1. **Comparison of Advantages and Disadvantages of PCB Circuit Board Baking**

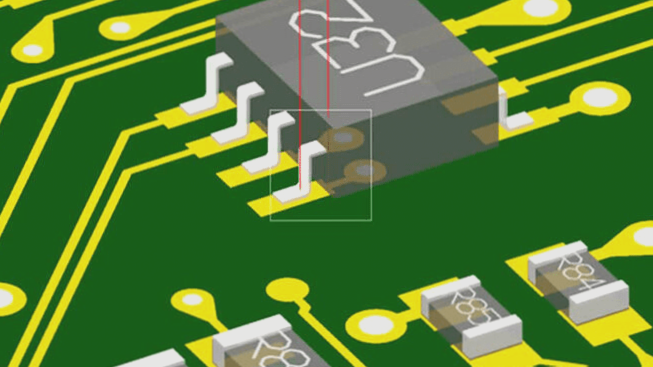

2. PCB circuit board baking can alleviate internal stress, stabilizing the PCB’s dimensions and reducing warpage.

3. **Advantages of Baking:** Baking dries the moisture in the pad, enhancing the soldering effect and reducing false soldering and repair rates.

4. **Disadvantages of Baking:** Baking may alter the color of the PCB, impacting its appearance.

5. The OSP process typically has a 6-month shelf life after packaging. If this period is exceeded, the board generally needs to be returned to the PCB manufacturer for rework.

6. Baking usually occurs at 100-120°C for about 2 hours—avoid overbaking! Boards should be used within 24 hours of exposure to air to prevent oxidation (this depends on the supplier’s capability; some OSPs can last longer, but it’s best to use them within 8 hours of unpacking).

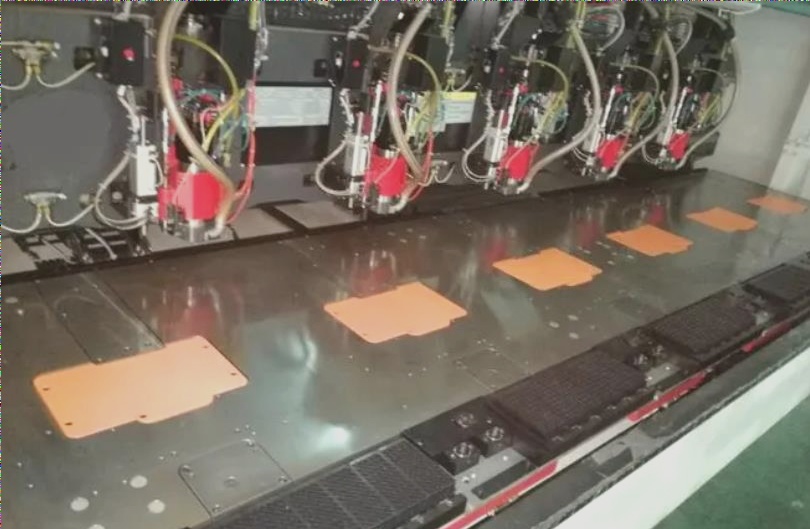

7. **Baking Method and Preservation Method of PCB Circuit Boards**

⑴Large circuit boards (16 PORT and above, including 16 PORT) should be placed flat, with a stack of up to 30 pieces. Open the oven and remove the PCB within 10 minutes of baking to cool down.

⑵Small and medium-sized PCBs (8 PORT and below) should be placed horizontally. Stack up to 40 pieces, with an unlimited number of vertical types. Open the oven within 10 minutes of baking, remove the PCB, and place it flat to cool naturally.

The specific storage time and baking temperature for PCB circuit boards are influenced not only by the production capacity and process of the PCB manufacturer but also significantly by the region.

PCBs made with the OSP anti-oxidation process and pure immersion gold process typically have a shelf life of 6 months after packaging. Baking is generally not recommended for OSP process PCBs.

PCB preservation and baking time vary with the region. In southern areas, such as Guangdong and Guangxi, where “returning to the south” weather occurs in March and April with frequent rain and high humidity, PCBs must be used within 24 hours of exposure to air to avoid oxidation. After opening, it is best to use the PCB within 8 hours. For PCBs that require baking, the baking time will be longer. In northern areas, where the weather is generally drier, storage time can be longer, and baking time can be shorter. The typical baking temperature is 120±5 degrees Celsius, with baking time determined based on specific conditions.

For PCB storage time, baking time, and temperature, detailed analysis and specific decisions must be made based on PCB management and control specifications, considering the production capacity, technology, region, and season of different circuit board manufacturers.

Material Operation Process in PCBA Production

PCBA production and processing plants have established regulations for operating and using “material operation procedures” during production. The aim is to effectively implement quality standards for material use, ensure materials are used within their expiration dates, and maintain proper storage conditions to prevent quality issues.

Standard Material Operation Process in PCBA Production:

1. The quality assurance department sets the validity period for each batch of raw materials according to relevant standards.

