The emergence of tablet computers has instigated a significant transformation in global computing technology. Their inherent portability, ultra-slim profile, and multifunctional capabilities impose substantial demands on backup power solutions. Polymer lithium batteries differ from traditional cylindrical lithium batteries and have emerged as the preferred choice for high-end consumer electronics, thanks to their superior space utilization, customizable sizes, ultra-thin designs, enhanced safety, and exceptional reliability. As the evolution of tablet PCs accelerates, the associated PCB requirements are also on the rise. Let’s explore the PCB design strategies tailored for tablet computers.

1. Design requirements for the tablet PC PCB smart battery solution: Based on customer specifications, the design of the tablet’s smart battery pack must align with the host computer. This includes integrating a smart fuel gauge with the SBS communication protocol and ensuring battery safety features are included. This integration will facilitate information sharing between the battery pack and the host, ultimately creating an efficient, safe, and well-managed battery program. The design must ensure that the finished batteries exhibit ultra-thinness, high capacity, extended cycle life, enhanced safety, and consistent performance.

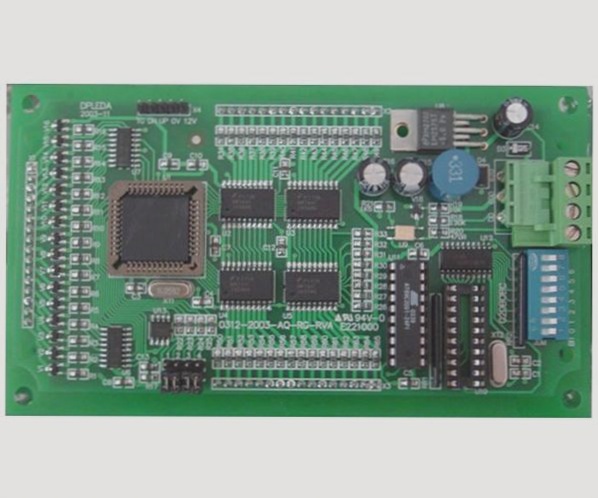

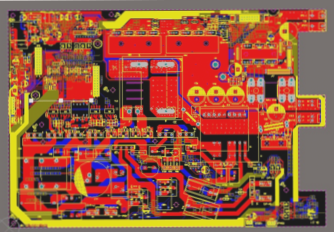

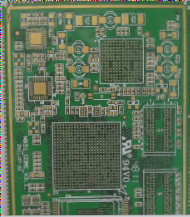

2. Specific design parameter requirements for the tablet PC PCB smart battery: 1) Cell selection: Utilize top-tier domestic polymer cells (PL5159115-2S1P/3.8Ah/3.7V). 2) Appearance PCB design: The product will be encased in PET synthetic paper, presenting a classic and elegant look. 3) PCB design requirements: A precise power management circuit alongside a secondary overvoltage protection circuit is essential. The design employs an SBS intelligent battery management system to continuously manage the battery’s remaining power.

3. Tablet PC PCB smart battery solution design scheme: 1) 9PIN output connection terminal: The MIN connection terminal’s wiring must meet the customer’s output current specifications, including connections for 3/P+, NTC, SMBC, SMBD, and 3/P-, among others. 2) Smart fuel gauge protection for the tablet motherboard (PCM): The SBS smart battery management system will utilize advanced power calculation principles to monitor battery power in real-time, communicating this data via SMBUS. It will also provide essential protective features for rechargeable lithium battery packs, addressing overcharge, overdischarge, short circuits, overcurrent, and overtemperature risks to prevent hazards like fires or explosions. 3) Panel light computer PCB temperature protection device (one-time): The secondary overvoltage protection will primarily monitor the battery cell voltage; if a single cell exceeds 4.45V, the temperature protection device will activate through peripheral circuits to disconnect the loop, safeguarding the battery pack from overvoltage. 4) Overcurrent protection sheet (BREAKER recoverable): This protection features overcurrent and temperature detection. It activates when the current reaches 12A or the temperature hits 75°C, resuming normal function once the temperature drops. 5) PL5159115/3.8Ah/7.4V polymer lithium battery (ATL): This battery boasts large capacity, ultra-thin design, high safety, and consistency. In response to the rising demands for tablet PC PCBs, the PCB design has implemented effective solutions to meet all customer requirements for tablet PC PCB specifications.

1. Design requirements for the tablet PC PCB smart battery solution: Based on customer specifications, the design of the tablet’s smart battery pack must align with the host computer. This includes integrating a smart fuel gauge with the SBS communication protocol and ensuring battery safety features are included. This integration will facilitate information sharing between the battery pack and the host, ultimately creating an efficient, safe, and well-managed battery program. The design must ensure that the finished batteries exhibit ultra-thinness, high capacity, extended cycle life, enhanced safety, and consistent performance.

2. Specific design parameter requirements for the tablet PC PCB smart battery: 1) Cell selection: Utilize top-tier domestic polymer cells (PL5159115-2S1P/3.8Ah/3.7V). 2) Appearance PCB design: The product will be encased in PET synthetic paper, presenting a classic and elegant look. 3) PCB design requirements: A precise power management circuit alongside a secondary overvoltage protection circuit is essential. The design employs an SBS intelligent battery management system to continuously manage the battery’s remaining power.

3. Tablet PC PCB smart battery solution design scheme: 1) 9PIN output connection terminal: The MIN connection terminal’s wiring must meet the customer’s output current specifications, including connections for 3/P+, NTC, SMBC, SMBD, and 3/P-, among others. 2) Smart fuel gauge protection for the tablet motherboard (PCM): The SBS smart battery management system will utilize advanced power calculation principles to monitor battery power in real-time, communicating this data via SMBUS. It will also provide essential protective features for rechargeable lithium battery packs, addressing overcharge, overdischarge, short circuits, overcurrent, and overtemperature risks to prevent hazards like fires or explosions. 3) Panel light computer PCB temperature protection device (one-time): The secondary overvoltage protection will primarily monitor the battery cell voltage; if a single cell exceeds 4.45V, the temperature protection device will activate through peripheral circuits to disconnect the loop, safeguarding the battery pack from overvoltage. 4) Overcurrent protection sheet (BREAKER recoverable): This protection features overcurrent and temperature detection. It activates when the current reaches 12A or the temperature hits 75°C, resuming normal function once the temperature drops. 5) PL5159115/3.8Ah/7.4V polymer lithium battery (ATL): This battery boasts large capacity, ultra-thin design, high safety, and consistency. In response to the rising demands for tablet PC PCBs, the PCB design has implemented effective solutions to meet all customer requirements for tablet PC PCB specifications.