quality through deceptive practices.

1.2 Hazards of Refurbished Counterfeit Plastic Encapsulated ICs

The reliability of refurbished counterfeit plastic encapsulated ICs, aged products, or those with potential damage cannot be assured. They exhibit high early and random failure rates, with undetectable potential failures. Utilizing counterfeit refurbished devices leads to increased early system failure rates, posing several hazards to the reliability and safety of the entire equipment system: First, low-quality components masquerading as high-quality ones may malfunction under extreme conditions; second, refurbished ICs may suffer from prior usage, causing internal interface degradation; and third, the refurbishment process may introduce new damages, such as interface damage during PCBA debonding, mechanical pin damage, surface grinding, corrosive residue from solder treatment, and potential electrostatic discharge harm.

2. DPA Technology

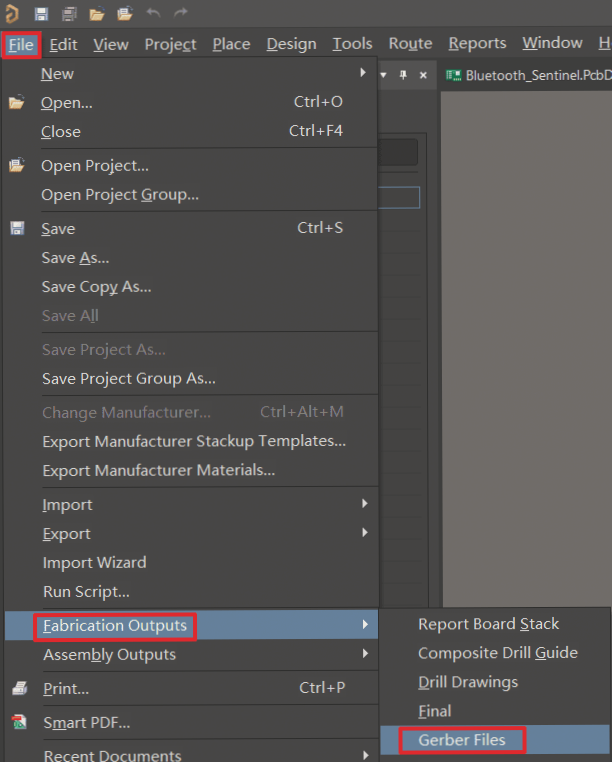

Destructive Physical Analysis (DPA) involves dissecting component samples to confirm whether their design, structure, materials, and manufacturing quality align with intended use or relevant specifications, as well as the reliability and supportability defined for the components. DPA serves as both a confirmation of potential defects and a predictive analysis of component reliability before use. This technology is applicable throughout the component production process, enabling the identification of potential defects in materials and processes. Key applications include:

(1) Analyzing causes of electrical characteristic failures without complete functionality loss;

(2) Quality monitoring during production, especially for critical processes;

(3) Controlling failure modes related to design, structure, assembly, and more;

(4) Identifying reliability risks of electronic components;

(5) Conducting delivery and arrival inspections;

(6) Verifying the authenticity of electronic components.

Typical characteristics of counterfeit integrated circuits, including pin defects and abnormal electrical parameters, can be identified through visual inspections, electrical tests, reliability screenings, and DPA.

3. Suggestions for Whole Machine Users

3.1 Revise Quality Control Specifications for Component Procurement

Amend the quality control specifications for procuring various components to include counterfeit identification as a fundamental requirement when purchasing plastic encapsulated ICs. Currently, many manufacturers hesitate to identify refurbished and counterfeit ICs due to a lack of knowledge and fear of repercussions, especially in industrial electronics where model variety is high but procurement volume is low. A robust identification system is essential to prevent the use of counterfeit ICs in high-reliability electronic equipment.

3.2 Establish a Refurbishment and Counterfeiting Database

Develop a database encompassing identified refurbished and counterfeit models, sharing results within the procurement and quality control systems to mitigate misuse. This database should include “real data” such as international brand IC models, identification meanings, layout structures, and production dates. Although compiling this data requires substantial effort, it can greatly enhance the identification of counterfeit ICs over time. “Fake data,” detailing counterfeiting characteristics, should also be included to improve the timeliness of identification.

3.3 Strengthen Collaboration with Third-Party Technical Institutions

The impact of counterfeit refurbished devices on equipment production and safety is significant. Addressing these challenges requires ongoing efforts and support from specialized technical institutions for professional research, enhancing the capabilities of quality and procurement teams in combating counterfeit devices.

4. Conclusion

Counterfeiting violates the legitimate rights of intellectual property owners, fueled by high profits and weak reporting mechanisms. The risks posed by counterfeit electronic components can lead to safety hazards and various losses for manufacturers and dealers, including reputational damage. The current booming market environment is akin to a haven for counterfeiters. Mitigating this issue requires adherence to fair trade practices and international business norms. Device manufacturers can further reduce counterfeiting risks by implementing anti-counterfeiting technologies and regulatory procedures. OEMs can effectively manage the risk of counterfeit devices through proper prediction and management strategies, but relying on non-authoritative sources is unwise in an era of rapid technological change. Comprehensive licensing and optimized distribution schemes are also vital, albeit challenging to implement.