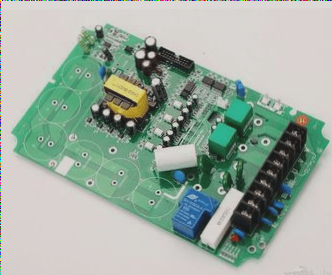

1. PCB alkaline etching is a crucial technique for removing unwanted materials from the surface during the PCB manufacturing process.

2. Etching plays a critical role in removing excess copper from the copper layer, thereby leaving the required circuit intact.

3. There are two primary types of PCB etching techniques: wet etching and dry etching.

In general, the acidic etching solution is more suitable for the inner layer, while the alkaline etching solution is more suitable for the outer layer of the circuit board. After etching, only the tin remains on the circuit board, and the board will enter the tin removal process as the roller moves. Here, a chemical solution will be used to dissolve the tin layer on the circuit board, restoring the original color of copper to the circuit board.

The principle of circuit board alkaline etching

The principle of circuit board etching is to use chemical reactions to remove metal materials from the circuit board. A layer of photosensitive adhesive is applied to the circuit board, and then the circuit pattern is transferred onto the photosensitive adhesive through photolithography technology. The circuit pattern formed on the photosensitive adhesive will block the action of the alkaline etching solution so that the etching solution can only etch metal materials outside of the circuit pattern. An etching solution is usually a strong acid or base that can chemically react with metal materials to etch them away.

Method of alkaline etching circuit boards

PCB alkaline etching is a technique for removing unwanted materials from the surface. As part of the PCB manufacturing process, etching removes excess copper from the copper layer, leaving the required circuit on it. There are two types of PCB alkaline etching techniques: wet etching and dry etching.

Wet etching

Wet etching refers to chemical etching, which uses two chemicals: acidic chemicals and alkaline chemicals.

1) Acid etching

In the acidic PCB etching process, the etchants used are iron chloride (FeCl3) and copper chloride (CuCl2). Acid etching is commonly used for inner layer etching in rigid PCBs. The reason is that acidic etching is more accurate and cheaper than alkaline etching. Acid solvents do not react with photoresist and will not damage the required components. In addition, this method has the minimum undercut, which is the copper portion removed below the photoresist. However, acidic etching is more time-consuming than alkaline etching.

2) Alkaline etching

Alkaline etching is the chemical removal of unwanted copper layers from circuit patterns under alkaline conditions. Alkaline etching is suitable for etching outer circuit patterns such as lead/tin plating, nickel plating, gold plating, etc. The alkaline etchant is a combination of copper chloride and ammonia.

Dry etching

Dry PCB etching uses gas or plasma as an etchant to remove unnecessary substrate materials. Unlike wet etching, dry etching avoids the use of chemicals and generates a large amount of hazardous chemical waste. At the same time, it reduces the risk of water pollution.

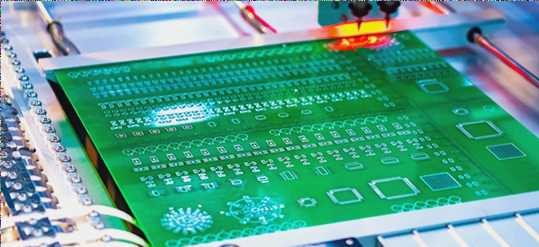

Laser etching

Laser etching is one of the dry etching methods that utilizes computer-controlled hardware to produce high-quality PCBs. The wiring on the PCB substrate is carved from high-power materials contained in the laser beam. Then, the computer etches out the unwanted copper traces. Compared with other wet PCB etching technologies, laser etching greatly reduces the number of steps, thereby reducing production costs and time.

Plasma etching

Plasma etching is another dry etching technology aimed at reducing liquid waste treatment in the manufacturing process and achieving selectivity that is difficult to obtain in wet chemistry. It is a selective etching that reacts with chemically active radicals. It also includes guiding the high-speed plasma flow of the appropriate gas mixture to the etched material. Compared to wet etching methods, plasma etching is clean. In addition, it can simplify the entire process and improve dimensional tolerances. Plasma PCB etching can be controlled and accurately etched within a very small range. This special process also reduces the occurrence of contamination via pores and solvent absorption.

PCB alkaline etching mainly includes acidic and alkaline etching, and its main purpose is to use chemical strong acids or bases to react with the copper surface of the PCB board, etching off non-circuit bottom copper. The copper layer below the position with dry film or electrical protection tin is retained, and by controlling the concentration of etching line solution, temperature, etching speed, nozzle pressure, etc., to achieve the line width/line spacing, IC/solder pad/BGA, etc. required by customer drawings.

