1. The standard for pad shape and size in PCB design is essential to the PCB package library. The minimum dimension for all pads on a single side should be no less than 0.25mm, while the maximum diameter of any pad must not exceed three times the component aperture. It is advisable to maintain a distance greater than 0.4mm between the edges of two pads. In situations with dense routing, oval and oblong connection pads are recommended. The minimum diameter or width of pads on a single-sided board is 1.6mm; for weak-current circuit pads on a double-sided board, only an additional 0.5mm should be added to the hole diameter. Excessively large pads can lead to unintended continuous soldering. Pads with apertures greater than 1.2mm or diameters exceeding 3.0mm should be designed as diamond or quincunx shapes.

2. For plug-in components, to prevent copper foil from breaking during soldering, the single-sided connection pads should be completely covered with copper foil; for double-sided boards, teardrop fills are the minimum requirement. As illustrated, all machine-inserted components must have drip pads designed in the direction of the bent leg to ensure complete solder joints. Pads situated on large areas of copper should be chrysanthemum-shaped and not soldered. If the PCB has substantial ground and power traces (covering an area greater than 500 square millimeters), a window should be partially opened or designed as a grid fill (FILL).

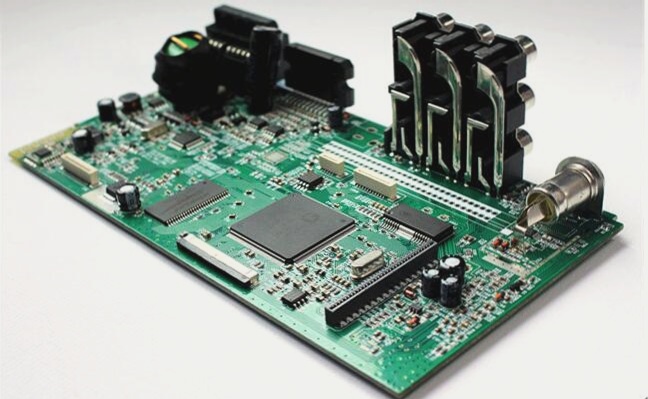

Second, the PCB manufacturing process mandates specific requirements for pads. Test points should be incorporated at both ends of chip components that are not linked to plug-in components. The diameter of these test points should be equal to or greater than 1.8mm to facilitate testing by online testers. If IC pin pads with dense pin spacing are not connected to hand-plug pads, additional test pads must be included. For SMD ICs, test points should not overlap with the SMD IC silk screen. Again, the diameter should be no less than 1.8mm for online testing purposes. When pad spacing is under 0.4mm, white oil must be applied to minimize continuous soldering during wave crest excess. Both ends of the SMD components should be designed with lead-tin. It is recommended that the lead-tin width utilize a 0.5mm wire, with a typical length of 2 to 3mm. If there are hand-soldering components on a single panel, the tin bath should be removed, oriented opposite to the soldering direction, and the hole width should range from 0.3mm to 1.0mm (50-70% of the hole diameter); as illustrated below. The spacing and size of conductive rubber buttons must align with the actual dimensions of the buttons. The PCB connected to this should be designed with a gold finger, and the corresponding gold plating thickness should be specified. The size and spacing of the pads should match that of the chip component (1:1). For solder joints where the distance between pads on the same straight line (with more than 4 pads) is less than 0.4mm, in addition to applying white oil, the long side of the component should be positioned as parallel as possible to the wave crest direction. Finally, an empty pad should be added at the end, or the pad size at the end should be enlarged to accommodate the tail solder and reduce continuous soldering.

—

Let me know if you need any further adjustments!

2. For plug-in components, to prevent copper foil from breaking during soldering, the single-sided connection pads should be completely covered with copper foil; for double-sided boards, teardrop fills are the minimum requirement. As illustrated, all machine-inserted components must have drip pads designed in the direction of the bent leg to ensure complete solder joints. Pads situated on large areas of copper should be chrysanthemum-shaped and not soldered. If the PCB has substantial ground and power traces (covering an area greater than 500 square millimeters), a window should be partially opened or designed as a grid fill (FILL).

Second, the PCB manufacturing process mandates specific requirements for pads. Test points should be incorporated at both ends of chip components that are not linked to plug-in components. The diameter of these test points should be equal to or greater than 1.8mm to facilitate testing by online testers. If IC pin pads with dense pin spacing are not connected to hand-plug pads, additional test pads must be included. For SMD ICs, test points should not overlap with the SMD IC silk screen. Again, the diameter should be no less than 1.8mm for online testing purposes. When pad spacing is under 0.4mm, white oil must be applied to minimize continuous soldering during wave crest excess. Both ends of the SMD components should be designed with lead-tin. It is recommended that the lead-tin width utilize a 0.5mm wire, with a typical length of 2 to 3mm. If there are hand-soldering components on a single panel, the tin bath should be removed, oriented opposite to the soldering direction, and the hole width should range from 0.3mm to 1.0mm (50-70% of the hole diameter); as illustrated below. The spacing and size of conductive rubber buttons must align with the actual dimensions of the buttons. The PCB connected to this should be designed with a gold finger, and the corresponding gold plating thickness should be specified. The size and spacing of the pads should match that of the chip component (1:1). For solder joints where the distance between pads on the same straight line (with more than 4 pads) is less than 0.4mm, in addition to applying white oil, the long side of the component should be positioned as parallel as possible to the wave crest direction. Finally, an empty pad should be added at the end, or the pad size at the end should be enlarged to accommodate the tail solder and reduce continuous soldering.

—

Let me know if you need any further adjustments!