—

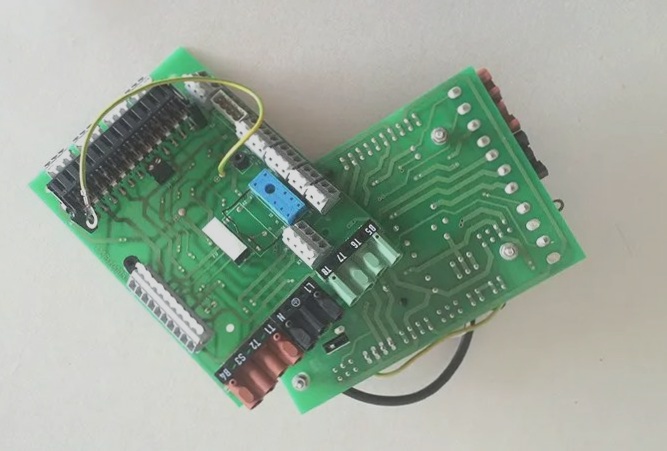

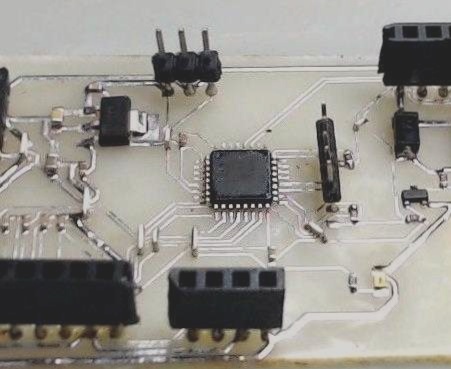

Ensuring PCB quality is fundamental for PCB manufacturers. However, various issues arise during production that can result in defects. Preventing these problems is crucial in PCB manufacturing. Below, PCB manufacturing engineers with decades of experience have summarized common causes of PCB defects and corresponding measures.

1. Pad overlap: During drilling, multiple drillings in the same spot can cause heavy holes or broken drills. This may result in larger or misaligned hole diameters. In multi-layer boards, simultaneous presence of both a connecting pad and an isolation pad in the same location can incorrectly isolate the PCB and cause connectivity issues.

2. Non-standard graphics layer: Poor design of graphic layers or excessive design elements such as unnecessary borders, broken lines, and labels can lead to misunderstandings and unnecessary scrap.

—

These changes aim to enhance clarity and readability while maintaining the technical details of PCB manufacturing concerns.

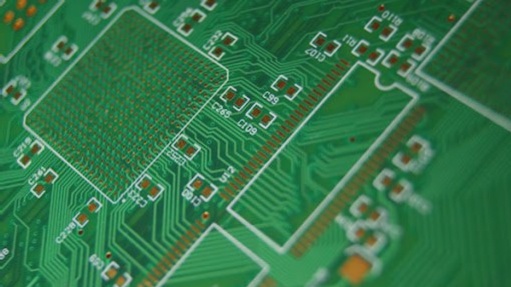

1. The character size is crucial: characters that are too small increase the difficulty of screen printing. Conversely, characters that are too large easily overlap during printing, making them hard to distinguish. This can also cover the SMD solder pads, complicating PCB testing and component soldering. Generally, character size should be > 40mil under normal circumstances.

2. Pad setting and hole diameter: For single-sided PCBs without soldering, pads are typically undrilled, necessitating a hole diameter of zero to avoid generating unnecessary drilling data during manufacturing.

3. Insufficient spacing between grid lines: When the spacing between grid lines < 0.3mm, the film may tear during the graphic transfer process in production, significantly increasing the complexity of PCB manufacturing.

4. Unclear frame shape: In multi-layer PCBs, the board edge is often framed, but improper alignment makes it difficult for manufacturers to discern the intended lines during production. Clear mechanical or BOARD layer designs for the standard frame are essential, ensuring that internal hollowed-out sections are distinct. Uneven graphic designs can affect uniform electroplating during constitutional processing, leading to board warping.

Sure, here is the revised and polished version of your text:

—

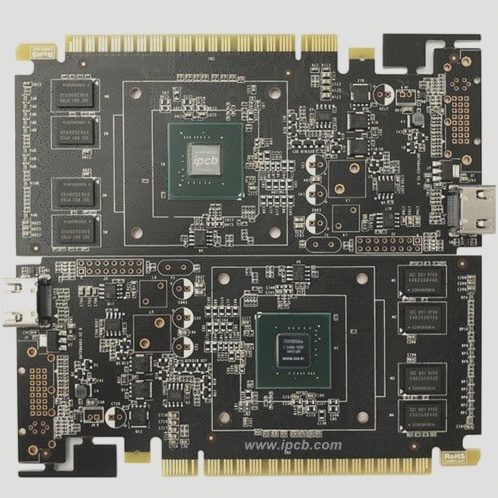

1. The special-shaped aperture should be set to 2:1/1.0mm. There should be at least 2 positioning holes with a diameter of >1.5mm on the PCB.