For more information, click the website: wellcircuits.com

To enhance Your Business Efficiency, contact us:

To discover How Our Solutions Can Help Your Business, contact us:

Stay Ahead in Your Industry – Subscribe to Our Latest News

Customized Solutions Await Discovery – Contact Our Sales Team

Don’t Miss Critical Updates – Subscribe to us now

2. Etching plays a critical role in removing excess copper from the copper layer, thereby leaving the required circuit intact.

3. There are two primary types of PCB etching techniques: wet etching and dry etching.

In general, the acidic etching solution is more suitable for the inner layer, while the alkaline etching solution is more suitable for the outer layer of the circuit board. After etching, only the tin remains on the circuit board, and the board will enter the tin removal process as the roller moves. Here, a chemical solution will be used to dissolve the tin layer on the circuit board, restoring the original color of copper to the circuit board.

The principle of circuit board alkaline etching

The principle of circuit board etching is to use chemical reactions to remove metal materials from the circuit board. A layer of photosensitive adhesive is applied to the circuit board, and then the circuit pattern is transferred onto the photosensitive adhesive through photolithography technology. The circuit pattern formed on the photosensitive adhesive will block the action of the alkaline etching solution so that the etching solution can only etch metal materials outside of the circuit pattern. An etching solution is usually a strong acid or base that can chemically react with metal materials to etch them away.

Method of alkaline etching circuit boards

PCB alkaline etching is a technique for removing unwanted materials from the surface. As part of the PCB manufacturing process, etching removes excess copper from the copper layer, leaving the required circuit on it. There are two types of PCB alkaline etching techniques: wet etching and dry etching.

Wet etching

Wet etching refers to chemical etching, which uses two chemicals: acidic chemicals and alkaline chemicals.

1) Acid etching

In the acidic PCB etching process, the etchants used are iron chloride (FeCl3) and copper chloride (CuCl2). Acid etching is commonly used for inner layer etching in rigid PCBs. The reason is that acidic etching is more accurate and cheaper than alkaline etching. Acid solvents do not react with photoresist and will not damage the required components. In addition, this method has the minimum undercut, which is the copper portion removed below the photoresist. However, acidic etching is more time-consuming than alkaline etching.

2) Alkaline etching

Alkaline etching is the chemical removal of unwanted copper layers from circuit patterns under alkaline conditions. Alkaline etching is suitable for etching outer circuit patterns such as lead/tin plating, nickel plating, gold plating, etc. The alkaline etchant is a combination of copper chloride and ammonia.

Dry etching

Dry PCB etching uses gas or plasma as an etchant to remove unnecessary substrate materials. Unlike wet etching, dry etching avoids the use of chemicals and generates a large amount of hazardous chemical waste. At the same time, it reduces the risk of water pollution.

Laser etching

Laser etching is one of the dry etching methods that utilizes computer-controlled hardware to produce high-quality PCBs. The wiring on the PCB substrate is carved from high-power materials contained in the laser beam. Then, the computer etches out the unwanted copper traces. Compared with other wet PCB etching technologies, laser etching greatly reduces the number of steps, thereby reducing production costs and time.

Plasma etching

Plasma etching is another dry etching technology aimed at reducing liquid waste treatment in the manufacturing process and achieving selectivity that is difficult to obtain in wet chemistry. It is a selective etching that reacts with chemically active radicals. It also includes guiding the high-speed plasma flow of the appropriate gas mixture to the etched material. Compared to wet etching methods, plasma etching is clean. In addition, it can simplify the entire process and improve dimensional tolerances. Plasma PCB etching can be controlled and accurately etched within a very small range. This special process also reduces the occurrence of contamination via pores and solvent absorption.

PCB alkaline etching mainly includes acidic and alkaline etching, and its main purpose is to use chemical strong acids or bases to react with the copper surface of the PCB board, etching off non-circuit bottom copper. The copper layer below the position with dry film or electrical protection tin is retained, and by controlling the concentration of etching line solution, temperature, etching speed, nozzle pressure, etc., to achieve the line width/line spacing, IC/solder pad/BGA, etc. required by customer drawings.

For more information, click the website: wellcircuits.com

To enhance Your Business Efficiency, contact us:

To discover How Our Solutions Can Help Your Business, contact us:

Stay Ahead in Your Industry – Subscribe to Our Latest News

Customized Solutions Await Discovery – Contact Our Sales Team

Don’t Miss Critical Updates – Subscribe to us now