Do you know about the PCB assembly services, and why do you need them? Well, it’s a complex phenomenon that one might feel difficult to understand, but we will break it down for you. If you want to know about the PCN assembly services for telecom companies, you need to know about the basics of PCB and how it is assembled. Only then can you have the confidence to choose those services that are efficient for you. Therefore, our article will navigate you through the basics of PCB and help you reach that point where you can distinguish between the services that you would require or not assemble the PCB. Keep reading this article till the end.

Let’s begin with the basics of PCB assembly.

What is PCB assembly?

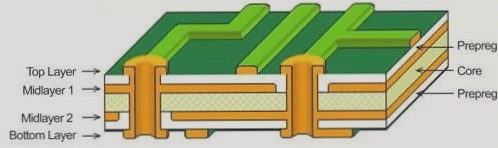

Printed circuit board assembly is one of the main strides in PCB creation that includes every one of the parts that are expected to make up the total PCB. There are 2 strategies to build a printed circuit board gathering; specifically, Surface Mount Technique (SMT) and Through-Hole Technique (THT). SMT is useful where there is restricted space, and THT gives solidarity to the parts. Therefore, in simple words, the PCB assembly requires the assembling of essential components to create a whole PCB. Moreover, Printed Circuit Board assembly is one of the backbones of buyer hardware today, albeit that is just the situation for the last 30-40 years. Because of the improvement of surface mount innovation and other progressed production strategies, it’s presently become more straightforward for most organizations to outsource their jobs to a PCB assembly assistance than to do it in-house. This was all you needed to know about the basics of PCB assembly.

What’s the process of assembling a PCB?

There are different strategies to assemble a PCB. And each strategy requires multiple steps. In this article, as we are dealing with basic level information, our main goal is to provide that information that you can easily digest. Therefore, we have crafted some steps by which a PCB is assembled.

- Use of stencil to apply solder paste:

A solder paste consists of about 96.5% tin and contains 3% of silver and 0.5% of copper. It is to be noted that this solder paste is preferred because it doesn’t have lead in it. Lead can be injurious to the ecosystem. This paste is then applied to the areas of the PCB board where we have to fit the components. It is done by applying this paste of a stencil which is held together with PCB by the mechanical fixture. Afterward, by the use of an applicator, the solder paste is spread uniformly over the board.

- The placements of the components on the board:

In the second step, the pick and place robot is used for the automated placement of SMT components on your PCB board. The robot work according to a file generated by the designer, and this file is based upon the coordinate system so that the robot can easily place the SMD devices on the board. It is to be noted that the robot places the components over the soldered place.

- Integration of components in the solder paste:

As the third step is already self-explanatory, the components are been set in the solder paste on this level. Therefore, the components with the PCBs are placed in the conveyer belt. In this conveyer belt, the PCBs face a temperature of about 250 to 260 degrees Celsius. Under this high temperature, the solder pastes that we used in the first step melt. Consequently, the grip of this melted paste automatically increases on the components. And it will create a strong joint between SMT and PCB.

- Check for the short circuit:

After the PCBs are done passing through high temperatures, there are chances that this temperature might have caused damage to the components of PCBs. Therefore, inspection is done by some strategies like manual inspection and optical inspection to ensure that there isn’t any short or open circuit. As mentioned, there are two types of inspections that a PCB board needs to go through to attain the surety of the developers. The manual inspections involve a visual go-through of the PCB by the technician. But most of the time, it ends up giving inaccurate results. Therefore, optical inspection is always preferred. This method uses the types of machinery with high-powered and high-resolution cameras integrated into them at various angles to view the PCB from various angles. This procedure is extremely efficient and fast.

- Fixing the THT component:

