The Controversy Surrounding PCB Cloning

A PCB copy board, also known as a circuit board clone, involves reverse engineering electronic products to recreate their PCB files and documentation, sparking ongoing controversies regarding technological ethics and legal implications in the industry.

How to calculate the quotation for a PCB circuit board?

The PCB quotation fee includes material, drilling, processing, and management costs, with prices influenced by material type, thickness, and surface treatment processes, requiring a detailed calculation process that varies by product and manufacturer capabilities.

What factors influence the pricing of PCBs?

PCB pricing is influenced by various factors, including material types, production processes, complexity, customer requirements, manufacturer differences, payment methods, and geographic location, leading to significant price variability.

How should the cost of a PCB be accurately determined?

The cost calculation for circuit boards involves various factors, including material management, labor, and manufacturing processes, with emphasis on minimizing waste and improving operational efficiency to control costs effectively.

What are the different layers involved in PCB circuit board design?

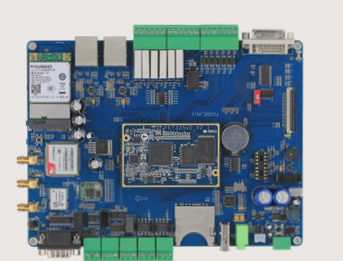

For beginners in electronic design, understanding the various layers of a PCB can be overwhelming, but it’s essential for effective construction, as these layers include components, routing, power distribution, and protective features.

How to troubleshoot issues in a malfunctioning PCB?

To restore a malfunctioning circuit board in harsh environments, skilled debugging methods such as voltage measurement, signal injection, and sensory inspection (observe, listen, smell, and touch) are essential for identifying and fixing issues.

QuickPCB 2005 Color Copy Board Software Manual

The PCB duplication process involves scanning the original board, creating a bill of materials, using software to generate PCB files, fabricating the board, and testing the final product to ensure it matches the original’s performance.

The composition of PCB design for circuit boards.

The current PCB circuit board consists of key components including circuits, dielectric layers, holes, solder masks, silk screens, and surface finishes, which collectively enhance its density, reliability, designability, manufacturability, testability, assemblability, and maintainability.

Employ the PCB design process utilizing Protel 99 SE software.

The article provides a comprehensive overview of the PCB design process using Protel99 SE, highlighting key steps such as creating a project database, designing schematics, generating netlists, determining PCB shape and size, creating components, executing layout and routing, conducting inspections, and archiving files.

How does PCB design account for the entire signal bandwidth in line length matching?

The relationship between PCB trace length matching and differential pair frequencies highlights the importance of considering the entire signal bandwidth to meet wideband signal integrity metrics, as emphasized by recent standards like USB4, which address factors such as crosstalk, insertion loss, and impedance deviation.

العربية

العربية 简体中文

简体中文 Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 한국어

한국어 Português

Português Русский

Русский Español

Español ไทย

ไทย