2. The warehouse manager prints material labels (indicating product name, serial number, specification/quality standard, incoming material) in the ERP system based on the production date, PASS stamp from the quality inspection department, and the internal validity period. Labels include quantity, current stock, production date, effective use date, and re-inspection date, which is generally the first week of the month of the effective use date.

3. The warehouse manager should check the validity period of stock materials at the beginning of each month and notify the quality assurance department of materials nearing expiration and approaching the re-inspection date.

4. For materials approaching their expiry date, the warehouse manager should promptly complete a re-inspection form to notify the quality inspection department for re-inspection and replace the materials with a yellow status sign.

5. Upon receiving the re-inspection notice from the warehouse manager, the quality inspection department should arrange re-inspection promptly and issue an inspection report in a timely manner.

6. For materials that pass re-inspection, the quality assurance department should approve their use within the specified time limit. For materials that cannot be used, the purchasing department should negotiate with the supplier for exchange, or the warehouse manager should apply to the quality assurance department to process them as non-conforming products.

7. Unqualified materials should be treated as non-conforming products.

8. SMT solder paste should be used within 6 months of the production date. Solder paste exceeding this period will be treated as a non-conforming product, following the same process as other unqualified products.

2. PCB circuit board baking can alleviate internal stress, stabilizing the PCB’s dimensions and reducing warpage.

3. **Advantages of Baking:** Baking dries the moisture in the pad, enhancing the soldering effect and reducing false soldering and repair rates.

4. **Disadvantages of Baking:** Baking may alter the color of the PCB, impacting its appearance.

5. The OSP process typically has a 6-month shelf life after packaging. If this period is exceeded, the board generally needs to be returned to the PCB manufacturer for rework.

6. Baking usually occurs at 100-120°C for about 2 hours—avoid overbaking! Boards should be used within 24 hours of exposure to air to prevent oxidation (this depends on the supplier’s capability; some OSPs can last longer, but it’s best to use them within 8 hours of unpacking).

7. **Baking Method and Preservation Method of PCB Circuit Boards**

⑴Large circuit boards (16 PORT and above, including 16 PORT) should be placed flat, with a stack of up to 30 pieces. Open the oven and remove the PCB within 10 minutes of baking to cool down.

⑵Small and medium-sized PCBs (8 PORT and below) should be placed horizontally. Stack up to 40 pieces, with an unlimited number of vertical types. Open the oven within 10 minutes of baking, remove the PCB, and place it flat to cool naturally.

The specific storage time and baking temperature for PCB circuit boards are influenced not only by the production capacity and process of the PCB manufacturer but also significantly by the region.

PCBs made with the OSP anti-oxidation process and pure immersion gold process typically have a shelf life of 6 months after packaging. Baking is generally not recommended for OSP process PCBs.

PCB preservation and baking time vary with the region. In southern areas, such as Guangdong and Guangxi, where “returning to the south” weather occurs in March and April with frequent rain and high humidity, PCBs must be used within 24 hours of exposure to air to avoid oxidation. After opening, it is best to use the PCB within 8 hours. For PCBs that require baking, the baking time will be longer. In northern areas, where the weather is generally drier, storage time can be longer, and baking time can be shorter. The typical baking temperature is 120±5 degrees Celsius, with baking time determined based on specific conditions.

For PCB storage time, baking time, and temperature, detailed analysis and specific decisions must be made based on PCB management and control specifications, considering the production capacity, technology, region, and season of different circuit board manufacturers.

Material Operation Process in PCBA Production

PCBA production and processing plants have established regulations for operating and using “material operation procedures” during production. The aim is to effectively implement quality standards for material use, ensure materials are used within their expiration dates, and maintain proper storage conditions to prevent quality issues.

Standard Material Operation Process in PCBA Production:

1. The quality assurance department sets the validity period for each batch of raw materials according to relevant standards.

2. The warehouse manager prints material labels (indicating product name, serial number, specification/quality standard, incoming material) in the ERP system based on the production date, PASS stamp from the quality inspection department, and the internal validity period. Labels include quantity, current stock, production date, effective use date, and re-inspection date, which is generally the first week of the month of the effective use date.

3. The warehouse manager should check the validity period of stock materials at the beginning of each month and notify the quality assurance department of materials nearing expiration and approaching the re-inspection date.

4. For materials approaching their expiry date, the warehouse manager should promptly complete a re-inspection form to notify the quality inspection department for re-inspection and replace the materials with a yellow status sign.

5. Upon receiving the re-inspection notice from the warehouse manager, the quality inspection department should arrange re-inspection promptly and issue an inspection report in a timely manner.

6. For materials that pass re-inspection, the quality assurance department should approve their use within the specified time limit. For materials that cannot be used, the purchasing department should negotiate with the supplier for exchange, or the warehouse manager should apply to the quality assurance department to process them as non-conforming products.

7. Unqualified materials should be treated as non-conforming products.

8. SMT solder paste should be used within 6 months of the production date. Solder paste exceeding this period will be treated as a non-conforming product, following the same process as other unqualified products.