Industrial PCB Types Based on Rigid and Flexible:

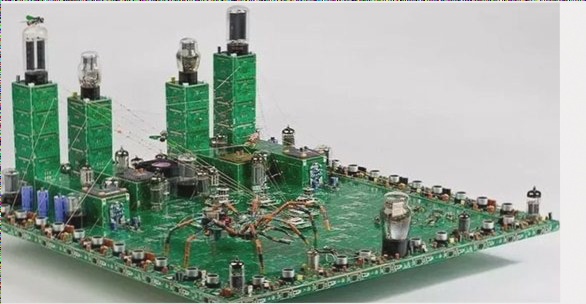

- Rigid PCBs:

- Rigid PCBs are inherently stiff and inflexible.

- They are widely used in industrial applications due to their robust nature.

- Rigid PCBs are durable, easy to repair, and handle complex designs efficiently.

- They facilitate easy implementation and organization of signal paths.

- The compact size allows for integration of complex designs for specific applications.

- All components on rigid PCBs are secured with flux for stability.

- Components remain in place even in harsh environments.

- Flexible Printed Circuit Board:

- Flexible PCBs use a flexible substrate and are inherently pliable.

- They can be bent into any desired shape during application.

- Available in single-layer, double-layer, and multi-layer formats.

- Widely used in industrial applications due to lightweight and flexibility.

- Come in various types depending on the number of layers and configurations.

- PCB with Rigid and Flexible Combinations:

- Rigid-flex PCBs combine rigid and flexible elements.

- Enhances PCB capacity and allows for flexible design options.

- Primarily used for implementing complex circuits in limited spaces.

- Commonly used in industrial applications due to rigidity and flexibility.

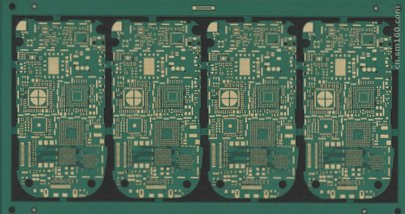

- HDI-Flex PCB:

- HDI (High-Density Interconnect) PCBs are used for high-performance applications.

- Utilize thinner layers for optimal designs and improved energy efficiency.

- Choose HDI-Flex PCBs for industrial uses requiring high performance.

- High-Frequency PCB:

- Operates at high frequencies (500MHz to 2GHz) for critical frequency applications.

- Other Types of PCBs:

- Include high-speed PCBs, LED PCBs, RF PCBs, metal-core PCBs, thick copper PCBs, gold finger PCBs, and ceramic PCBs.

For more information on PCB fabrication, visit here.

Learn about HDI PCBs here.