Rigid-Flex PCB Design: A Comprehensive Guide

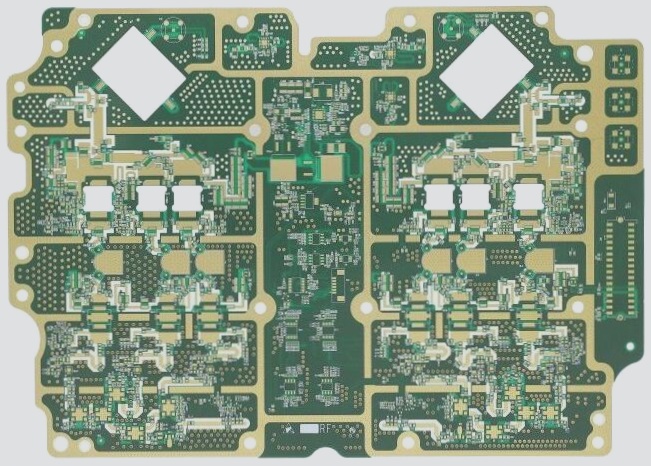

If you own a foldable, flexible, or twistable electronic device, chances are it contains a rigid-flex PCB. These innovative circuits combine the components of a standard PCB with the flexibility of a ribbon, enabling unique form factors and complex designs.

Integrated Design Software for Rigid-Flex Boards

Designing rigid-flex PCBs requires specialized software that seamlessly integrates multiple design modalities. Only with an integrated design environment can designers weave together traces, vias, and components on flexible ribbons into a cohesive and flexible circuit.

Hierarchical Schematic Design for Complex Systems

Creating complex systems with rigid-flex and multi-board designs necessitates a hierarchical schematic approach. By breaking down functional blocks into separate schematics and connecting them hierarchically, designers can effectively manage the complexity of these advanced systems.

Layer Stack Management for Efficient Production

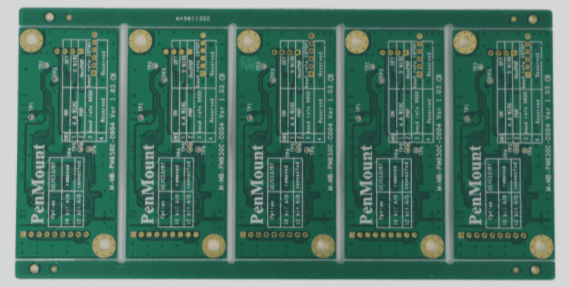

Efficient production of rigid-flex PCBs relies on user-friendly layer stack management tools. These tools help define material arrangements in rigid and flexible parts of the PCB, optimizing production costs by reducing the number of layers in specific areas.

Interactive Routing and 3D Visualization

Routing tools that facilitate easy routing across flex ribbons and component placement in flexible areas are crucial for successful rigid-flex designs. Additionally, 3D visualization tools integrated into PCB design software enable collaboration between electrical and mechanical design teams, ensuring the board’s form factor and flex capabilities are validated effectively.

Collaboration with Manufacturers for Optimal Design

Consulting with manufacturers before finalizing stackup and component placement on flex ribbons is essential for a successful design. Understanding the manufacturer’s capabilities and constraints ensures that the design aligns with production requirements.

Importing Stackup Files for Efficiency

Design software that allows the import and reuse of manufacturer-provided stackup files can save time and streamline the design process. By leveraging these files, designers can ensure that the PCB meets the manufacturer’s specifications and capabilities.