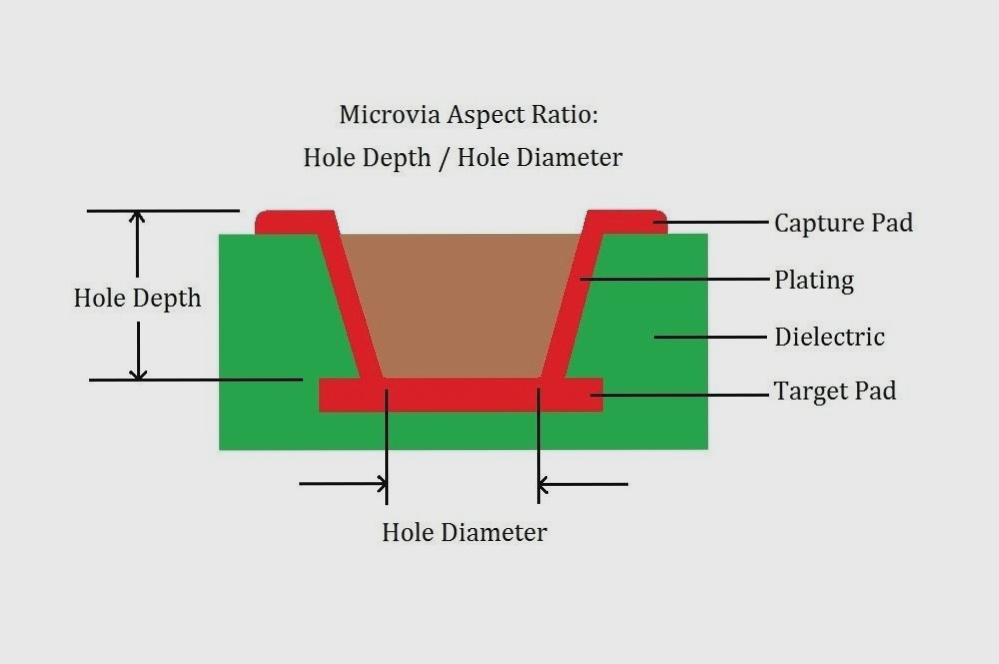

The THT parts are generally found on numerous PCB sheets. These parts are also called Plated through holes (PTH). These parts have driven that will go through the opening in the PCB. These openings interface with different openings and vias through copper traces. At the point when these THT parts are embedded and bound in these openings, then they are electrically associated with another opening in a similar PCB as the circuit planned. These PCBs might contain a few THT parts and numerous SMD parts, so reflow soldering will not work on THT components. Therefore, there are two types to deal with the situation; Manual and Wave soldering. Manual soldering is not favored due to its inaccurate results; therefore, the wave soldering here is the automated one.

- The final stage:

This is the last stage for the assembling of a PCB. Tests have been run on a PCB to make sure that it is running fine. For this purpose, electrical signals have been sent to the PCB, and the output is checked. If the PCB is unable to provide you with the desired outcome, it is discarded from the stack. After a PCB passes the test, the unwanted flux has been cleansed from the PCB. The oil stains are removed by the use of a stainless steel-based high-pressure washing which uses deionized water for cleansing purposes. Afterward, the PCB is dried using compressed air. And that’s how a PCB is manufactured.

Why do we need the PCB assembly services?

As we can see, this manufacturing process is highly précised and complex. Therefore, you require PCB assembly services, especially for telecom companies. Even if we ignore the complexity of this process, there are multiple other reasons and benefits to getting the PCB assembly services for telecom companies. Let’s have a look at them.

- Saving on ventures and work costs

Benefiting from PCB gathering assembly from outside firms saves the organizations a seriously enormous measure of ventures and work costs. Plenty of costs is engaged with PCB assembly that incorporate exercises like setting up tasks, employing work, overseeing stock, keeping up with and overhauling their office, etc. On rethinking the PCB assembly administrations, this multitude of undertakings is dealt with remotely.

- Profiting from professional assistance

By employing an outside and master PCB assembly house, organizations can have the confidence of finishing the best PCB congregations and thus benefit from specific abilities. This PCB assembly assistance gives organizations have a specialist work-power to offer exact, able, and great PCB assembly in adherence to the most recent industry norms.

- Focus on center capabilities

By rethinking the PCB assembly administrations from outside specialist co-ops, organizations can focus on their center capabilities and essential item improvements. As the PCB assembly administrations are dealt with by the outside firms, organizations can focus on other significant exercises like brand constructing, investigating and reinforcing its deals, and showcasing network.

- Improved Efficiency

A PCB Assembly administration that offers the capacity to deal with a higher number of units and cluster creation in one go. You can save energy and time and stay away from asset wastage by utilizing PCB Assembly administration for your creation. Additionally, the cash and time in this manner saved can be more productively utilized and channelized towards working on the general nature of the item. Additionally, when the proficiency improves, the pace of creation increments, too, yielding a far larger number of units at a similar expense and with a similar exertion.

- Productivity

Incorporating a Printed Circuit Board is perhaps the simplest approach to work on the pace of efficiency even inside restricted implies. This sort of answer is an optimal entryway for humble producers to effectively assume responsibility and convey a moderately bigger number of requests without placing an enormous strain on the current apparatus. Likewise, numerous multiple times, they could need house skill in making Printed Circuit Board, and for such events, these PCB Assembly benefits are not just helpful choices to support creation yet in addition very exceptional yield speculation for the organizations picking them.

Conclusion:

As we have gone through the benefits and process of PCB assembly, you might want to know where you can get these exceptional services. If that’s the case, we have just the right gift for you. We have been providing these services for a while now, and we have served many satisfied customers with our unmatched services. If you want to enjoy our services for these assembling purposes, you can reach out to us. We take précised measures to ensure that you get the best quality stock that has minimal to no damaged PCB. Click here to get redirected to our page, where you can know more about our services and contact us to arrange your first appointment. We are looking forward to working with you.