Flexible PCBs: Innovations in Materials and Technologies

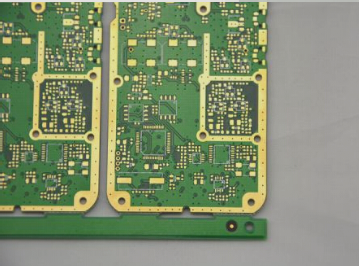

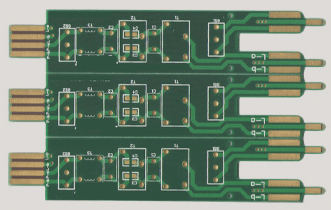

Flexible PCBs, based on flexible substrates that can be bent, have gained popularity in electronic products due to their lightweight and compact nature. The trend towards miniaturization and multifunctionality in electronics is driving PCB manufacturing towards higher density, precision, and speed.

Development Opportunities

- A diversified material system offers manufacturers multiple options for flexible PCB manufacturing.

- Flexible PCB technology is compatible with emerging printed electronics technology.

- Utilizing printing technology for additive manufacturing of circuit boards is an emerging focus area.

- Advances in materials and technology expand the application range of flexible PCBs.

Applications of Flexible PCBs

- LED PCBs, designed with rigid boards and metal bases, lead the market.

- Improved heat resistance in materials makes flexible PCBs suitable for lightweight LED products.

- Flexible circuit boards find prominent use in automotive PCBs, offering a lighter alternative to traditional wiring.

- Breakthroughs in high polymer materials extend the stable high-temperature working range, enhancing performance in automotive applications.

Challenges and Considerations

- New materials and technologies in the PCB industry support each other, enhancing the effectiveness of flexible PCBs.

- Careful consideration of mechanical strength and deformation coefficients is crucial during the micro-hole manufacturing process for flexible PCBs.

- Estimating deformation based on through-hole manufacturing results ensures successful production of precise micropores.

As the PCB industry advances, adherence to technological innovation and independent research and development principles is essential to meet the challenges and expectations in materials, technology, and design.