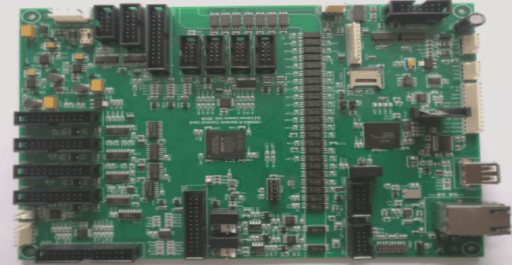

1. **PCB width and thickness:** The current-carrying capacity of copper traces etched onto a rigid printed circuit board. Attention should be given to the component height distribution on the PCB as well as its overall shape and size. For 1oz and 2oz traces, considering factors like the etching process, typical variations in copper foil thickness, and temperature fluctuations, a 10% reduction in the nominal value is permissible (as per the load current meter). Additionally, for PCB components with a protective coating (when the substrate thickness is under 0.032 inches and the copper foil exceeds 15oz), a reduction factor of 3 applies. For impregnated PCBs, a 30% reduction is acceptable.

2. **PCB line spacing:** The minimum line spacing must be calculated to prevent voltage breakdown or arcing between adjacent traces. The spacing is variable and primarily influenced by the following factors:

1) Peak voltage between adjacent traces.

2) Atmospheric pressure (maximum operating altitude).

3) Type of coating applied.

**4) Capacitive Coupling Parameters:**

Critical impedance components or high-frequency elements should be placed as close together as possible to minimize phase delay.

Transformers and inductors must be properly isolated to prevent coupling, and inductive signal traces should be positioned orthogonally, at right angles to each other. Components generating electrical noise due to magnetic field variations must be isolated or installed with strict guidelines to minimize excessive vibration.

**PCB Layout Inspection Checklist:**

1) Are the traces short and straight without compromising functionality?

2) Are the trace widths within the specified limits?

3) Is the minimum trace spacing maintained between traces, mounting holes, and pads?

4) Is the parallel routing of traces (including component leads) kept to a minimum to avoid close proximity?

5) Are sharp angles (90° or less) avoided in the routing?

**PCB Design Review Checklist:**

1) Verify the accuracy and logic of the schematic.

2) Ensure the component footprints in the schematic are correct.

3) Check the spacing between high-current and low-current areas, as well as isolation zones.

4) Confirm that the schematic and PCB layouts correspond, and that the netlist is complete.

5) Ensure the component packaging matches the physical components.

6) Verify the appropriate placement of components.

7) Ensure components are easy to install and remove.

8) Check that temperature-sensitive components are not placed too close to heat-generating elements.

9) Verify the correct spacing and orientation of transformer components.

10) Ensure proper alignment of connectors.

11) Ensure connectors are easily accessible for plugging and unplugging.

12) Review the input and output configuration.

13) Ensure proper separation of high-current and low-current areas.

14) Avoid mixing digital and analog traces too closely.

15) Ensure proper placement of components on the top and bottom layers.

16) Verify that components are correctly oriented and not mistakenly flipped.

17) Ensure the mounting holes align properly with component pins for easy insertion.

18) Check for any missing or faulty component leads (empty pads or “leaking” connections).

19) Verify that vias connecting traces on different layers are properly aligned and not causing potential disconnects.

20) Ensure that silkscreen labels are placed logically and do not obstruct components, to aid in assembly and maintenance.

21) For critical connections, ensure that vias are placed not only directly under pads but preferably at perforated connections to improve reliability.

22) Properly arrange power and signal traces in connectors to maintain signal integrity and minimize interference.

23) Ensure the pad sizes and solder holes are properly proportioned.

24) Place connectors near the edge of the PCB for easier handling and installation.

25) Verify that component labels match the actual components, and that components are placed in the same orientation wherever possible.

26) Ensure that power and ground traces are as wide as possible without violating design rules.

27) Typically, use horizontal traces on the top layer and vertical traces on the bottom layer, ensuring chamfers are no less than 90 degrees.

28) The size and placement of mounting holes should be optimized to minimize PCB bending stress.

29) Pay attention to the height distribution of components and the overall shape and size of the PCB to ensure easy assembly.

If your have any questions about PCB ,please contact me info@wellcircuits.com

2. **PCB line spacing:** The minimum line spacing must be calculated to prevent voltage breakdown or arcing between adjacent traces. The spacing is variable and primarily influenced by the following factors:

1) Peak voltage between adjacent traces.

2) Atmospheric pressure (maximum operating altitude).

3) Type of coating applied.

**4) Capacitive Coupling Parameters:**

Critical impedance components or high-frequency elements should be placed as close together as possible to minimize phase delay.

Transformers and inductors must be properly isolated to prevent coupling, and inductive signal traces should be positioned orthogonally, at right angles to each other. Components generating electrical noise due to magnetic field variations must be isolated or installed with strict guidelines to minimize excessive vibration.

**PCB Layout Inspection Checklist:**

1) Are the traces short and straight without compromising functionality?

2) Are the trace widths within the specified limits?

3) Is the minimum trace spacing maintained between traces, mounting holes, and pads?

4) Is the parallel routing of traces (including component leads) kept to a minimum to avoid close proximity?

5) Are sharp angles (90° or less) avoided in the routing?

**PCB Design Review Checklist:**

1) Verify the accuracy and logic of the schematic.

2) Ensure the component footprints in the schematic are correct.

3) Check the spacing between high-current and low-current areas, as well as isolation zones.

4) Confirm that the schematic and PCB layouts correspond, and that the netlist is complete.

5) Ensure the component packaging matches the physical components.

6) Verify the appropriate placement of components.

7) Ensure components are easy to install and remove.

8) Check that temperature-sensitive components are not placed too close to heat-generating elements.

9) Verify the correct spacing and orientation of transformer components.

10) Ensure proper alignment of connectors.

11) Ensure connectors are easily accessible for plugging and unplugging.

12) Review the input and output configuration.

13) Ensure proper separation of high-current and low-current areas.

14) Avoid mixing digital and analog traces too closely.

15) Ensure proper placement of components on the top and bottom layers.

16) Verify that components are correctly oriented and not mistakenly flipped.

17) Ensure the mounting holes align properly with component pins for easy insertion.

18) Check for any missing or faulty component leads (empty pads or “leaking” connections).

19) Verify that vias connecting traces on different layers are properly aligned and not causing potential disconnects.

20) Ensure that silkscreen labels are placed logically and do not obstruct components, to aid in assembly and maintenance.

21) For critical connections, ensure that vias are placed not only directly under pads but preferably at perforated connections to improve reliability.

22) Properly arrange power and signal traces in connectors to maintain signal integrity and minimize interference.

23) Ensure the pad sizes and solder holes are properly proportioned.

24) Place connectors near the edge of the PCB for easier handling and installation.

25) Verify that component labels match the actual components, and that components are placed in the same orientation wherever possible.

26) Ensure that power and ground traces are as wide as possible without violating design rules.

27) Typically, use horizontal traces on the top layer and vertical traces on the bottom layer, ensuring chamfers are no less than 90 degrees.

28) The size and placement of mounting holes should be optimized to minimize PCB bending stress.

29) Pay attention to the height distribution of components and the overall shape and size of the PCB to ensure easy assembly.

If your have any questions about PCB ,please contact me info@wellcircuits.com