Good PCBA processing factories possess a solid understanding of the research and development involved in PCBA products. This knowledge enables them to better serve their customers and foster mutual trust. Let’s explore the development process of PCBA products.

**PCBA processing**

1. **Market research/needs analysis/project establishment**

Through market research, product managers create a demand document that outlines user pain points or industry needs, analyzes potential solutions, and clearly describes logical relationships using text or graphics. Following the requirements analysis, the project can move into the approval stage.

2. **Prototype and interaction design/APP development**

Based on the requirements document, the product manager designs the prototype, detailing the structural layout of functions, the design of each sub-page, and the business logic connecting these pages. The final output is the prototype design diagram. UI designers will then undertake the interface-related color matching, function-specific processing, interaction design, and adaptation to various models and systems, ultimately producing high-fidelity design drawings.

1. The APP engineer will develop the interface based on the high-fidelity design drawing; the server engineer will create the API interface, set up the server environment, and design the database. At a certain stage of development, the APP engineer will connect with the server, retrieve data through the server interface, and write the logic code for the functions above.

2. **Hardware Development**

Once the product project is approved, the hardware engineer must select the hardware platform based on requirements and evaluate it concerning functional needs, performance criteria, technical support, cost, and availability.

The assessment of hardware functionality and performance primarily involves selecting the main chip, requiring a specific analysis and comparison of chip resources, storage capacity and speed, I/O port allocation, and interface resources. Once the main chip is chosen, other key components will be identified based on functional diversity to achieve optimal performance and cost in the overall solution. Following the selection of the main chip, the details of the software driver layer design are largely established.

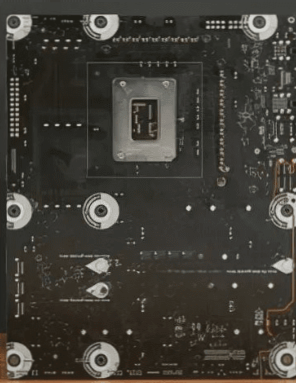

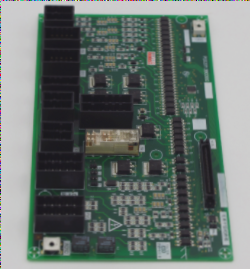

After finalizing the overall hardware plan, the development phase begins: schematic design, PCB design and production, BOM list, and PCB component placement.

3.1 **Schematic Design**

3.2 **PCB Design**

After the PCB is manufactured, 2 to 4 single boards must be sent to the software engineer for debugging, allowing the functional modules outlined in the schematic to be tested. If adjustments are needed in the principles or PCB layout after debugging, a revision of the board will be required.

The timeline and process for developing a hardware product is significantly longer than that for software, and hardware development is a technical endeavor that heavily relies on experience. Any trial and error can incur substantial costs, and only extensive experience can help avoid pitfalls. The stability of the hardware platform serves as the foundation for product reliability; only when this foundation is secure can robust software development thrive.

4. **Embedded Software Development**

The general procedure for embedded software development involves requirements analysis, software outline design, detailed software design, implementation, and testing. The main distinction from standard software development lies in the cross-compilation and cross-debugging during implementation.

Once requirements are clarified, detailed software design can commence: this includes designing the software architecture, defining functional interfaces (which encompass functionality, data structures, and global variables), and outlining the process for invoking each functional interface. After the detailed design of the software module is complete, the coding phase begins, guided by this design framework.

Once the software engineer receives the hardware PCBA board, they will utilize it for software verification and actual debugging, identifying real and theoretical issues to enhance the design.

5. **Industrial and Structural Design**

Industrial design focuses on the product’s appearance, ensuring proportionality and aesthetic appeal. Initial sketches often capture the creator’s ideas swiftly.

Once the appearance is finalized, the structural engineer will design the internal structure based on the dimensions of the PCBA board, taking into account reliability, strength, and waterproofing.

6. **Small Batch Trial Production/Public Beta/Mass Production**

During the small batch trial production phase, production engineers must monitor SMT assembly and address process issues, optimize testing procedures, and improve production yields to facilitate mass production.

Certain electronic components may exhibit abnormal parameters at specific temperatures, potentially leading to product malfunctions; some products may fail to start or power on at extremely low temperatures; others may experience changes in capacitance or resistance values at high temperatures, affecting overall product quality.

For small batches, reliability and performance testing must include functional, stress, performance, anti-interference, lifespan, and extreme temperature tests.

Following the small batch trials, some products will undergo R&D testing and reliability assessments, while others will enter public testing to face direct evaluation from users.

Upon successful verification through R&D and public testing, confirming that all processes are problem-free, the product can proceed to mass production.

7. **Quality Feedback/Big Data Analysis**

Once the product is released to the market after mass production and after a usage period (typically 3-6 months), users may provide feedback on hidden or less probable issues that testing did not reveal. R&D will conduct detailed analyses based on specific cases to identify root causes and enhance the product.

The above outlines the PCBA product development process.