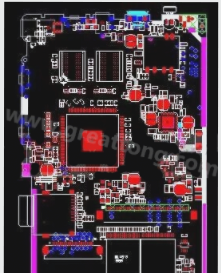

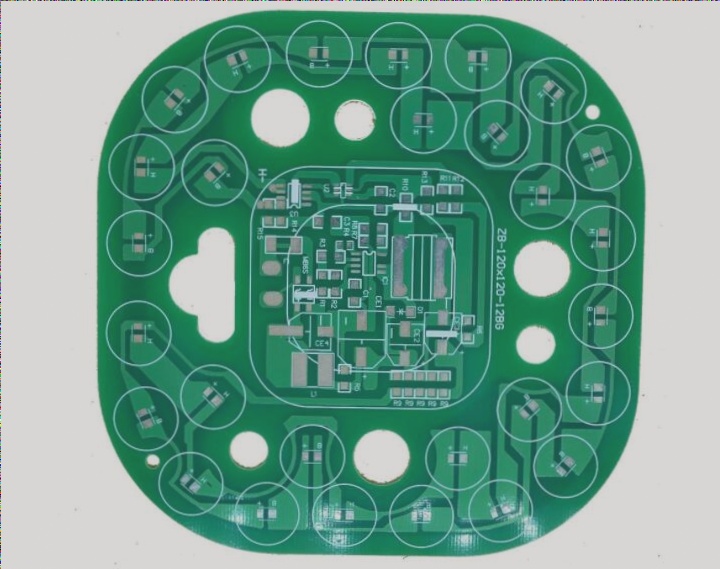

The PCB board is an integral part of many everyday electronic devices. If it malfunctions, the entire appliance may become inoperable. Today, I will explain how to check the PCB board.

1. Manual Visual Inspection of the PCB Board

Use a magnifying glass or a calibrated microscope to allow the operator to visually inspect the PCB and determine if it meets the required standards, as well as identify when corrective action is necessary.

**Advantages**: Low initial cost, no need for test fixtures.

**Disadvantages**: Due to the increasing complexity of PCB designs, with smaller wire spacings and components, this method is becoming less effective.

2. PCB Board Online Testing

Electrical performance testing is used to identify manufacturing defects and verify that analog, digital, and mixed-signal components meet specifications. Various testing methods are available, including bed-of-nail testers and flying probe testers.

**Advantages**: Low per-board testing cost, strong digital and functional testing capabilities, fast and comprehensive detection of short circuits and open circuits, firmware programming, high defect detection coverage, and easy programming.

**Disadvantages**: Requires test fixtures, setup and debugging time, high fixture manufacturing cost, and can be difficult to implement.

3. **PCB Board Function Test**

The functional system test involves using specialized test equipment at the middle and end stages of the production line to perform a comprehensive assessment of the circuit board’s functional modules, ensuring the quality of the board.

4. **Automatic Optical Inspection (AOI)**

Also known as automated visual inspection, this technique leverages optical principles and integrates various technologies such as image analysis, computer systems, and automation to detect and address defects encountered during production. It is a relatively new method for identifying manufacturing defects.

5. **Automatic X-ray Inspection (AXI)**

By exploiting the varying X-ray absorptivity of different materials, this method detects defects in the parts to be inspected through X-ray fluoroscopy. It is primarily used for detecting issues in ultra-fine pitch and high-density circuit boards, such as bridging, missing chips, misalignment, and other defects occurring during the assembly process. Additionally, X-ray imaging can identify internal defects in IC chips. This is currently the only technique that effectively tests the soldering quality of ball grid arrays (BGAs) and detects blocked solder balls.

**Advantages**: Capable of detecting BGA solder quality and embedded components, as well as providing high-precision insights into internal conditions of the product.

**Disadvantages**: High cost.

6. **Laser Detection System**

This is the latest advancement in PCB testing technology. It uses a laser beam to scan the printed circuit board, collects all relevant measurement data, and compares the actual values with preset qualification thresholds. This technology has been successfully applied to bare board testing and is now being considered for assembly board testing, with processing speeds sufficient for high-volume production lines.

**Advantages**: Rapid output, no need for fixtures, and access to areas not covered by visual inspection.

**Disadvantages**: High initial cost, with maintenance and operational challenges as key drawbacks.

1. Manual Visual Inspection of the PCB Board

Use a magnifying glass or a calibrated microscope to allow the operator to visually inspect the PCB and determine if it meets the required standards, as well as identify when corrective action is necessary.

**Advantages**: Low initial cost, no need for test fixtures.

**Disadvantages**: Due to the increasing complexity of PCB designs, with smaller wire spacings and components, this method is becoming less effective.

2. PCB Board Online Testing

Electrical performance testing is used to identify manufacturing defects and verify that analog, digital, and mixed-signal components meet specifications. Various testing methods are available, including bed-of-nail testers and flying probe testers.

**Advantages**: Low per-board testing cost, strong digital and functional testing capabilities, fast and comprehensive detection of short circuits and open circuits, firmware programming, high defect detection coverage, and easy programming.

**Disadvantages**: Requires test fixtures, setup and debugging time, high fixture manufacturing cost, and can be difficult to implement.

3. **PCB Board Function Test**

The functional system test involves using specialized test equipment at the middle and end stages of the production line to perform a comprehensive assessment of the circuit board’s functional modules, ensuring the quality of the board.

4. **Automatic Optical Inspection (AOI)**

Also known as automated visual inspection, this technique leverages optical principles and integrates various technologies such as image analysis, computer systems, and automation to detect and address defects encountered during production. It is a relatively new method for identifying manufacturing defects.

5. **Automatic X-ray Inspection (AXI)**

By exploiting the varying X-ray absorptivity of different materials, this method detects defects in the parts to be inspected through X-ray fluoroscopy. It is primarily used for detecting issues in ultra-fine pitch and high-density circuit boards, such as bridging, missing chips, misalignment, and other defects occurring during the assembly process. Additionally, X-ray imaging can identify internal defects in IC chips. This is currently the only technique that effectively tests the soldering quality of ball grid arrays (BGAs) and detects blocked solder balls.

**Advantages**: Capable of detecting BGA solder quality and embedded components, as well as providing high-precision insights into internal conditions of the product.

**Disadvantages**: High cost.

6. **Laser Detection System**

This is the latest advancement in PCB testing technology. It uses a laser beam to scan the printed circuit board, collects all relevant measurement data, and compares the actual values with preset qualification thresholds. This technology has been successfully applied to bare board testing and is now being considered for assembly board testing, with processing speeds sufficient for high-volume production lines.

**Advantages**: Rapid output, no need for fixtures, and access to areas not covered by visual inspection.

**Disadvantages**: High initial cost, with maintenance and operational challenges as key drawbacks.