PCB Boards: Essential Components in Electronics

PCB boards play a crucial role in various industries such as electronics, computers, and mechanical equipment. They act as a foundation for components and facilitate the flow of electricity. The most commonly used PCB boards are the 4-layer and 6-layer circuit boards, selected based on specific industry requirements.

Understanding Printed Circuit Boards

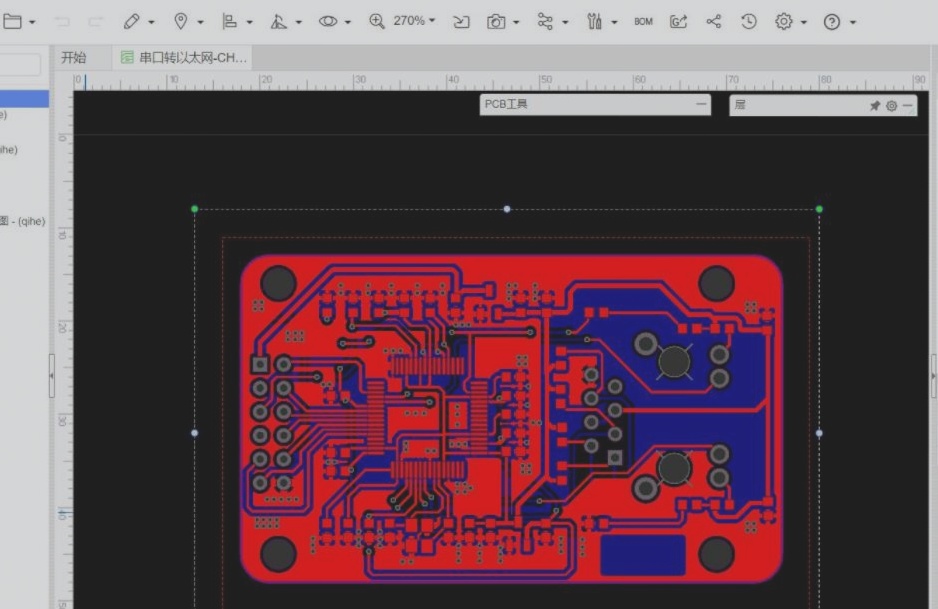

Printed Circuit Boards, also known as PCB boards or PWB (printed wiring boards), are constructed using an insulating base material with attached conductive patterns. These boards enable the interconnection of electronic components through holes like component holes and fastening holes. While often called “printed” circuit boards due to their production process, it’s important to note that they do not contain printed components, only wiring.

The Challenge of PCB Board Corrosion

Automatic soldering machines have revolutionized the soldering process for PCB boards, but they have also brought about the issue of PCB circuit board corrosion. WellCircuits Limited has successfully tackled this challenge through years of research and experience.

The Process of PCB Board Corrosion

PCB board corrosion involves the use of a corrosive liquid typically made of ferric chloride and water. The corrosion process begins from the board’s edge, and once the copper foil is corroded, it is crucial to halt the process to prevent damage to essential circuits. After cleaning the board, it is polished to reveal shiny copper foil and coated with a rosin solution to aid in soldering and prevent oxidation.

WellCircuits Limited: Your PCB Expert

WellCircuits Limited specializes in manufacturing high-precision circuit boards, including double-sided, multi-layer, impedance-controlled, and thick copper boards. Their product range covers HDI, thick copper, backplanes, rigid-flex, and more, catering to a wide range of customer needs.