What components are included in the functional testing of PCBA?

PCBA functional testing simulates operational conditions to verify functionality by measuring parameters like voltage and current, utilizing various testing methods and equipment, including test benches, dedicated test equipment, and advanced automatic test systems.

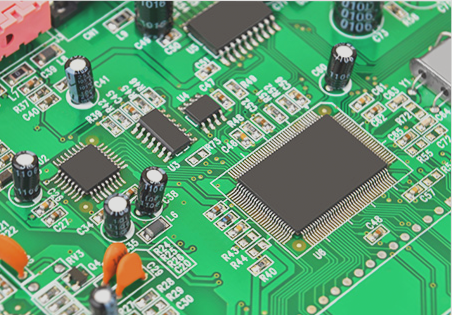

Essential Ten PCB Thermal Management Techniques to Master

Effective heat dissipation is crucial for PCB design to prevent overheating and ensure reliable electronic device performance, necessitating various techniques like enhanced copper usage, strategic component placement, and airflow optimization.

The PCBA team formulates a testing plan in accordance with established testing principles.

A well-structured PCBA test plan is crucial for enhancing debugging quality and testing efficiency, requiring detailed specifications on test content, equipment, methods, conditions, and safety procedures to ensure smooth operations and reliable results.

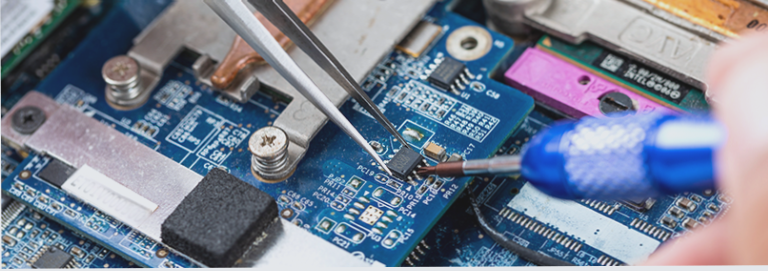

Guidelines for Repairing PCB Circuit Boards Without Schematics

To repair circuit boards without schematics, one must understand circuit principles, maintain an organized approach, summarize failure patterns, effectively retrieve information online, invest in essential testing equipment, and be adept at diagnosing various component failures while applying practical troubleshooting methods.

Why PCBA Testing is Essential and Its Key Components

PCBA testing is essential to ensure that assembled electronic components meet specified technical requirements and function properly, as variations in components can lead to significant performance deviations.

Why is it essential to prohibit halogens in PCB manufacturing at this time?

Halogen-free copper clad laminates are defined by their chlorine and bromine content, which must be below 0.09% and a total concentration of Cl + Br at or below 0.15%, offering safety and environmental benefits by minimizing toxic emissions during disposal or combustion.

The rationale for multi-layer PCBs typically not having an odd number of layers.

Multi-layer PCBs are predominantly even-numbered due to lower processing costs, better structural balance, and reduced bending risk compared to odd-numbered boards, which complicate production and increase costs.

Methods for Optimizing Solder Paste Application in PCB Assembly

The text outlines essential techniques for controlling solder paste printing in PCBA, emphasizing the importance of stencil adjustments, high-quality solder paste, automated printing processes, and thorough inspection methods to ensure optimal soldering quality.

What are the four electroplating techniques used in PCB circuit board manufacturing?

The article outlines four primary electroplating methods for circuit boards: finger row electroplating, through-hole electroplating, reel-linked selective plating, and brush plating, each serving specific functions to enhance electrical connectivity and surface quality.

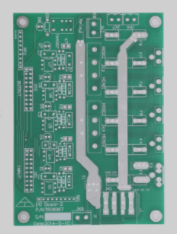

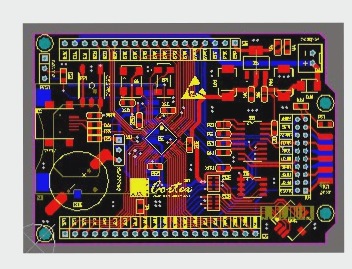

PCBA Process Flow Diagram and Manufacturing Steps

PCBA involves the assembly of surface-mounted and through-hole components using techniques like SMT and DIP, with various assembly processes such as full surface assembly and mixed assembly, emphasizing the importance of reflow soldering for efficiency and reliability.