The Rising Demand for Flexible Printed Circuits (FPCs) in Consumer Electronics

The demand for FPCs in consumer electronic devices worldwide is on the rise, with a significant portion being utilized in portable electronic gadgets like mobile phones and flat-panel TVs. The usage of FPCs in mobile phones, especially in digital camera circuits, surpasses that of rigid PCBs. In flat panel displays (FPDs), FPCs are arranged both vertically and horizontally, with their sizes expanding rapidly.

The Future of FPCs: Quality Improvements and Technological Advancements

Looking ahead, the future of FPCs not only involves an increase in quantity but also significant quality enhancements. The shift from single-sided circuits to double-sided or multilayer rigid-flex circuits is becoming more prevalent. Mass production at facilities like BOE’s Chengdu plant has propelled flexible display screens into the limelight. The vision of foldable phones and rollable devices is within reach, but challenges remain, particularly in developing flexible batteries and circuit boards.

Exploring the Technology and Trends in Flexible Printed Circuit Boards (FPCs)

In recent years, the global demand for FPCs in consumer electronics, especially in portable devices like mobile phones and flat-panel TVs, has surged. The use of FPCs in mobile phones with digital camera circuits far exceeds that of rigid PCBs. FPCs in flat panel displays (FPDs) are expanding in size and usage.

Basic Structure of FPC

The basic structure of a single-sided FPC typically involves a copper foil conductor fixed onto a base film like polyimide, sandwiched with an adhesive such as epoxy resin. To enhance properties like bend resistance, adhesive-free copper clad laminates comprising polyimide and conductor layers have been adopted.

FPC Technology Trends

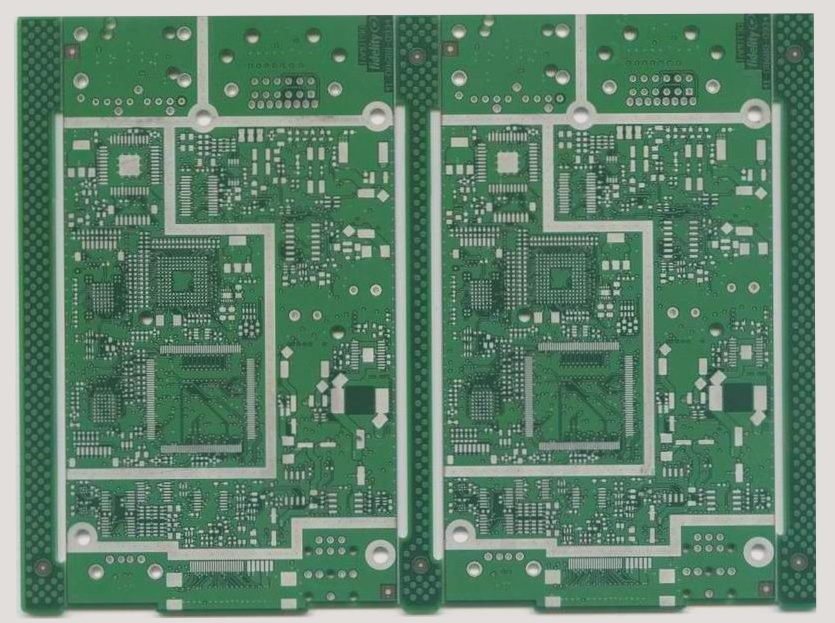

Driven by diversification and miniaturization, FPCs in electronic devices require higher circuit densities and superior performance. Recent advancements include achieving smaller conductor pitches for single-sided and double-sided circuits, made possible by technologies like CO2 lasers and chemical etching.

FPC Manufacturing Process

The Evolution of FPC Manufacturing Techniques

Traditionally, flexible printed circuit (FPC) manufacturing has predominantly utilized the subtractive method. This process involves starting with a copper-clad board and applying a resist layer using photolithography to delineate the circuit pattern. Subsequently, excess copper is etched away. However, challenges such as undercutting have restricted the method’s suitability for intricate circuits.

Enter the Semi-Additive Approach

Recognizing the limitations of the subtractive method, the semi-additive technique has emerged as a promising alternative for micro-circuit fabrication. This approach introduces various innovative methods, including coating liquid polyimide resin on a compatible substrate, sputtering to create seed layers, and electroplating to establish conductor pathways. By enabling the sequential application and removal of resist and seeding layers, this method facilitates the development of complex multilayer circuits.

Recent Advancements in FPC Manufacturing

- Advanced semi-additive techniques offer improved precision and efficiency in circuit processing.

- Integration of novel materials like liquid polyimide resin enhances circuit performance and durability.

- Automation technologies streamline the production process, reducing lead times and costs.