**Four PCB Splitters Capable of Dividing Various-Shaped PCB Boards**

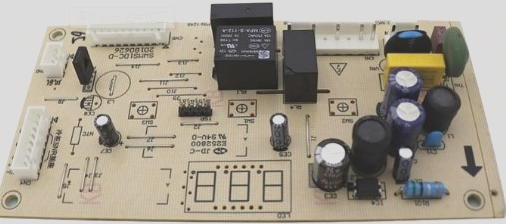

The commonly used PCB splitter model for irregular-shaped PCB boards is designed for specific applications. As the name suggests, irregular-shaped PCBs are those whose splicing methods are not linear, employing various unconventional connection techniques. This splicing approach provides greater flexibility in the design and production of modern products compared to the traditional V-groove method. The use of special-shaped PCB splicing boards is increasingly gaining traction. Currently, four models of special-shaped PCB splitting machines have been developed and produced. The following introduces these four types of PCB splitters for irregular-shaped boards.

1. **Pneumatic Punching PCB Splitter, CWPE**: To utilize this model, you need to create a set of custom hardware punching dies tailored to the specific arrangement of the irregular-shaped PCB. Once prepared, these dies can be installed on the pneumatic punching PCB splitter to execute the cutting operation. This machine can cut an entire special-shaped PCB board in a single pass and is capable of dividing both flexible and rigid boards. This model features a movable caster design for ease of operation.

To operate, install the splitting die on the pneumatic punching PCB splitter, position the irregular-shaped PCB on the corresponding spot of the lower mold, and press the start switch for a one-time split. The lower mold employs an automatic push and pull mechanism during operation to minimize labor intensity. This ensures a more efficient process and facilitates easy handling of the finished products.

**Pneumatic Punching Type PCB Splitter**

The pneumatic punching type PCB splitter is utilized for batch die-cutting of circuit boards in mobile phones, digital cameras, electronic accessories, computers, automobiles, and more. It is particularly effective for cutting multi-connected circuit boards. The electronics industry encompasses mobile phone boards, memory cards, mobile phone flexible circuits, HDI (High Density Interconnector) PCBs, FPCBs (Flexible Printed Circuit Boards), and FCCLs (Flexible Copper Clad Laminates). Its efficiency is especially notable when segmenting large quantities of through-slot PCB substrates and flexible circuit boards (FPCs).

**Features of Pneumatic Punching PCB Splitter, CWPE:**

1. High degree of automation with simple and safe operation.

2. Interchangeable molds that are easy to change.

3. Automatic lower mold in-and-out function, facilitating product handling, with finished products stored in a drawer.

4. Reduces internal stress during board cutting, helping to avoid tin cracking.

5. Extremely high efficiency for punching semi-finished PCBs and FPCs.

**Institutional Stamping Type PCB Splitter, CWPL:**

To use this model, a set of hardware punching dies must be created based on the specific PCB layout, which is then installed onto the institutional stamping type PCB splitter for cutting operations. A full-page special-shaped PCB can be cut in one go, accommodating both flexible and rigid boards. This model functions as a desktop splitting machine.

The working principle mirrors that of the CWPE, with the primary difference being the power source for the punching die: one uses pneumatic power while the other employs mechanical movement. Additionally, one is desktop-mounted while the other is designed for portability. Selection can be based on the factory conditions and production line requirements.

**Pneumatic Hook Knife Type PCB Splitter, CWV-LT:**

This model facilitates punching with “T” or “L” hook knife blades for slitting, ideal for customers needing to cut special-shaped PCB models and quantities. This method is economically efficient.

**Features of Pneumatic Hook-Knife PCB Splitter, CWV-LT:**

1. Fully pneumatic control ensures simple operation.

2. Suitable for cutting various PCB connection points.

3. Customizable hook knife shapes.

4. Quick and convenient hook knife replacement.

5. Compact design that prevents damage to the substrate and components.

**Milling Cutter Type PCB Splitter, Visual Automatic PCB Splitter, CW-F01:**

This model offers a higher degree of automation and is generally more cost-effective for customers with large volumes of special-shaped PCBs.

The milling cutter type PCB splitter primarily utilizes high-speed milling to divide multiple rigid PCBs along a pre-programmed path, overcoming the limitation of traditional splitters that can only cut in straight lines. Using this milling cutter splitter ensures smooth cutting surfaces and product safety. The operational stress is minimal, which reduces the risk of damage to small components like BGAs and QFPs. Its flexibility allows it to be suitable for irregular rigid PCB segmentation with stamp hole connections.

**Basic Information on PCB Board Automatic Locking Screw Machine:**

1. Products are prone to damage.

2. Requires numerous employees, leading to high daily operating costs and management challenges.

3. High output may exceed production requirements.

The automatic locking screw machine is specifically designed for securing products. It typically employs manual feeding and controls for starting and stopping the screw machine, making it ideal for larger items. Multi-axis locking machines often need a base mold to secure products, necessitating custom molds due to variations in size and shape.

**Key Features:**

1. The number of locking shafts can range from 1 to 16, enabling simultaneous driving of multiple screws.

2. Capable of locking multiple screws of the same or different specifications on identical workpieces, enhancing efficiency for mechanized and high-automation production lines.

3. All-in-one design allows for flexible integration of various peripheral auxiliary operations.

4. Intelligent detection ensures no missed locks or sliding teeth during the locking process, minimizing inspection needs.

5. Good versatility, allowing manual settings for specific electric screwdrivers without locking screws.

If you have any PCB manufacturing needs, please do not hesitate to contact me.Contact me