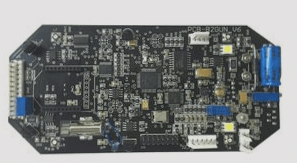

PCBA (Printed Circuit Board Assembly) refers to the process of assembling electronic components onto a PCB. This process can only be considered complete after all assembly processes have been carried out. PCBA involves both surface-mount technology (SMT) and through-hole technology (THT), which includes solder paste printing, pick-and-place assembly, reflow soldering, wave soldering, testing, and quality inspection.

The PCBA process flow chart can vary depending on factors such as the type of PCB board, production technology, and complexity of the design. Here are some common types of PCBA production flows:

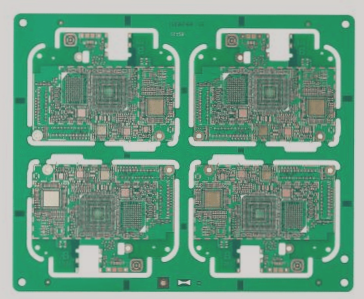

PCB is an abbreviation for printed circuit board and an indispensable component in electronic products.

The design and manufacturing of PCBs require professional knowledge and technology, thus requiring experienced experts to be responsible.

In the production process of PCB, it is necessary to ensure that every detail is rigorously reviewed and tested.

1. 原文:PCB是印刷电路板的缩写,是电子产品中必不可少的元件之一。

1. 原文:PCB是印刷电路板的缩写,是电子产品中必不可少的元件之一。

When seeking PCBA assembly and processing manufacturers, it is crucial to choose experienced providers with high levels of processing equipment. The quality of solder joints on electronic components determines the overall quality of the PCBA board. Therefore, manufacturers should prioritize ensuring that their assembly process and production processes are optimized in order to consistently produce high-quality finished products.