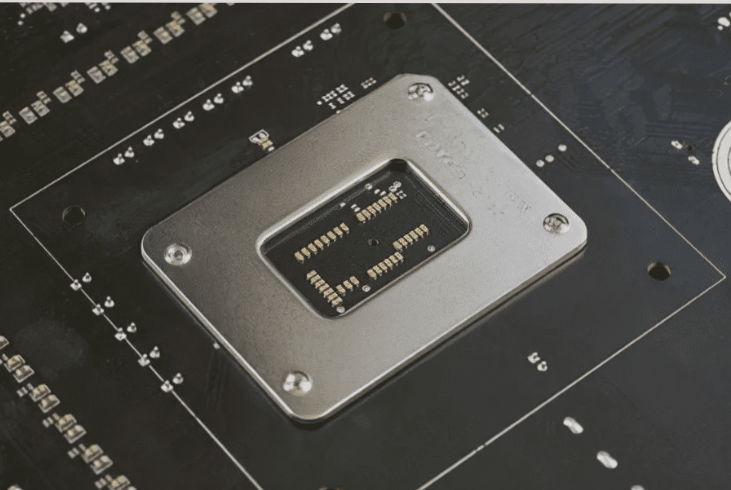

PCB Additive Process

In the age of the Internet, traditional marketing models have been disrupted, leading to more efficient aggregation of resources through online platforms. This transformation has accelerated the advancement of FPC (Flexible Printed Circuit) boards. However, with this rapid development comes increasing environmental challenges for PCB manufacturers. Despite this, the Internet’s rise has also driven progress in environmental protection and sustainability, particularly in environmental data management and green electronic procurement, which are being integrated into production processes. The additive method involves selectively depositing conductive metal onto an insulating substrate to create a conductive pattern.

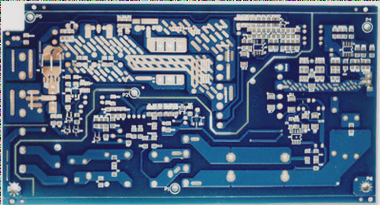

Advantages of the Additive Method

- The additive process reduces production costs significantly by eliminating much of the copper etching, thus lowering manufacturing expenses.

- Compared to the subtractive process, the additive method reduces production time by about one-third, enhancing overall efficiency.

- This process enables the production of high-precision printed boards with smooth, flush wires and surfaces, suitable for applications like SMT (Surface Mount Technology).

- Uniform copper plating thickness across the hole wall and board surface improves the reliability of metallized holes, meeting the requirements for high aspect ratio PCBs and copper plating in small holes.

Classification of Additive Methods

- Full Additive Process: Relies solely on electroless copper to form conductive patterns, such as the CC-4 method.

- Semi-additive Process: Metal is chemically deposited onto the insulating substrate, combined with electroplating and etching to form conductive patterns.

- Partial Additive Process: Uses the additive method on catalytic copper-clad laminates to manufacture printed boards.

Our factory in Shenzhen, China, has been a key player in the global electronics R&D and manufacturing scene for years. Approved by the Chinese government, we offer direct product purchases on our website without intermediaries. This direct factory approach is why 100% of our repeat customers choose WellCircuits. If you have any PCB manufacturing needs, feel free to contact us.