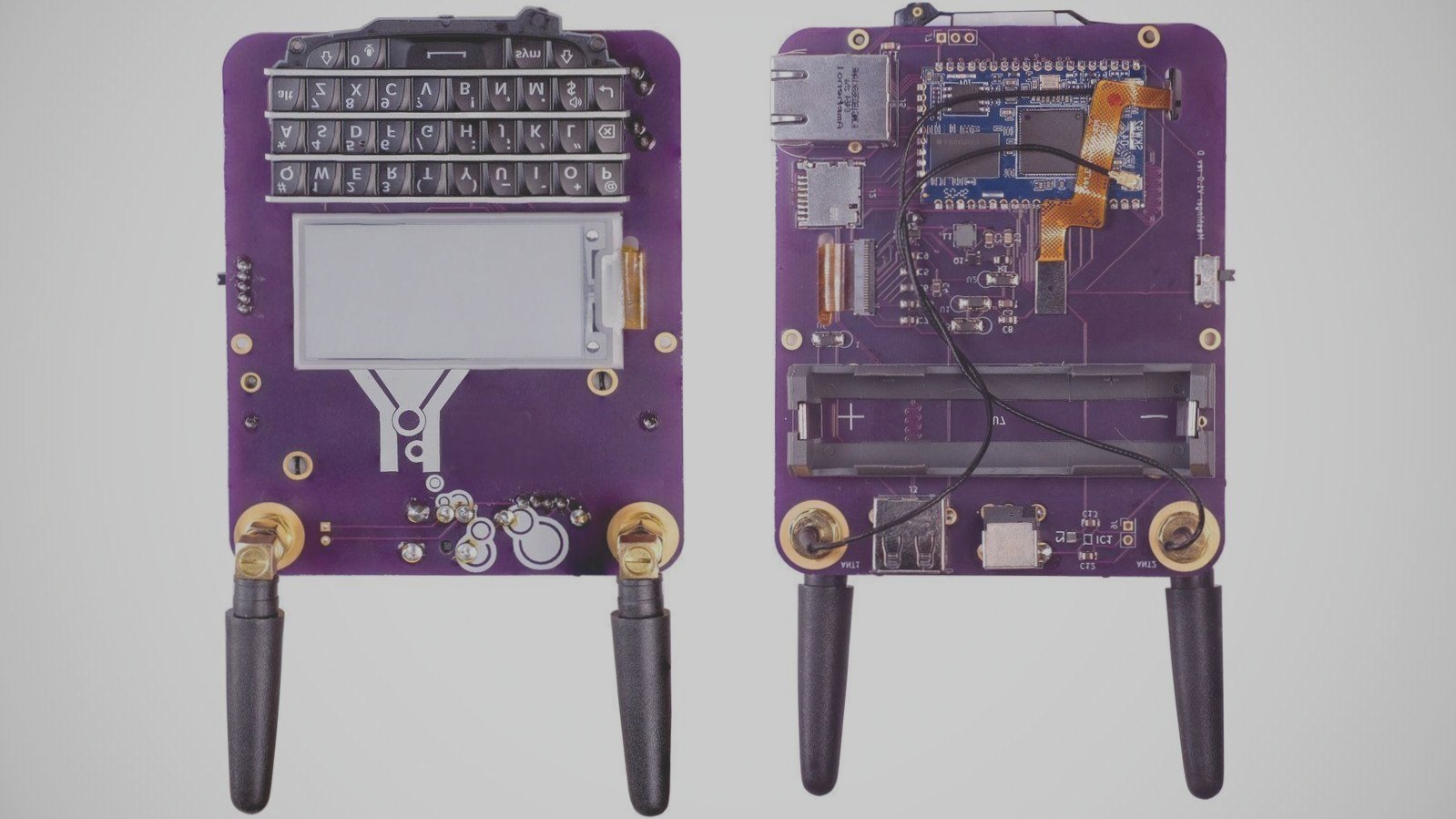

**Brief description of the difference between ordinary double-sided PCB boards and multi-layer PCB boards:**

The double-sided board consists of a medium layer, with wiring layers on both sides. In contrast, a multilayer board comprises multiple wiring layers, with a dielectric layer between each pair of layers, which can be made very thin. Multilayer circuit boards feature at least three conductive layers; two are located on the outer surfaces, while the remaining layer is embedded within the insulating substrate. Electrical connections between these layers are typically established through plated through holes on the cross-section of the circuit board.

**8-layer PCB proofing production—the purpose of blackening and browning:**

1. Eliminate contaminants such as oils and impurities from the surface;

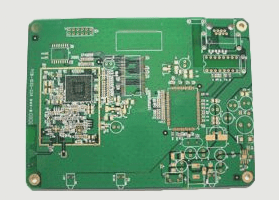

1. Laminating is the process of uniting each layer of circuits into a cohesive whole using B-stage prepreg. This bond is achieved through the mutual diffusion and penetration of macromolecules at the interface, followed by interweaving. The process bonds the various layers of circuits into a single entity with the help of prepreg.

2. Purpose: To press the discrete multilayer board together with the bonding sheet into a multilayer board of the required number of layers and thickness.

1. Typesetting involves layering copper foil, bonding sheet (prepreg), inner layer board, stainless steel, isolation board, kraft paper, outer layer steel plate, and other materials per process requirements. If the board exceeds six layers, pre-typesetting is essential. It lays out copper foil, bonding sheet (prepreg), inner layer board, stainless steel, isolation board, kraft paper, outer layer steel plate, and other materials based on the process criteria. For boards with more than six layers, pre-typesetting is necessary.

2. During the lamination process, the laminated circuit board is sent to the vacuum heat press. The heat energy supplied by the machine melts the resin in the resin sheet, thereby bonding the substrate and filling any gaps.

3. When considering lamination, designers must prioritize symmetry. The board will experience pressure and temperature during lamination, which can leave residual stress after completion. If the laminated board is not uniform on both sides, differing stresses can cause bending, adversely affecting PCB performance. Keyou Circuits specializes in high-precision multilayer circuit boards, which find applications in LCD modules, communication devices, instrumentation, industrial power supplies, digital and medical electronics, industrial control systems, LED modules, power energy, transportation, and high-tech fields such as R&D, automotive, and aerospace. Additionally, even within the same plane, uneven copper distribution can lead to varying resin flow rates at different points, resulting in inconsistent thicknesses. To mitigate these issues, factors such as copper distribution uniformity, stack symmetry, and the design of blind and buried vias must be carefully considered in PCB design.