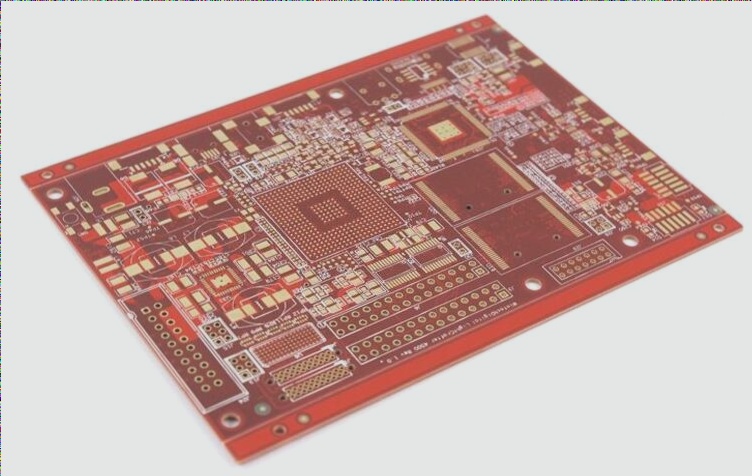

PCBA Aging Test: Ensuring Reliability and Stability

PCBA Aging Test evaluates and verifies the reliability of PCBAs under prolonged use and environmental changes. It simulates real-world aging scenarios to ensure stable performance over time.

Designing the Aging Test Program

- Determine parameters based on PCBA design and usage environment.

- Consider factors like aging time, temperature, humidity, and voltage.

- Refer to industry standards for guidance.

Setting Up Test Equipment

- Prepare aging equipment like boxes and regulators.

- Adjust parameters such as temperature and voltage.

Conducting the Aging Test

- Place the PCBA in the aging equipment securely.

- Expose it to the specified conditions.

- Monitor electrical parameters during the test.

Verifying Test Results

- Perform functional and performance tests post-aging.

- Check modules, interfaces, and ports for reliability.

Recording and Reporting

- Document test results for quality control.

- Use reports for traceability and future improvements.

PCBA Aging Test is essential for ensuring long-term stability and reliability. It helps in detecting potential issues early and making necessary improvements.