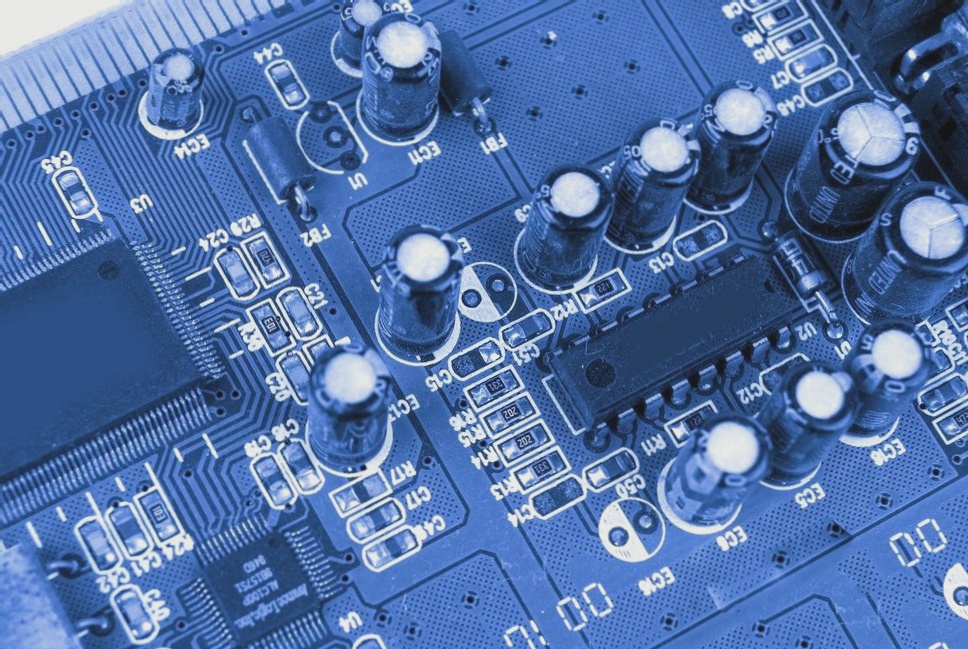

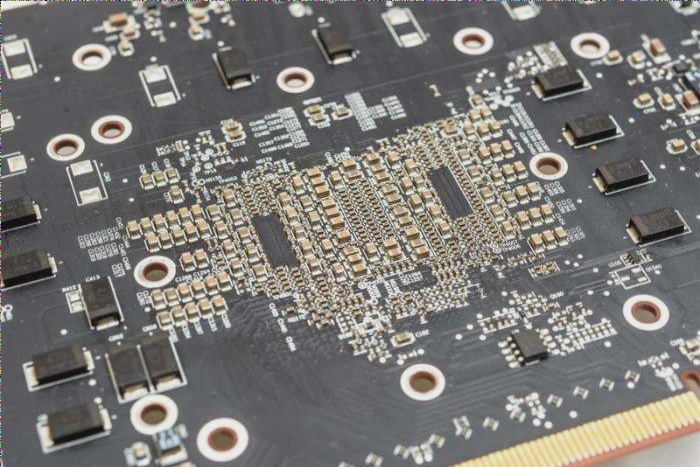

PCB is a critical component in today’s electronic industry. Once the design of the PCB is completed, failing to conduct a thorough inspection can lead to significant issues in future applications. Therefore, functional inspection of the PCB has become an essential step, providing greater assurance for subsequent production and ensuring that no major mistakes arise from temporary negligence. So, what inspection items should be carried out after PCB design?

1. **DFM Review of the PCB:** Verify that the PCB production meets the manufacturing process requirements, including wire width, spacing, routing, layout, vias, markings, and component orientation for wave soldering.

2. **Component and Pad Alignment Review:** Check if the actual SMT components purchased match the designed pads (indicated inconsistencies should be marked in red), and ensure they meet the placement machine’s spacing requirements.

3. **Three-Dimensional Graphics Generation:** Create three-dimensional graphics to verify that components do not interfere with each other, assess the reasonableness of the component layout, and evaluate factors like heat dissipation and SMT reflow soldering heat absorption.

4. **PCBA Production Line Optimization:** Optimize the placement sequence and material station locations. Input the existing placement machine data into the software, allocate components mounted on the board, determine the types and locations of Siemens pastes and other components, and assign material picking stations. This will help optimize the SMT patch processing program and save time. For multi-line production, component placement can also be optimized.

5. Work Instructions: Automatically generate work instructions for production line workers.

PCB Patch

6. Revision of Inspection Rules: The inspection rules can be modified. If the component spacing is smaller than 0.1mm, it can be adjusted to 0.2mm based on the specific model, manufacturer, and board complexity. For wire widths as small as 6mil, this can be changed to 5mil for high-density designs.

7. Support for Panasonic, Fuji, and Universal Placement Software: Automatically generate placement software, reducing programming time.

8. Automatically generate optimized steel plate graphics.

9. Automatically generate AOI and X-RAY programs.

10. Provide inspection reports.

11. Support various software formats.

2. Review the BOM, correct any errors such as spelling mistakes, and convert the BOM into the appropriate software format.

The above inspection items are necessary after PCB patch design. To use a simple analogy, these processes are like analyzing and correcting test papers to improve the answer sheets. With the electronics industry’s continuous evolution, PCBs, as essential carriers and connectors for electronic components, play a crucial role and are increasingly favored due to their design flexibility, ease of assembly, and maintainability.

1. **DFM Review of the PCB:** Verify that the PCB production meets the manufacturing process requirements, including wire width, spacing, routing, layout, vias, markings, and component orientation for wave soldering.

2. **Component and Pad Alignment Review:** Check if the actual SMT components purchased match the designed pads (indicated inconsistencies should be marked in red), and ensure they meet the placement machine’s spacing requirements.

3. **Three-Dimensional Graphics Generation:** Create three-dimensional graphics to verify that components do not interfere with each other, assess the reasonableness of the component layout, and evaluate factors like heat dissipation and SMT reflow soldering heat absorption.

4. **PCBA Production Line Optimization:** Optimize the placement sequence and material station locations. Input the existing placement machine data into the software, allocate components mounted on the board, determine the types and locations of Siemens pastes and other components, and assign material picking stations. This will help optimize the SMT patch processing program and save time. For multi-line production, component placement can also be optimized.

5. Work Instructions: Automatically generate work instructions for production line workers.

PCB Patch

6. Revision of Inspection Rules: The inspection rules can be modified. If the component spacing is smaller than 0.1mm, it can be adjusted to 0.2mm based on the specific model, manufacturer, and board complexity. For wire widths as small as 6mil, this can be changed to 5mil for high-density designs.

7. Support for Panasonic, Fuji, and Universal Placement Software: Automatically generate placement software, reducing programming time.

8. Automatically generate optimized steel plate graphics.

9. Automatically generate AOI and X-RAY programs.

10. Provide inspection reports.

11. Support various software formats.

2. Review the BOM, correct any errors such as spelling mistakes, and convert the BOM into the appropriate software format.

The above inspection items are necessary after PCB patch design. To use a simple analogy, these processes are like analyzing and correcting test papers to improve the answer sheets. With the electronics industry’s continuous evolution, PCBs, as essential carriers and connectors for electronic components, play a crucial role and are increasingly favored due to their design flexibility, ease of assembly, and maintainability.