Evolution of PCB Design in Product-Centric Approach

Traditionally, circuit boards played a central role in product design, with teams working independently until the prototyping stage. However, as product structures evolve, a shift towards a product-centric design method has emerged.

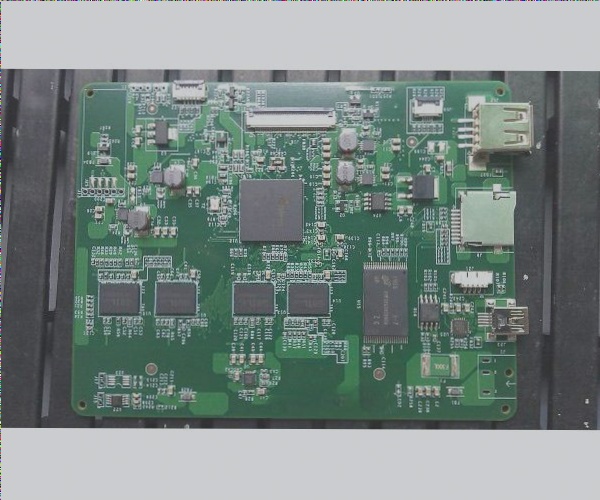

Impact of System-on-Chip (SoC) Ecosystem

The SoC has revolutionized hardware design by integrating multiple functions into a single chip, allowing engineers to utilize reference designs for development work. This shift has influenced the design process significantly.

Challenges in Product Packaging

Product packaging and aesthetic design are now crucial competitive factors, leading to the need for compact PCBs in tighter enclosures. This requires closer coordination among various design criteria to meet consumer demands.

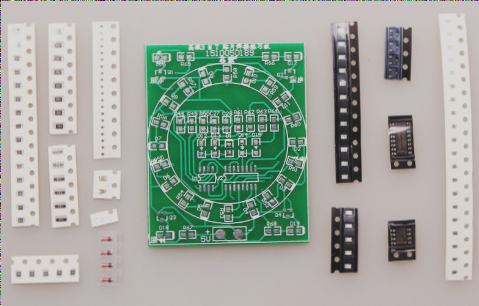

Advantages of Product-Centric Design

- Architectural verification for swift responses to evolving demands

- Assessment of product architecture against multiple design criteria

- Concurrent 2D/3D multi-board design planning

- Modular design for reusability

- Enhanced communication within supply chains

Adopting a product-centric design approach offers PCB manufacturers cost and time efficiencies, ensuring a competitive edge in the ever-evolving market.