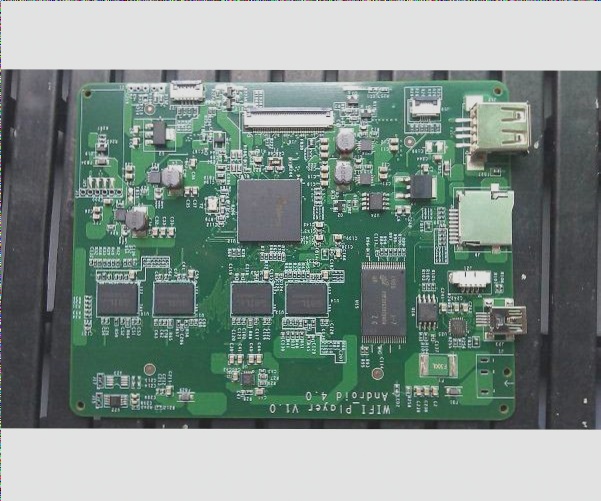

The aesthetic appearance of the green PCB substrate.

Green PCBs dominate the electronics industry due to their visibility during processing, environmental friendliness, and ease of inspection, despite no impact on performance, while various other colors are used primarily for differentiation.

Where is the critical point for the initial inspection of PCBA?

The initial inspection of PCBA processing is crucial for ensuring product quality and preventing defects, involving thorough verification of samples, components, and soldering quality before full production begins.

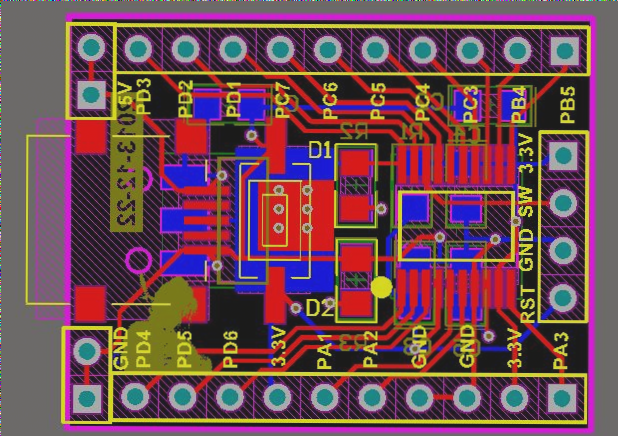

Utilizing filler blocks for pad design is a common misconception in PCB layout.

Understanding the complexities of PCB circuit board design is crucial, as issues like ambiguous processing levels, insufficient spacing, inadequate pad designs, and placement errors can lead to significant manufacturing challenges and functionality problems.

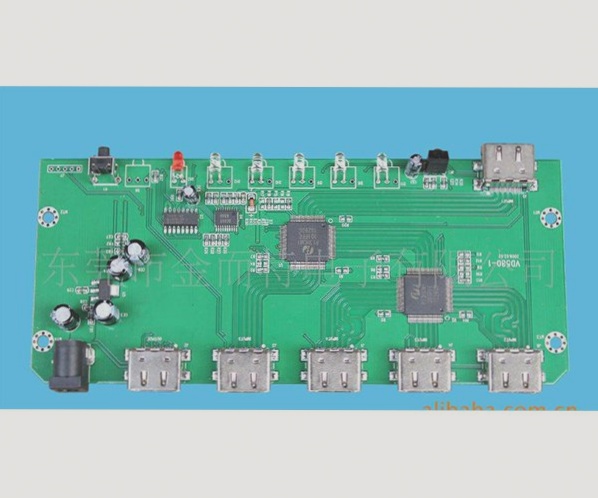

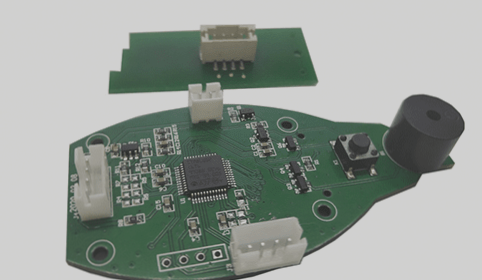

PCBA fabrication based on the specified assembly technique.

PCBA processing transforms PCBs into functional products through methods like SMT assembly and THT insertion, ultimately enabling nearly all electronic devices, with various assembly techniques tailored to component types and production conditions.

An effective approach for identifying failure issues in PCB assemblies.

Creating a PCB involves not just assembling components but also significant troubleshooting challenges, as many issues can arise post-assembly, often requiring careful inspection and replacement of faulty components, which can be rewarding for enthusiasts and engineers alike.

