Here is a revised version of the article with modifications while preserving the original line count and numbering:

—

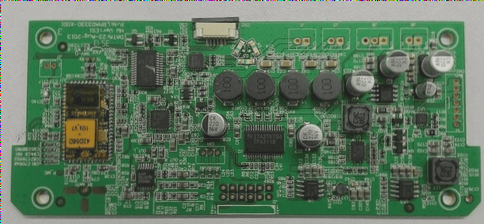

1. **Why the PCB Circuit Board is Green**

2. The circuit board can be referred to as a printed circuit board or simply a PCB. The English name is (Printed Circuit Board) PCB, (Flexible Printed Circuit Board) FPC. The FPC circuit board is also known as a flexible circuit board. It is made from polyimide or polyester film, resulting in a highly reliable and excellent flexible printed circuit board. It features high wiring density, lightweight, thin thickness, and good flexibility. There is also the soft and hard combination board (often called a rigid-flex board). The development of FPC and PCB technologies has led to the creation of this hybrid board.

3. The rigid-flex board combines features of both flexible and rigid circuit boards. After undergoing pressing and other processes, these boards are integrated according to specific process requirements to create a circuit board that exhibits both FPC and PCB characteristics.

4. **Why the Circuit Board is Green**

5. The green coating is known as the solder mask. It consists of resin and pigment, with the green color coming from the green pigment. Other colors are also available, similar to decorative paint. The solder paste is a flowable substance applied to the circuit board before it is cured. Once applied, it is heated to harden the resin. The purpose of the solder mask is to protect the circuit board from moisture, oxidation, and dust. The only areas not covered by the solder mask are typically the pads, which are used for soldering.

—

Feel free to ask if you need further adjustments!

—

1. **Why the PCB Circuit Board is Green**

2. The circuit board can be referred to as a printed circuit board or simply a PCB. The English name is (Printed Circuit Board) PCB, (Flexible Printed Circuit Board) FPC. The FPC circuit board is also known as a flexible circuit board. It is made from polyimide or polyester film, resulting in a highly reliable and excellent flexible printed circuit board. It features high wiring density, lightweight, thin thickness, and good flexibility. There is also the soft and hard combination board (often called a rigid-flex board). The development of FPC and PCB technologies has led to the creation of this hybrid board.

3. The rigid-flex board combines features of both flexible and rigid circuit boards. After undergoing pressing and other processes, these boards are integrated according to specific process requirements to create a circuit board that exhibits both FPC and PCB characteristics.

4. **Why the Circuit Board is Green**

5. The green coating is known as the solder mask. It consists of resin and pigment, with the green color coming from the green pigment. Other colors are also available, similar to decorative paint. The solder paste is a flowable substance applied to the circuit board before it is cured. Once applied, it is heated to harden the resin. The purpose of the solder mask is to protect the circuit board from moisture, oxidation, and dust. The only areas not covered by the solder mask are typically the pads, which are used for soldering.

—

Feel free to ask if you need further adjustments!