PCB Board Cleaning Quality Standards

PCB board cleaning is essential in PCB production, modification design, and other manufacturing processes. Electronic processing plants and circuit board engineers follow specific standards for effective PCB cleaning. Here are the key aspects to consider:

1. Raw Material Quality Requirements:

- Tin-lead solder used for pressure processing must meet GB/T 31311 chemical composition requirements.

- Flux quality assessment includes factors like appearance, color, viscosity, and weldability.

2. Printed Circuit Board Cleaning Quality Requirements

In China, there is no unified standard for PCB cleaning quality. However, developed countries have specific requirements:

- J-STD-001B specifies limits for ionic contaminant content and flux residue.

- IPC-SA-61 and Mil-STD-2000A provide process-specific values for cleanliness.

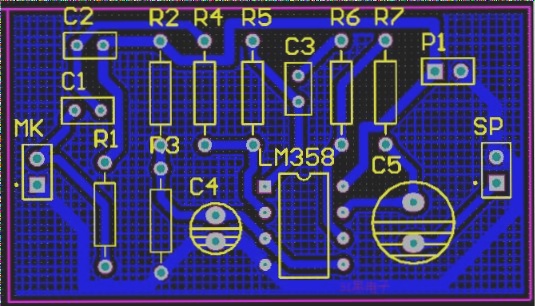

3. Detection Methods

Effective detection methods are crucial for assessing PCB cleaning quality:

- Visual Inspection: Directly inspect PCB surfaces for visible residues.

- ROSE Test Method: Measure resistivity before and after washing to assess cleanliness standards.

- Ion Chromatography Test Method: Determine ion content per square centimeter using an ion chromatograph.