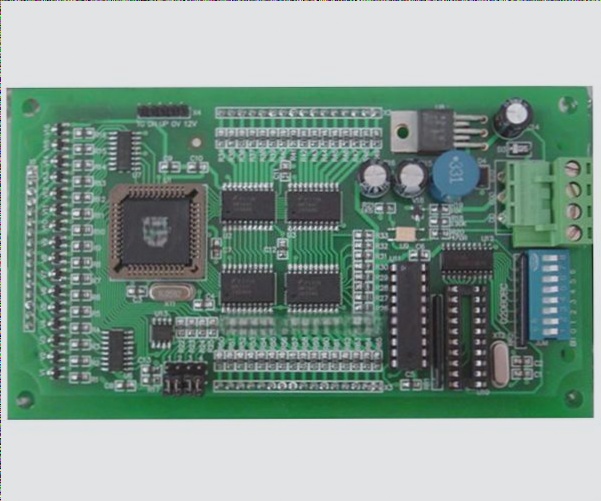

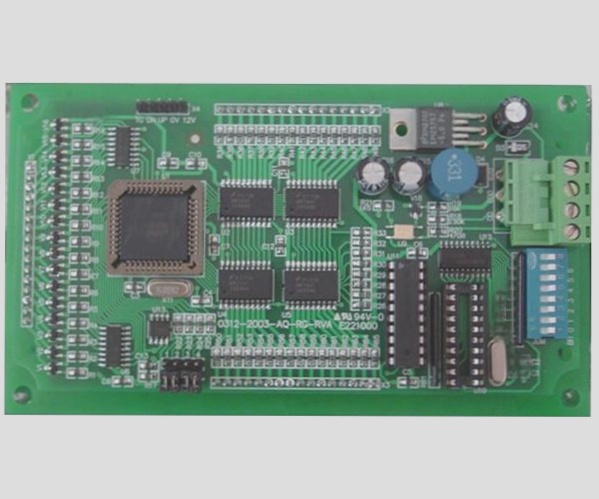

Methods for Processing PCB Circuit Boards in Wuxi SMD Fabrication

PCB circuit boards are small but essential in electronics, requiring precise soldering techniques and careful processing to ensure quality and efficiency in assembly.

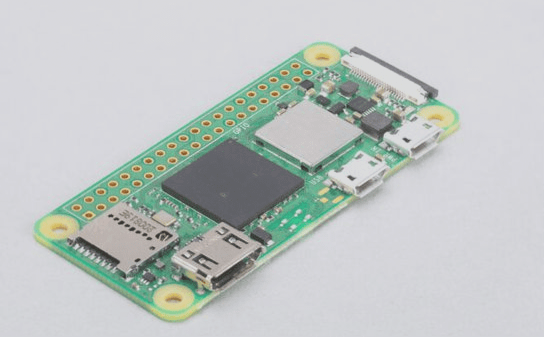

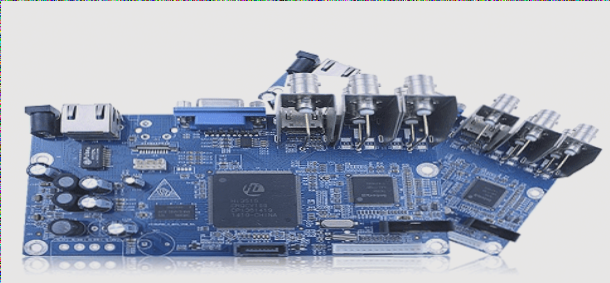

Is the processing of a PCBA board distinct from that of a PCB board?

PCBs (Printed Circuit Boards) are essential electronic components that serve as the foundation for electronic parts, while PCBA (Printed Circuit Board Assembly) refers to the process of populating these boards with components, highlighting the distinction between an unassembled board and its complete assembly.

What are the risks associated with contaminants in PCBA processing?

PCBA contaminants are surface impurities that can significantly impair the electrical, chemical, and physical performance of the assembly, with failures often linked to environmental factors and improper cleaning processes.

PCB Process Comparison: Spray Tin vs. Gold Plating vs. Immersion Gold

This discussion highlights the key differences between immersion gold and gold-plated PCB circuit boards, emphasizing that immersion gold offers superior thickness, solderability, oxidation resistance, and reduced risk of short circuits, making it a preferred choice for high-performance applications despite being softer and less wear-resistant than gold plating.

Specifications and Precautions for Three Anti-Paint Treatments on PCBs

The three-proof paint is a specialized coating for PCB circuit boards that protects against environmental damage, ensuring durability and reliability by providing moisture, dust, and corrosion resistance while allowing for higher power use and miniaturization of components.