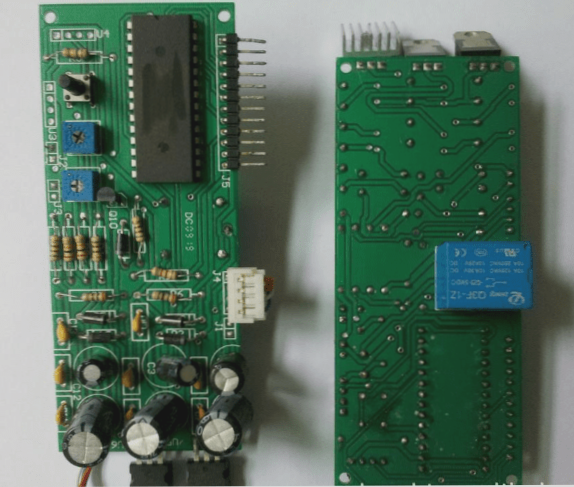

The Latest in PCB Replication Services

1. High Success Rate

Our PCB replication services boast a 100% success rate, thanks to our experienced team and efficient manufacturing design background.

2. Affordable Pricing

We prioritize sustainable partnerships and offer competitive pricing for PCB replica boards.

3. Quality Assurance

Our high-level engineers, standardized processes, and advanced equipment ensure top-notch quality assurance for all projects.

4. Professional R&D

Our skilled R&D engineers are equipped to design cutting-edge electronic products for our clients.

5. Customer Benefits

We aim to reduce costs, save time, and guarantee a 100% success rate for all PCB replication projects.

Additional Information:

- PCB Copying Services: Includes cloning, prototyping, BOM list creation, and schematic diagram export. We also offer PCB modification services.

- Forward Engineering: Providing accurate hardware circuit designs and high-quality PCB board drawings based on schematic diagrams or product descriptions.

- Wide Product Range: From household appliances to automotive electronics, we cover various industries with our PCB solutions.

- FPC Basic Knowledge: Learn about Flexible Printed Circuits (FPC) and their basic structure, including copper foil substrates, cover films, and reinforcement boards.

Trust us for all your PCB replication needs, from design to production and beyond. Contact us today for a consultation!

EMI Shielding in PCBs

- Electromagnetic shielding is crucial in PCB design to prevent interference. Top manufacturers like Topaz, Toyo, Chengbang Dali, and Fangtie offer reliable shielding films.

FPC Production Process

Double-Sided PCB Manufacturing:

- Cutting

- Drilling

- Black Hole Process

- Copper Plating

- Pre-processing

- Paste Dry Film

- Alignment

- Exposure

- Development

- Graphic Plating

- Release Film

- Pretreatment

- Paste Dry Film

- Alignment

- Exposure

- Development

- Etching

- Release

- Surface Treatment

- Applying Cover Film

- Pressing

- Curing

- Immersion in Nickel Gold

- Printing Characters

- Cutting

- Electrical Measurement

- Punching

- Final Inspection

- Packing

- Shipping

Single-Sided PCB Manufacturing:

- Cutting

- Paste Dry Film

- Alignment

- Exposure

- Development

- Graphic Plating

- Stripping

- Surface Treatment

- Cover Film Application

- Pressing

- Curing

- Immersion in Nickel and Gold

- Character Printing

- Cutting

- Electrical Testing

- Punching

- Final Inspection

- Packaging

- Shipment

Detailed PCB Process

- Cutting Material: Precisely cut copper foil to the required dimensions.

- Drilling: Create holes in the copper foil following the layout design.

- Black Hole Process: Apply a conductive film with graphite and carbon powder to hole walls, then electroplate copper.

- Immersion Nickel Gold: Nickel plating before gold plating enhances conductivity, welding, and oxidation resistance. Balancing nickel thickness is crucial for flexibility and strength.