There is a small battery in our mobile phone, something we touch every day. Let’s delve into it today.

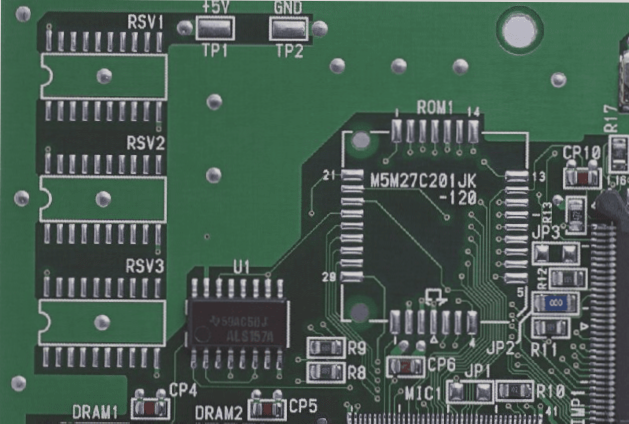

**PCB Components**

1. **Component Selection Criteria**

– **Protection IC Selection**

– High-end: MM3280H02, Seiko 8261AAGMD, Ricoh R5400N110FA

– Low-end: Composite IC, etc.

– **Special Requirements of Individual Customers**

– **MOSFET Selection**

– Mid-to-high end: Panasonic MTMC8E2A0L; AON3816, Magna, etc.

– Low-end: MOS 8205, etc.

– **Resistor-Capacitor**

– Capacitors: Use TDK, MARUTA brands, with X5R or X7R materials. Avoid Y5V capacitors.

– Resistors: Use TDK, Yageo brands, with materials of higher accuracy.

– **ID Resistance and NTC Resistance**

– Choose resistance value and accuracy based on customer needs. For NTC thermistors, determine the B value and package form according to space and wiring requirements of the PCM.

– **Fuse and PTC**

1. When the customer requests usage, the fuse should prioritize the 6A/0603 package. If the customer does not specify, but certification requirements arise, using a PTC or fuse must be considered. If neither customer requirements nor related certifications are applicable, the fuse and PTC can be omitted.

2. Design of PCB Protection Board

PCB Material: FR4 is the preferred material for protective boards, chosen for its fire resistance, mechanical strength, and cost-effectiveness. If the gold finger on the PCM must be exposed, it should be electroplated with a durable metal layer, such as: A) Thick gold plating with a thickness ≥ 0.25 μm B) Ordinary gold plating with a thickness ≥ 0.015 μm, and C) Hard plate copper skin with a thickness ≥ 1.0 ounce.

3. Electrical Performance Test Standards

Measuring Instrument Requirements:

– Voltmeter: Accuracy should be no less than 0.5%, with internal resistance of at least 10KΩ/V.

– Ammeter: Accuracy should be no less than 0.5%.

– Thermometer: Accuracy should be within ±0.5°C.

The current from the constant current source should be stable and adjustable, with variations within ±1%. The voltage from the constant voltage source should be adjustable, with variations within ±0.5%.

4. PCB Quotation Method:

When preparing to manufacture a PCBA board, create a detailed material form and confidently place an order after thorough comparison. The steps include:

1. Calculate the total material cost based on BOM and Gerber files.

2. Calculate the cost of SMT patches and DIP plug-ins.

3. Calculate the PCBA test costs (e.g., ICT, FCT).

4. Evaluate packaging and logistics.

5. Add a cost-based pricing adjustment according to the customer’s region and product characteristics, generally calculated as: quotation = cost * (1 + x%), where x requires comprehensive evaluation. Typically, x ranges around 20%. PCBA quotation reflects the expertise and vision of the sales staff and is crucial for improving the conversion rate of potential customers.

**PCB Components**

1. **Component Selection Criteria**

– **Protection IC Selection**

– High-end: MM3280H02, Seiko 8261AAGMD, Ricoh R5400N110FA

– Low-end: Composite IC, etc.

– **Special Requirements of Individual Customers**

– **MOSFET Selection**

– Mid-to-high end: Panasonic MTMC8E2A0L; AON3816, Magna, etc.

– Low-end: MOS 8205, etc.

– **Resistor-Capacitor**

– Capacitors: Use TDK, MARUTA brands, with X5R or X7R materials. Avoid Y5V capacitors.

– Resistors: Use TDK, Yageo brands, with materials of higher accuracy.

– **ID Resistance and NTC Resistance**

– Choose resistance value and accuracy based on customer needs. For NTC thermistors, determine the B value and package form according to space and wiring requirements of the PCM.

– **Fuse and PTC**

1. When the customer requests usage, the fuse should prioritize the 6A/0603 package. If the customer does not specify, but certification requirements arise, using a PTC or fuse must be considered. If neither customer requirements nor related certifications are applicable, the fuse and PTC can be omitted.

2. Design of PCB Protection Board

PCB Material: FR4 is the preferred material for protective boards, chosen for its fire resistance, mechanical strength, and cost-effectiveness. If the gold finger on the PCM must be exposed, it should be electroplated with a durable metal layer, such as: A) Thick gold plating with a thickness ≥ 0.25 μm B) Ordinary gold plating with a thickness ≥ 0.015 μm, and C) Hard plate copper skin with a thickness ≥ 1.0 ounce.

3. Electrical Performance Test Standards

Measuring Instrument Requirements:

– Voltmeter: Accuracy should be no less than 0.5%, with internal resistance of at least 10KΩ/V.

– Ammeter: Accuracy should be no less than 0.5%.

– Thermometer: Accuracy should be within ±0.5°C.

The current from the constant current source should be stable and adjustable, with variations within ±1%. The voltage from the constant voltage source should be adjustable, with variations within ±0.5%.

4. PCB Quotation Method:

When preparing to manufacture a PCBA board, create a detailed material form and confidently place an order after thorough comparison. The steps include:

1. Calculate the total material cost based on BOM and Gerber files.

2. Calculate the cost of SMT patches and DIP plug-ins.

3. Calculate the PCBA test costs (e.g., ICT, FCT).

4. Evaluate packaging and logistics.

5. Add a cost-based pricing adjustment according to the customer’s region and product characteristics, generally calculated as: quotation = cost * (1 + x%), where x requires comprehensive evaluation. Typically, x ranges around 20%. PCBA quotation reflects the expertise and vision of the sales staff and is crucial for improving the conversion rate of potential customers.