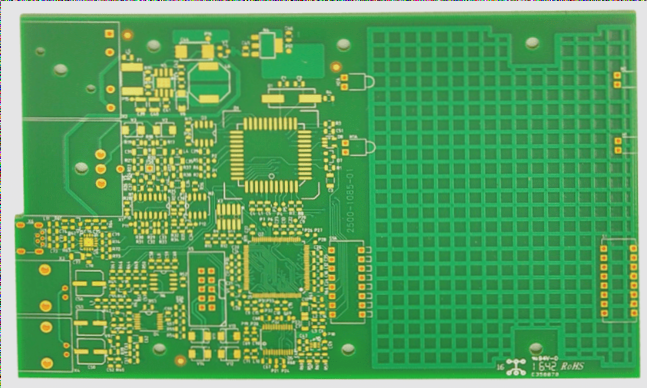

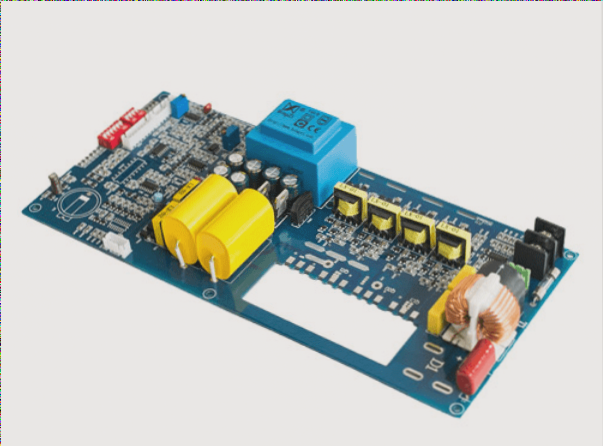

Factors Contributing to the Popularity of PCBA Foundry Services

PCBA foundry technology focuses on the design and manufacturing of printed circuit boards, with applications spanning medical equipment, lighting, and military uses, while its popularity grows due to small-batch production, reduced costs, and improved production processes.

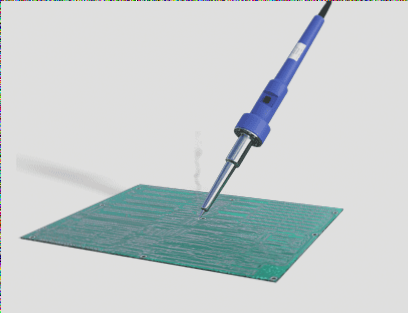

The Benefits of PCBA Manufacturing and Lead-Free Processes

The article discusses the distinctions and advantages of leaded versus lead-free PCBA foundry processes, highlighting differences in alloy composition, melting points, costs, and process management, while emphasizing the trend towards lead-free solutions due to health risks associated with lead.

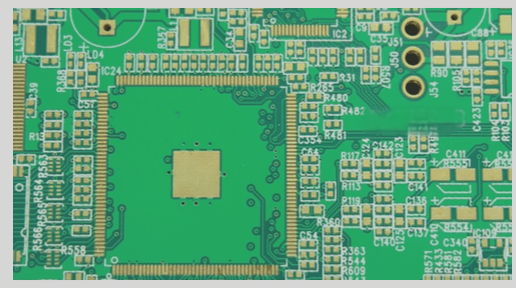

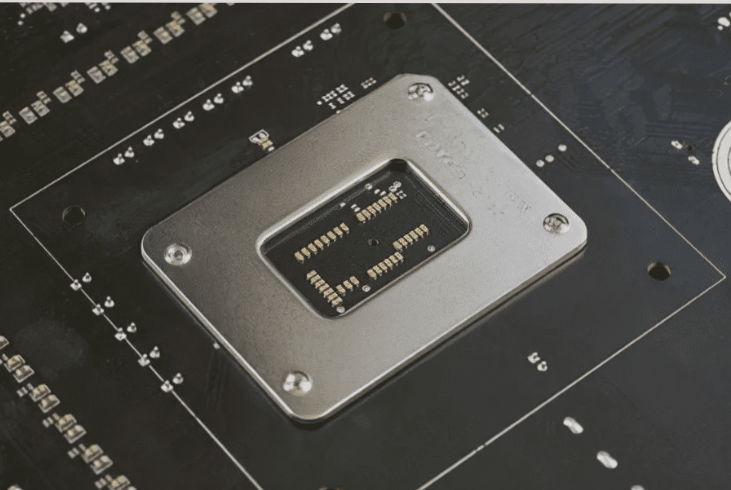

Emphasis on PCBA production processes and quality control measures.

Quality control in PCBA processing is crucial due to the complexity of links and production processes, requiring thorough inspections and systematic measures at every stage to prevent defects and ensure high-quality output.

The most prevalent quality inspection method in PCBA manufacturing.

The common quality inspections in PCBA processing include material testing, incoming material verification, solder inspections, PCB board checks, solder paste management, SMT machine adjustments, reflow soldering control, and final QA inspections to ensure product quality before delivery.

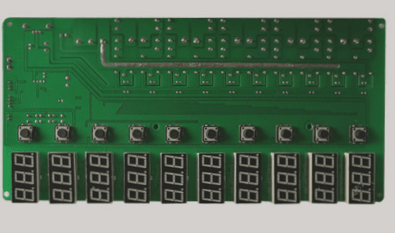

Skills for Evaluating the Quality of FPC Circuit Boards

As science and technology advance, the rise of FPC circuit boards has led to concerns about pricing and quality among manufacturers, prompting the need for reliable methods to assess their quality, such as evaluating appearance and adhering to specific standards.

The distinctions between welding flexible printed circuits (FPC) and printed circuit boards (PCB), as well as the FPC mold.

The assembly of components on flexible circuit boards (FPC) poses unique challenges compared to rigid PCBs, necessitating specific techniques like stabilization, preheating, and various mold types to address issues related to flexibility, moisture absorption, and precision cutting.

Parameter Specifications for PCB Design of Tablet PCs

The rise of tablet computers has driven significant changes in computing technology, particularly in the demand for advanced battery solutions like polymer lithium batteries, which offer superior design and safety features, leading to specific PCB design strategies that ensure efficient power management and protection for these devices.

FPC solder mask and cover layer specifications, along with FPC testing methodologies.

FPC solder masks and cover layers serve as insulators in flexible circuit boards, with distinct roles and thicknesses; the cover layer is thicker and often used in conjunction with solder masks for enhanced reliability, while the latter offers better bending resistance and is crucial for ultra-thin designs, requiring careful testing and standards to ensure quality and minimize waste.

What are the disadvantages of PCBA foundry costs?

Understanding the costs and drawbacks of PCBA foundry materials is essential, as they influence both pricing and quality assurance in the production process.

The distinction between flexible and rigid PCBs, including FPC soldering techniques.

The distinction between PCB hard boards, FPC soft boards, and rigid-flexible boards lies in their structure and applications, with FPCs being lightweight and bendable, while the soldering process for FPCs involves manual drag soldering techniques and specific control parameters to ensure quality connections.