Printed Circuit Board Assembly: The Key to High-Quality Electronic Products

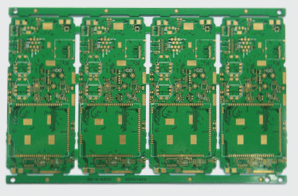

Printed circuit board assembly, known as PCBA, is a vital manufacturing process for creating electronic products that consumers rely on and enjoy. While original equipment manufacturers traditionally handled PCB assembly in-house, the rise of surface mount technology has led to a shift towards outsourcing to specialized contract electronics manufacturers.

Outsourcing PCB Assembly for Cost-Effective Solutions

For PCB suppliers considering internal assembly, the expenses can be significant. Setting up manufacturing facilities, production lines, purchasing equipment, and providing staff training all contribute to high costs and a lengthy return on investment. Opting to work with a professional assembly company offers a more financially feasible solution. Outsourcing PCB assembly can lead to cost savings on capital expenditures, ultimately reducing the cost per device and enhancing market competitiveness for OEMs.

Enhancing Design Services for Improved PCBs

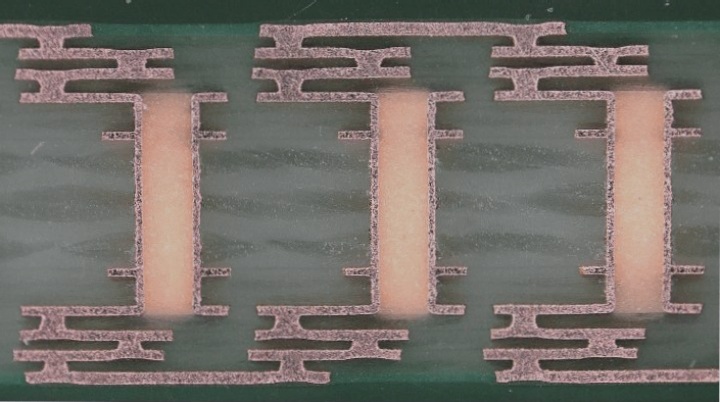

Integrating assembly costs into electronic design services can result in design enhancements for printed circuit boards. PCB suppliers that offer design services focus on ensuring that electronic designs optimize the PCB, leading to higher-quality products at a reduced cost. Many established companies specialize in mass-producing printed circuit boards and PCB components, delivering projects efficiently while meeting strict deadlines.

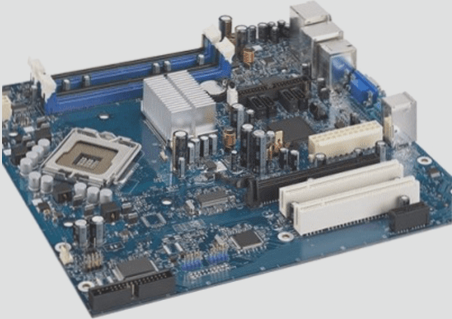

Ensuring High Quality in a Competitive Market

In today’s competitive landscape, maintaining high quality is paramount. Comprehensive quality assurance processes are essential for producing top-notch products and ensuring customer satisfaction. Consumer electronics manufacturers adhere to stringent quality systems and utilize testing equipment to validate PCB quality. Professional PCB manufacturers also implement robust quality systems and processes, leveraging industry relationships to access premium electronic assembly and engineering services.