Printed Circuit Board (PCB) External Connection Methods

As an essential component of any electronic system, a printed circuit board (PCB) cannot function independently and requires external connections for proper operation. These connections are crucial for linking printed boards with external components and equipment panels. Choosing the most suitable connection method is vital in PCB design, considering factors such as reliability, manufacturability, and cost.

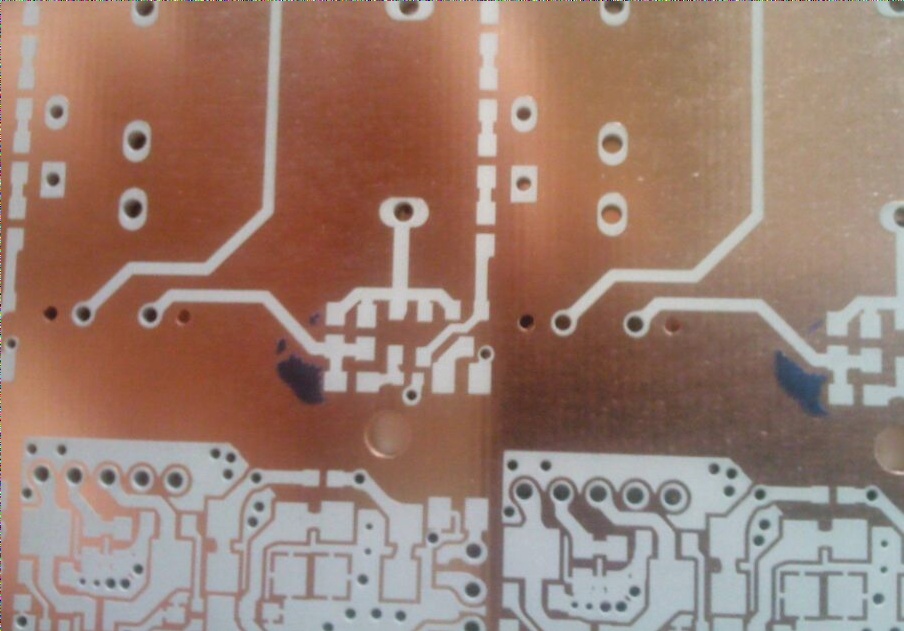

Soldering Wire Connection

One common method involves directly soldering the external connection points on the PCB to components or other parts outside the board using wires. This approach is simple, cost-effective, and reliable, minimizing failures due to poor contact. However, it may not be convenient for interchange and maintenance, making it suitable for designs with fewer external leads.

- Position soldering wire pads close to the PCB edge for easy maintenance.

- Use drilled holes near solder joints for wire connection strength.

- Neatly arrange and secure wires to prevent breakage.

PCB Cable Welding

Flat cables can connect two PCB boards reliably and are commonly used for creating integral parts of a PCB at a 90-degree angle. This method offers flexibility in board positioning and ensures a strong connection without errors.

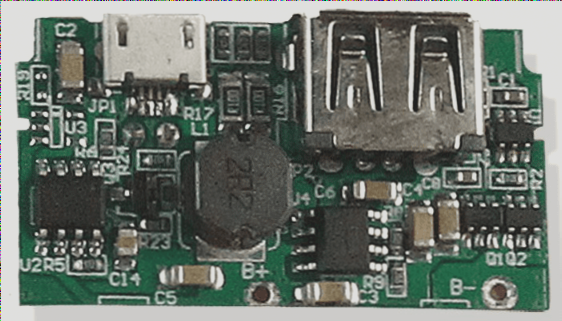

Connector Connections

In complex instruments, connector connections are preferred for their modular structure, enhancing product quality, reducing costs, and simplifying maintenance. This structure allows for easy identification and replacement of faulty boards, minimizing downtime.

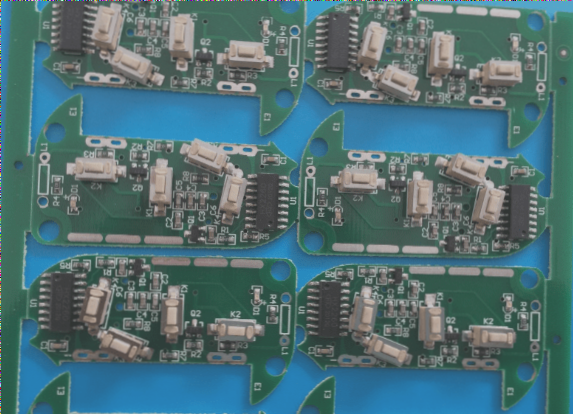

Printed Board Socket

Printed board socket connections involve creating a printed plug on the PCB edge to match a special socket. While offering easy assembly and maintenance, this method requires precision manufacturing and can increase PCB costs.

Standard Pin Connection

Standard pin connections are commonly used for external connections, especially in small instruments, facilitating mass production with parallel or perpendicular orientations.

WellCircuits Limited specializes in high-precision PCB manufacturing, including double-sided, multi-layer, impedance-controlled, and thick copper boards. Our product range covers HDI, thick copper, backplanes, rigid-flex, and more, tailored to meet diverse customer requirements.