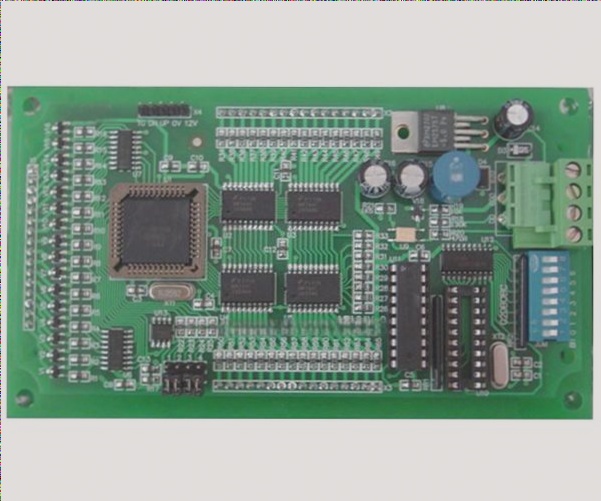

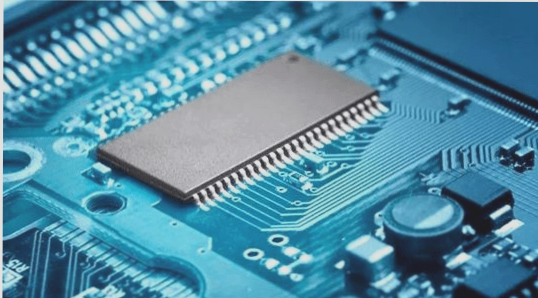

IPC-compliant PCB packaging design for surface mount devices.

To balance manufacturability and product performance in PCB design, the IPC-7351b standard guides the development of surface mount device packages, addressing issues like component specification mismatches and enhancing overall product quality.

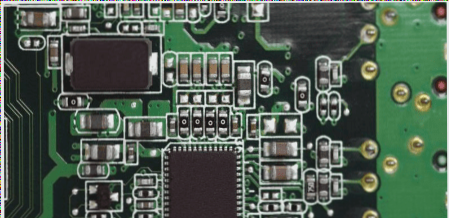

Key considerations essential for PCB inspection.

The text emphasizes key guidelines for PCB board inspection to ensure product quality, highlighting the importance of proper equipment use, understanding circuit principles, and maintaining safety to avoid damage to integrated circuits.

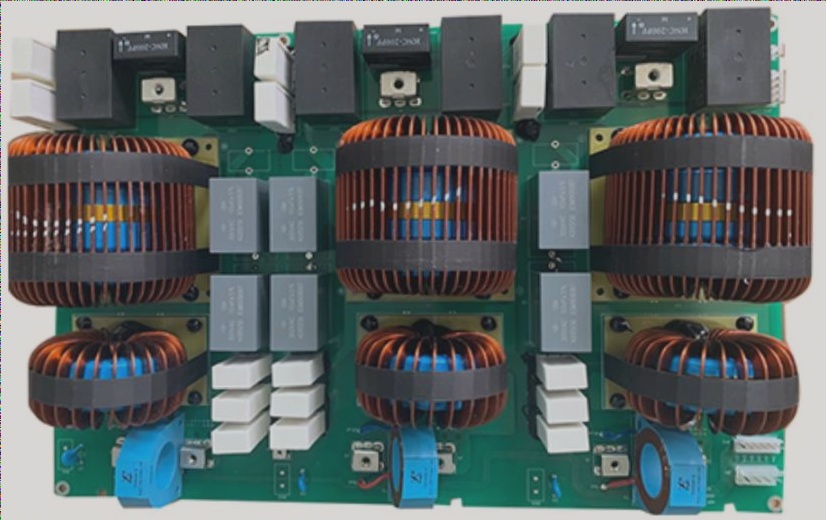

Typical Machinery and Applications in PCBA Processing

PCBA processing involves various machines, including printers, dispensers, and mounters, which enhance efficiency and yield through mechanical integration and advanced manufacturing techniques.

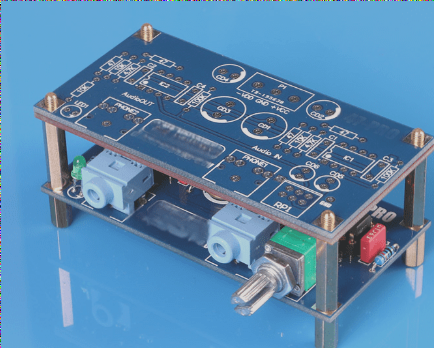

Guidelines for Repairing Printed Circuit Boards

Improper handling often damages printed circuit board (PCB) components, leading to potential repair options that depend on the situation and industry standards, particularly as outlined in the IPC-A-610 and IPC-7721 guidelines.

Methods for Mitigating RF Interference in PCB Interconnections.

This article discusses the challenges of interconnecting circuit board systems in RF design, focusing on techniques to manage electromagnetic effects, reduce crosstalk, and minimize return loss, as data rates and signal frequencies increase in PCB design.

How can we effectively manage the quality and processes in PCBA manufacturing?

A thorough pre-production meeting and stringent inspection of electronic components are essential for ensuring PCBA quality, minimizing defects, and reducing rework efforts.

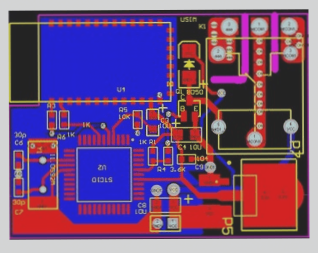

RF Interface and Circuit Design for PCB Development

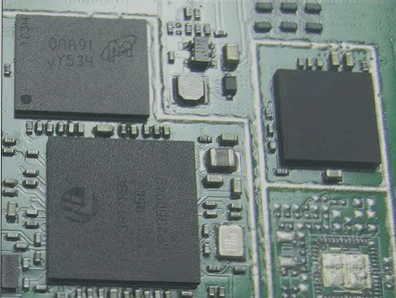

In PCB design for RF circuits, understanding fundamental RF attributes is crucial, as traditional tools like SPICE are inadequate; modern EDA software employs advanced algorithms for effective simulation, while design goals for both transmitters and receivers emphasize power efficiency, signal integrity, and interference management.

How to optimize labor and materials for PCBA development.

The PCBA industry is evolving to address design challenges and improve product quality by shifting from model-based to functional control, enhancing production processes, and integrating upgrade programs, while emphasizing careful material selection and robust circuit design to meet customer demands efficiently.

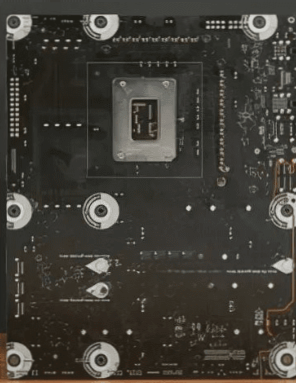

Comprehensive Analysis of PCB Failure Analysis Techniques: An Encyclopedia

PCBs are critical for electronic products, influencing performance and reliability, but face quality issues due to miniaturization and environmental standards, necessitating thorough failure analysis to identify root causes and solutions.

Key Principles for PCB Laminate Design

When designing a PCB, it’s crucial to balance the number of layers, ground and power planes against factors like functionality, signal integrity, and costs, often resulting in compromises that prioritize performance in high-speed and radio circuits.