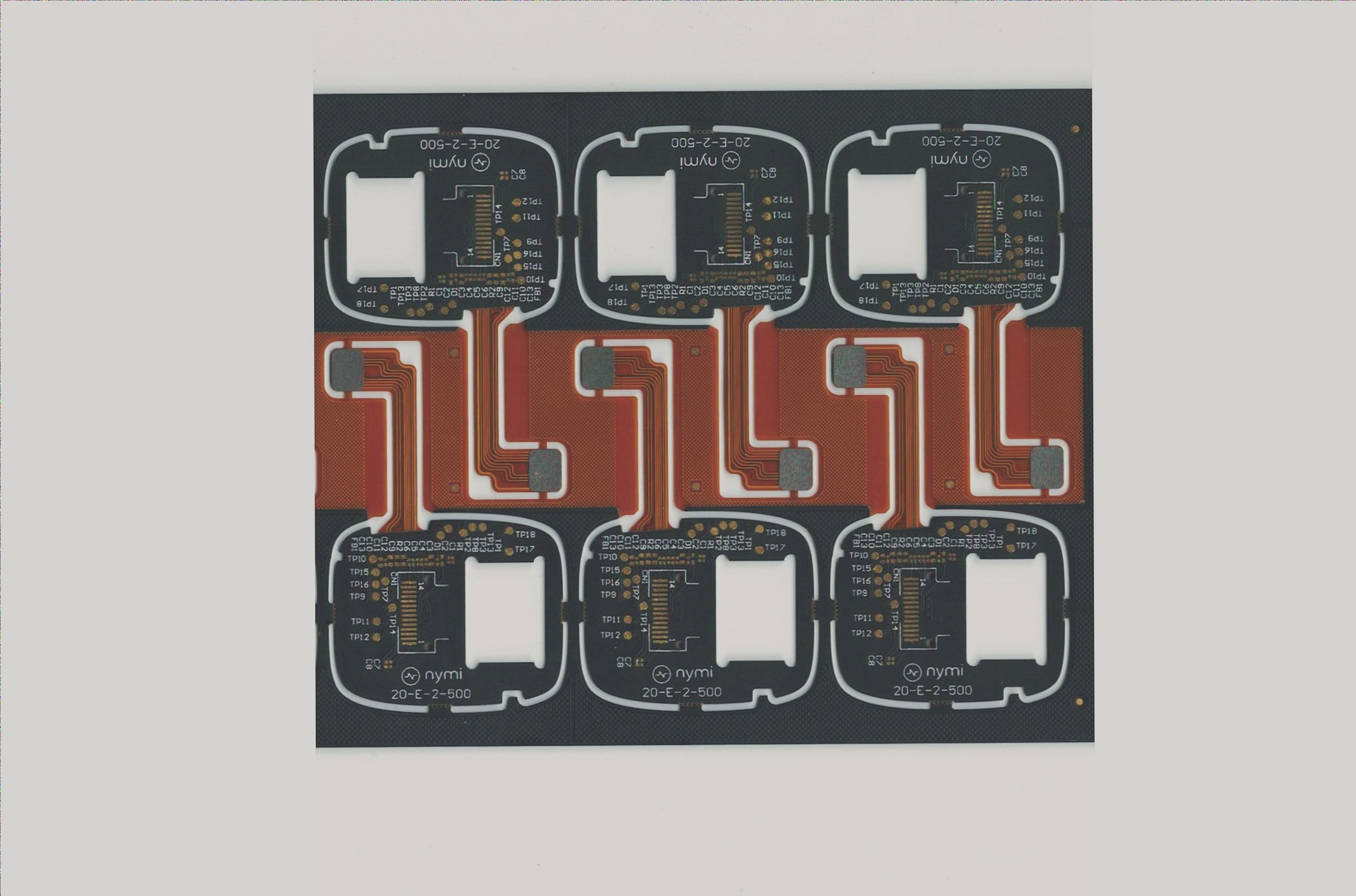

2. The inner layer arrangement in multi-layer PCBs can be problematic. Placing a heat dissipation pad on the isolation strip may result in disconnection after drilling. Narrow isolation strips make it difficult to accurately determine the grid. For buried and blind hole circuit boards, increasing the multi-layer board density by over 30% is recommended. Also, consider reducing the number of layers and overall size of the multi-layer board to enhance circuit board performance, particularly concerning characteristic impedance control.

3. The above points highlight common PCB defects. Further discoveries will be shared in the future. If you have suggestions or improvements, please feel free to share them. PCB manufacturing is highly complex, especially for HDI and multi-layer rigid and flexible PCBs, which demand advanced technology.